Motor control system control parameter self-tuning device and tuning method thereof

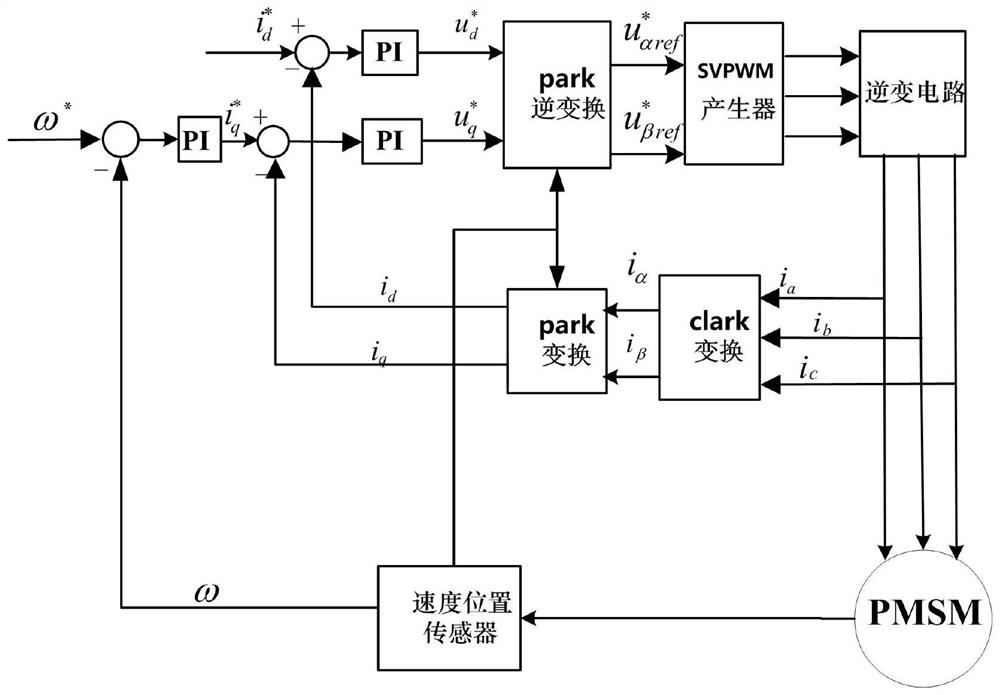

A technology of control parameters and motor control, applied in the direction of control system, motor control, vector control system, etc., can solve the problem of not being able to realize the self-tuning of multiple permanent magnet synchronous motors at the same time, and achieve the effect of highlighting the substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without making creative efforts belong to the protection scope of the present invention.

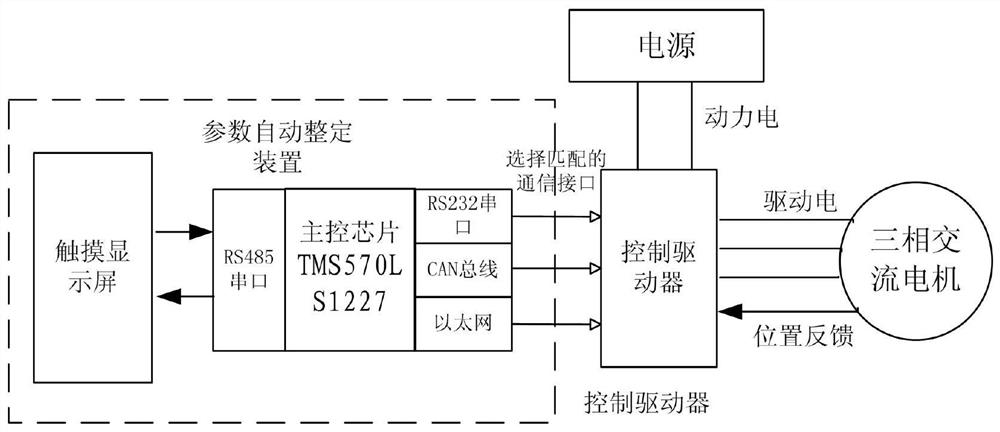

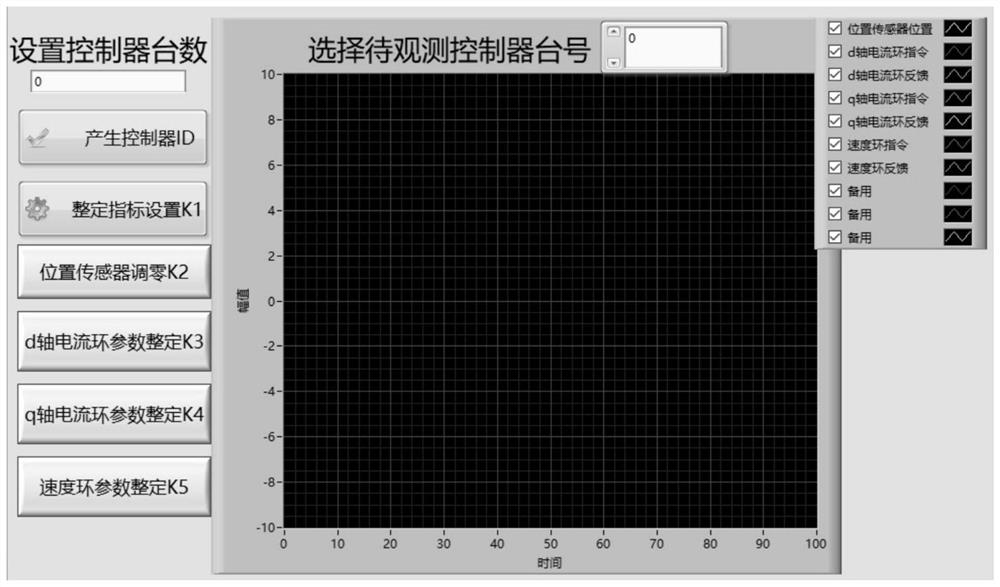

[0038] Such as figure 2 As shown, a specific embodiment of a permanent magnet synchronous motor control parameter self-tuning device, including a main control chip TMS570LS1227, an RS232 serial communication module, a CAN communication module, an Ethernet communication module and a touch screen. RS232 serial communication module, CAN communication module and Ethernet communication module are integrated inside the setting device, and the touch screen is integrated outside the setting device.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com