Preparation method of formaldehyde adsorption material

A technology for absorbing formaldehyde and carboxymethyl cellulose, which is applied in the field of air purification, can solve the problems of limited loading of chemical substances, long time, and long-term impact on the adsorption effect of formaldehyde during preparation, and achieves enhanced strength and wear resistance. Effect of specific surface area and adhesion enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

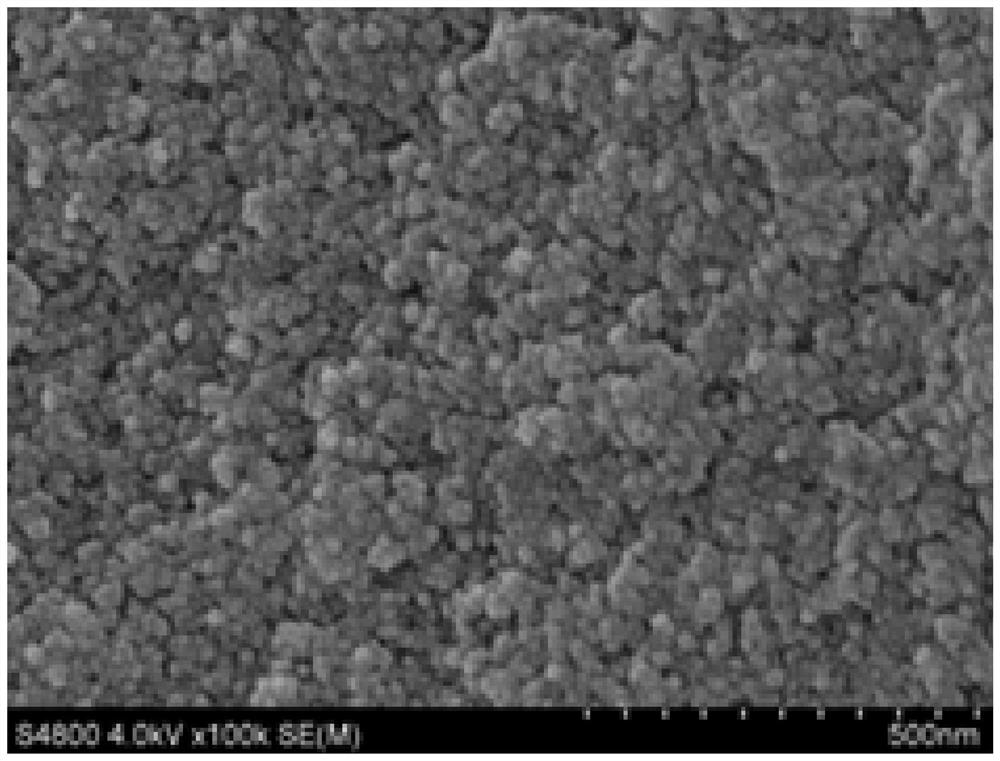

[0032] ① Place 40 parts of 100-mesh silica gel in the plasma reaction chamber, use 100W low-temperature plasma for 20 minutes under normal temperature and pressure oxygen flow, and take it out at room temperature.

[0033] ② During step 1), dissolve 5 parts of polyethyleneimine in 200 parts of deionized water, and disperse using a disperser at a dispersing speed of 20 r / min for 5 minutes.

[0034] ③ After step 2), dissolve 15 parts of ethylene urea in the mixed solution of step 2), and disperse using a disperser at a dispersing speed of 20r / min for 10 minutes.

[0035] ④ Add the silica gel powder after plasma treatment in step 1) to the solution in step 3) after dispersion, and the mixed suspension is continuously dispersed for 3 hours, and the dispersion speed is 20r / min.

[0036] ⑤ Filter the dispersed liquid through a 200-mesh gauze to leave effectively impregnated silica gel powder, put the powder in a glass plate, and dry it in a microwave drying equipment. The drying pow...

