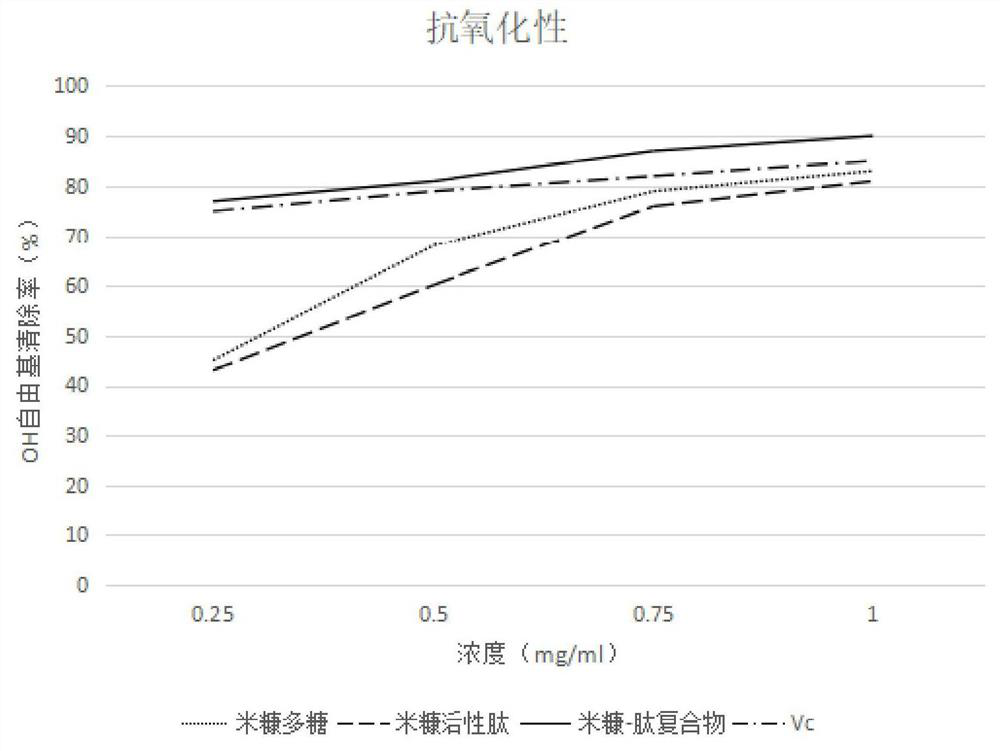

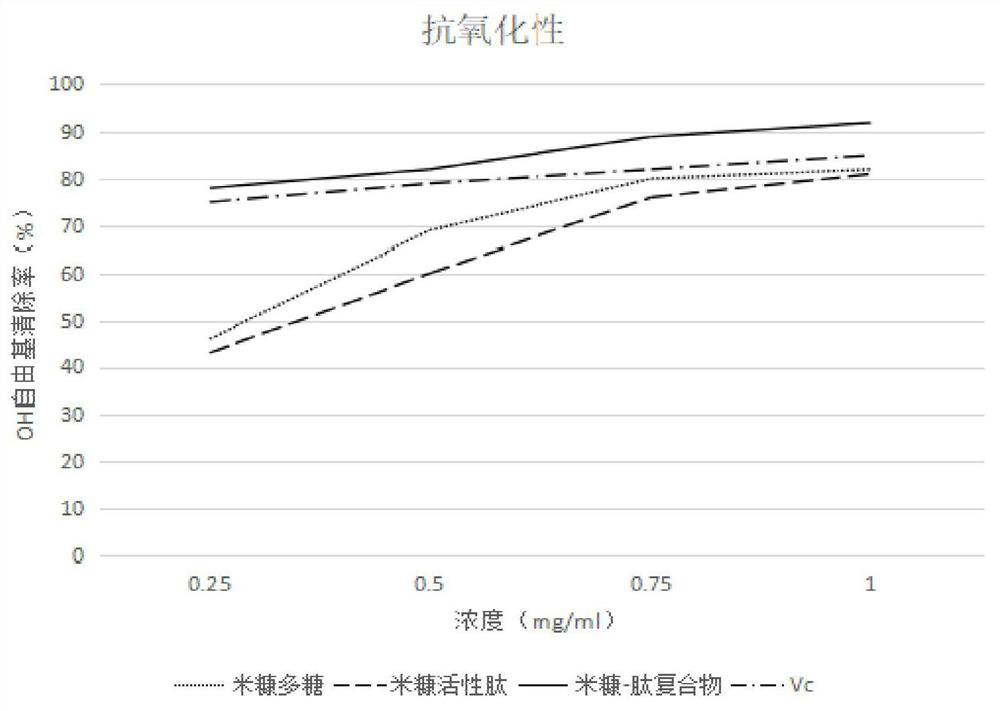

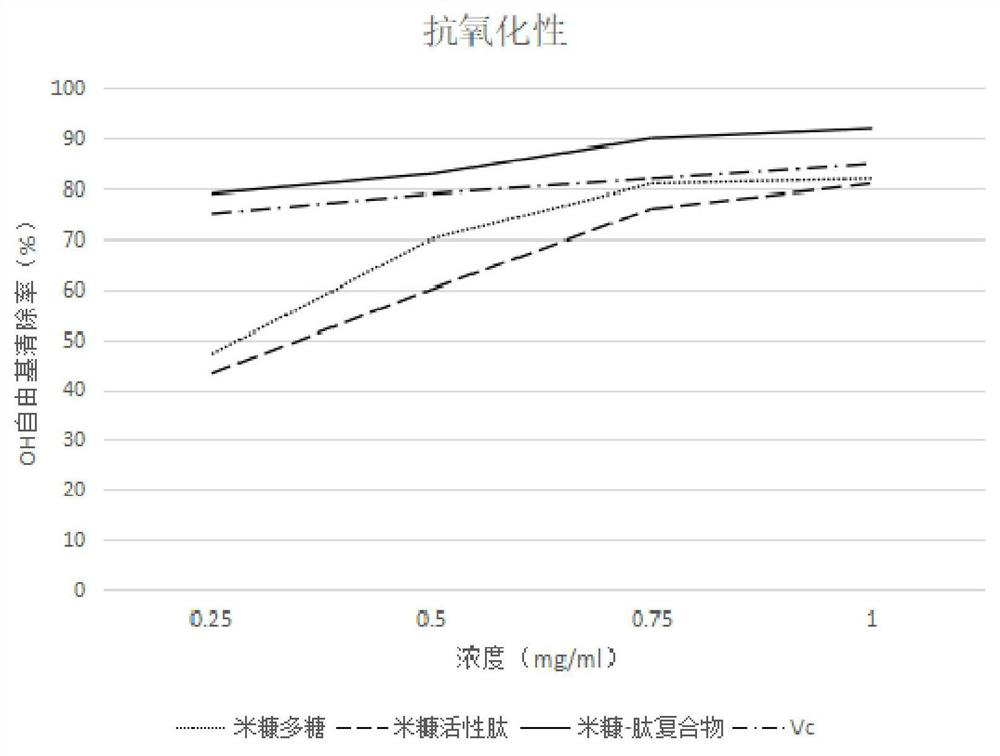

Rice bran polysaccharide-peptide compound with high oxidation resistance and preparation method thereof

A rice bran polysaccharide and peptide complex technology, which is applied in the field of rice bran compound preparation, can solve the problems of less than 20% total utilization rate and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A kind of preparation method of high antioxidant rice bran polysaccharide-peptide complex

[0027] 1. Extraction of rice bran polysaccharide

[0028] The defatted rice bran is pulverized and passed through a 60-mesh sieve, distilled water 15 times the amount of defatted rice bran is added, the pH is adjusted to 3.5 with tartaric acid aqueous solution, and softened by soaking for ten minutes. Adjust the upper and lower limit temperature of the low-temperature circulating pump to 10°C to -4°C to ensure that the internal temperature of the homogenizer is at room temperature. Pour the mixed material into a high-pressure homogenizer, adjust to 80MPa, and homogenize 4 times, each time for 20 minutes; the obtained homogeneous solution is centrifuged at 4000r / min for 15 minutes to remove the precipitate, adjust the pH to neutral, and freeze-dry to obtain a molecular weight of Rice bran polysaccharides between 10k and 50kDa.

[0029] 2. Maillard reaction of polysac...

Embodiment 2

[0037] Example 2 A kind of preparation method of high antioxidant rice bran polysaccharide-peptide complex

[0038] 1. Extraction of rice bran polysaccharide

