Automatic taping and gluing device, carrier tape and taping method

A carrier tape and adhesive technology, which is applied in the directions of automatic packaging control, transportation and packaging, external support, etc., can solve problems such as offset, low work efficiency, and complex overall process, so as to reduce manufacturing costs, improve work efficiency, and simplify The effect of dispensing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

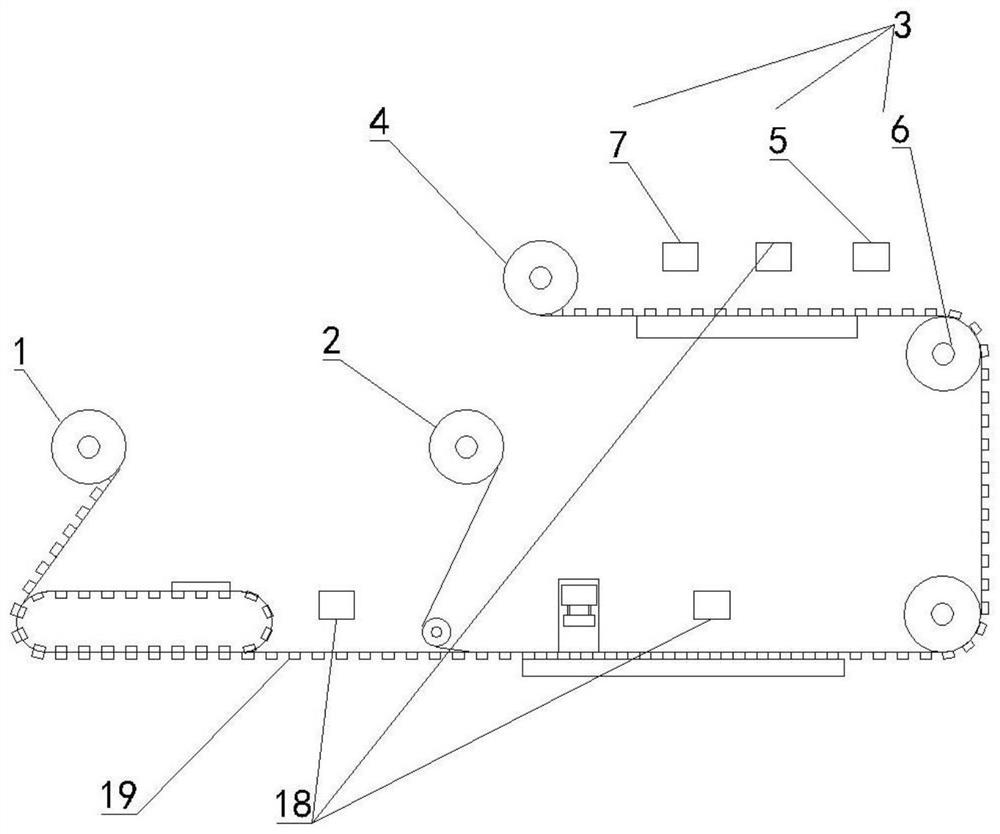

[0040] see figure 1 , an automatic tape and adhesive equipment, comprising:

[0041] The feeding mechanism 1 is used to transfer the workpiece 22 and place the workpiece 22 in the groove 20 of the carrier tape;

[0042] The sealing tape mechanism 2 is arranged at the lower station of the feeding mechanism 1, and the sealing tape mechanism 2 is used to seal the carrier tape with the workpiece 22 placed in the groove 20;

[0043]The glue spraying mechanism 3 is arranged at the lower station of the sealing tape mechanism 2, and the glue spraying mechanism 3 is used to align the through hole 21 of the carrier tape and spray glue to the workpiece 22 in the groove 20;

[0044] The winding mechanism 4 is arranged at the lower station of the glue spraying mechanism 3, and the winding mechanism 4 is used for winding the carrier tape after the glue spraying is completed.

[0045] Preferably, the glue spraying mechanism 3 includes a glue spraying assembly 5 and a first runner 6, and th...