Embodiment 2

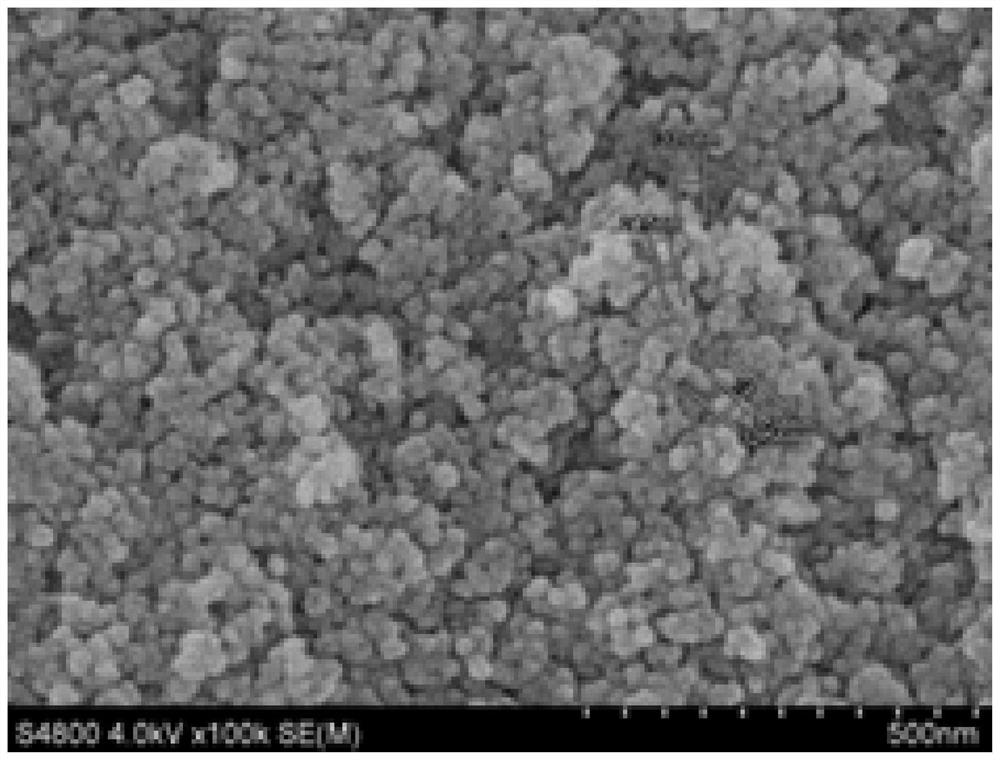

[0041] ① Place 15 parts of 100-mesh silica gel in the plasma reaction chamber, use 100W low-temperature plasma for 20 minutes under normal temperature and pressure oxygen flow, and take it out at room temperature.

[0042] ②During step 1), dissolve 10 parts of polyethyleneimine in 200 parts of deionized water and disperse using a disperser at a speed of 20 r / min for 5 minutes.

[0043] ③ After step 2), dissolve 5 parts of ethylene urea in the mixed solution of step 2), and disperse using a disperser at a dispersing speed of 20r / min for 10 minutes.

[0044] ④ Add the silica gel powder after plasma treatment in step 1) to the solution in step 3) after dispersion, and the mixed suspension is continuously dispersed for 3 hours, and the dispersion speed is 20r / min.

[0045] ⑤ Filter the dispersed liquid through a 200-mesh gauze to leave effectively impregnated silica gel powder, put the powder in a glass plate, and dry it in a microwave drying equipment. The drying power is set to ...

Embodiment 3

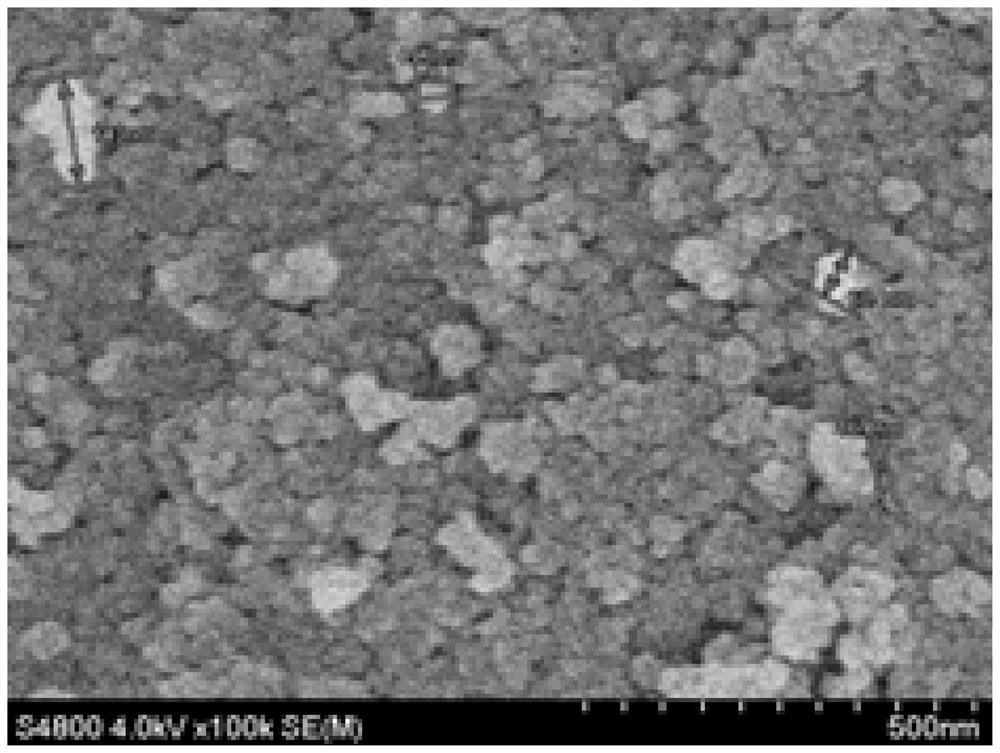

[0049] ① Place 15 parts of 100-mesh silica gel in the plasma reaction chamber, use 100W low-temperature plasma for 20 minutes under normal temperature and pressure oxygen flow, and take it out at room temperature.

[0050] ②During step 1), dissolve 10 parts of polyethyleneimine in 200 parts of deionized water and disperse using a disperser at a speed of 20 r / min for 5 minutes.

[0051] ③ After step 2), dissolve 5 parts of ammonium sulfate in the mixed solution of step 2), and disperse using a disperser at a dispersing speed of 20r / min for 10 minutes.

[0052] ④ Add the silica gel powder after plasma treatment in step 1) to the solution in step 3) after dispersion, and the mixed suspension is continuously dispersed for 3 hours, and the dispersion speed is 20r / min.

[0053] ⑤ Filter the dispersed liquid through a 200-mesh gauze to leave effectively impregnated silica gel powder, put the powder in a glass plate, and dry it in a microwave drying equipment. The drying power is set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com