[0039] The degreased rice bran is pulverized and passed through a 60-mesh sieve, distilled water 20 times the amount of the defatted rice bran is added, the pH is adjusted to 3.8 with tartaric acid aqueous solution, and softened by soaking for ten minutes. Adjust the upper and lower limit temperature of the low-temperature circulating pump to 10°C to -4°C to ensure that the internal temperature of the homogenizer is at room temperature. Pour the mixed material into a high-pressure homogenizer, adjust to 90MPa, and homogenize 5 times, each time for 20 minutes; the obtained homogeneous solution is centrifuged at 4000r / min for 20 minutes to remove the precipitate, and after adjusting the pH to neutral, freeze-dry to obtain a molecular weight of Rice bran polysaccharides between 10k and 50kDa.

[0040] 2. Maillard react...

Embodiment 3

[0048] Example 3 A kind of preparation method of high antioxidant rice bran polysaccharide-peptide complex

[0049] 1. Extraction of rice bran polysaccharide

[0050] The defatted rice bran is crushed and passed through a 60-mesh sieve, distilled water 25 times the amount of defatted rice bran is added, the pH is adjusted to 4.0 with tartaric acid aqueous solution, and softened by soaking for ten minutes. Adjust the upper and lower limit temperature of the low-temperature circulating pump to 10°C to -4°C to ensure that the internal temperature of the homogenizer is at room temperature. Pour the mixed material into a high-pressure homogenizer, and then adjust it to 95MPa. After the pressure is stable, homogenize it 6 times, 20 minutes each time; centrifuge the obtained homogeneous solution at 4000r / min for 20 minutes to remove the precipitate, adjust the pH to neutral, and carry out The rice bran polysaccharide with a molecular weight between 10k and 50kDa was obtained by fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com