Structure for preventing warping of single carrier

A carrier and warping technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of large laser measurement deviation, increased risk factor, and damage to equipment spare parts, so as to reduce the heating area and reduce the probability of scrapping , The effect of reducing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

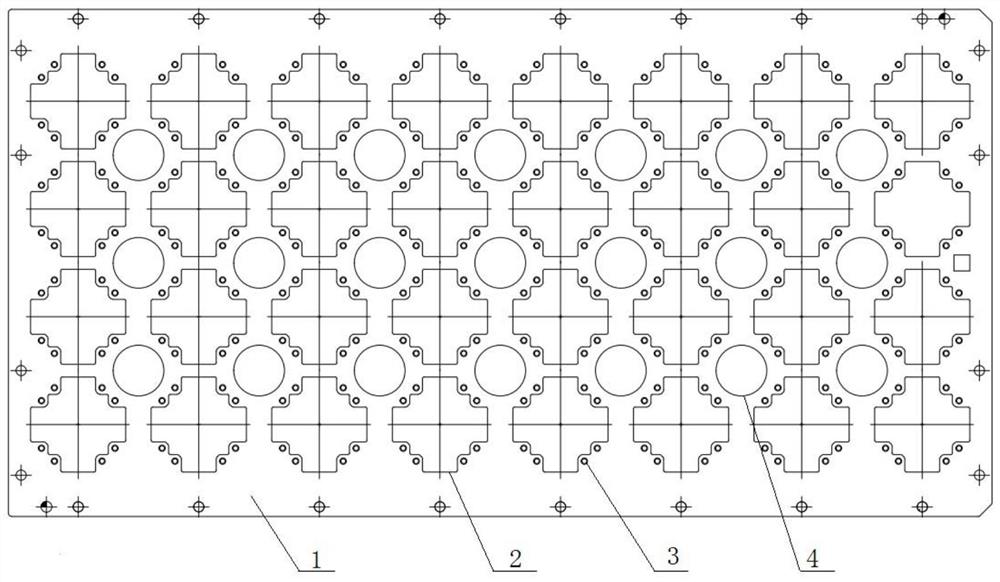

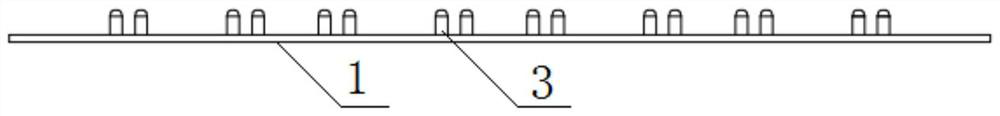

[0044] The carrier body 1 is provided with a number of product positioning holes 2 and stress release holes 4. The product is placed on the carrier body 1 through the product positioning holes 2, and the stress release holes 4 are scattered and distributed on the carrier body 1. The stress release holes 4 is a circular structure. When the carrier body 1 is in a high temperature process, the heat is dissipated through a number of circular stress release holes, which reduces the heated area of the carrier body 1 and reduces the warpage of the carrier body 1 .

Embodiment 2

[0046]The carrier body 1 is provided with a number of product positioning holes 2 and stress release holes 4. The product is placed on the carrier body 1 through the product positioning holes 2, and the stress release holes 4 are scattered and distributed on the carrier body 1. The stress release holes 4 has a rectangular structure. When the carrier body 1 is in a high temperature process, heat is dissipated through a number of rectangular stress release holes, which reduces the heated area of the carrier body 1 and reduces the warpage of the carrier body 1 .

Embodiment 3

[0048] The carrier body 1 is provided with a number of product positioning holes 2 and stress release holes 4. The product is placed on the carrier body 1 through the product positioning holes 2, and the stress release holes 4 are scattered and distributed on the carrier body 1. The stress release holes 4 has a triangular structure. When the carrier body 1 is in a high temperature process, heat is dissipated through a number of triangular stress release holes, which reduces the heated area of the carrier body 1 and reduces the warpage of the carrier body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com