Embodiment 2

[0057] Different from Embodiment 1, this implementation also has:

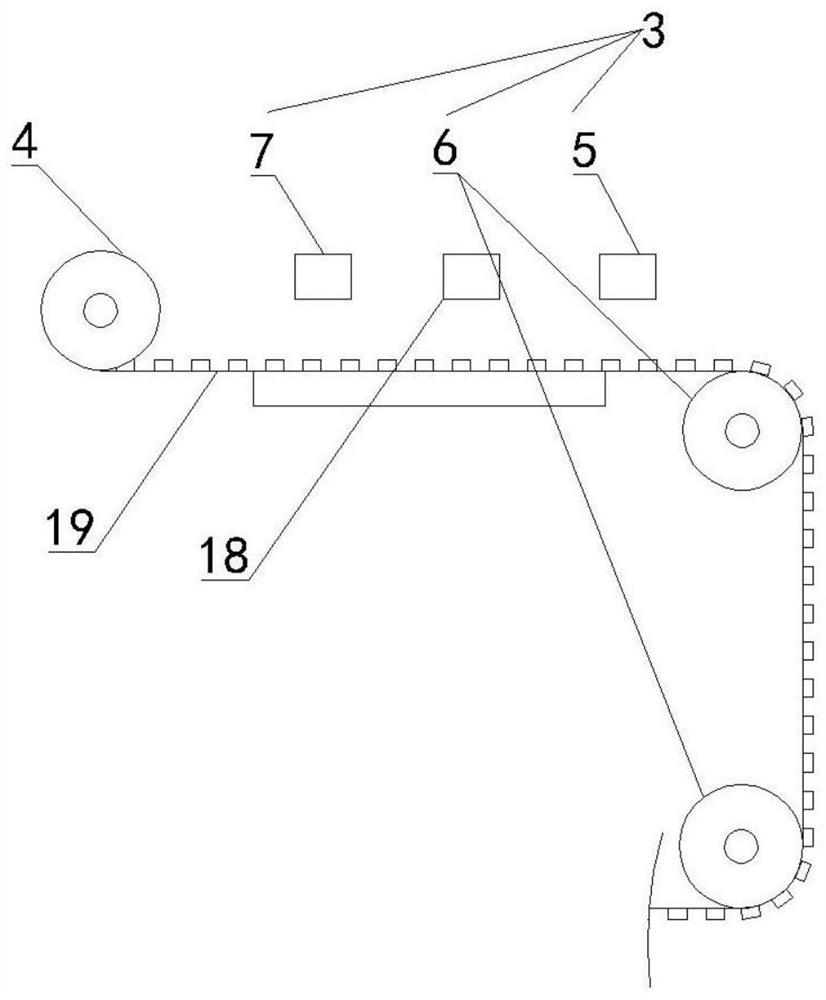

[0058] see figure 2 The glue spraying mechanism 3 also includes a back glue curing machine 7, which is arranged between the winding mechanism 4 and the glue spraying assembly 3, and the back glue curing machine 7 is used for curing in the groove 20 of glue.

[0059] In this embodiment, through the setting of the back glue curing machine 7, the back glue curing machine 7 is used to cure the glue in the groove 20, effectively reducing the fluidity of the glue, preventing the glue from flowing out, and at the same time, improving the adhesive force of the glue, Furthermore, the ability to fix the workpiece 22 is improved.

[0060] Specifically, the back glue curing machine 7 can be set as a UV lamp, also known as an ultraviolet lamp, which mainly uses the characteristics of ultraviolet rays to perform photochemical reactions, product curing, sterilization, medical inspection, etc. The UV lamp commonly used in...

Embodiment 3

[0063] Different from Embodiment 1, this embodiment also has:

[0064] see Figure 3-5 The feeding mechanism 1 includes a conveyor belt 8 and a tape carrier tray 9, the tape carrier tray 9 is rotatably arranged above the conveyor belt 8, and the tape carrier tray 9 is used for carrying and delivering the carrier tape 10 to the conveyor belt 8, so that The carrier tape is laminated and conveyed synchronously with the conveyor belt 8, and a plurality of feeding grooves 10 are arranged at equal intervals on the conveyor belt 8, and the feeding grooves 10 are used to correspond to the grooves 20 of the carrier tape one by one.

[0065] Preferably, the feeding mechanism 1 also includes a vibrating plate 11, a sensor 24, a feeding track 12 is provided between the vibrating plate 11 and the conveyor belt 8, the vibrating plate 11 is provided with a discharge port 13, the conveyor belt 8 is provided with a gap 14, and the feeding track One end of 12 is connected to the vibrating plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com