Continuous synthesis method of 2-acetamido-5-nitroanisole

A technology for nitroanisole and o-anisole is applied in the field of continuous synthesis of 2-acetamido-5-nitroanisole, and can solve the problems of low product purity, poor product quality, low safety, and the like, To achieve the effect of improving the reaction rate, reducing the cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of 2-acetamido-5-nitroanisole continuous synthetic method, carries out following steps successively:

[0038] (1) Pre-acylation: add 9000 g of acetic acid mixture with a mass fraction of 15% anthranil to the reaction kettle, and react at a temperature of 20°C for 1 hour;

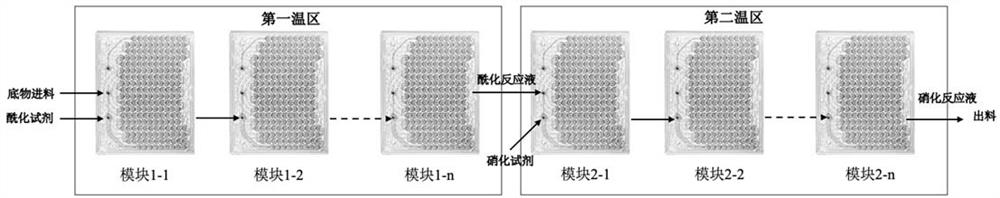

[0039] (2) Amidation: Pump the acetic acid mixture reaction liquid and 859g acetic anhydride (8.8mol) into the first temperature zone of the microchannel reactor at the same time, mix and complete the amidation reaction; the first temperature zone is set 1 reaction module, the amidation temperature is 20°C, the residence time is 0.5min, and the amidation reaction solution is obtained;

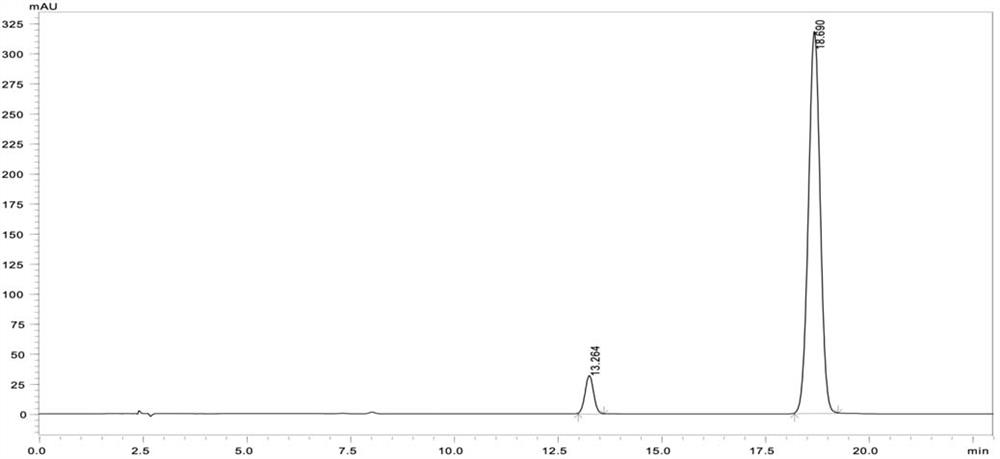

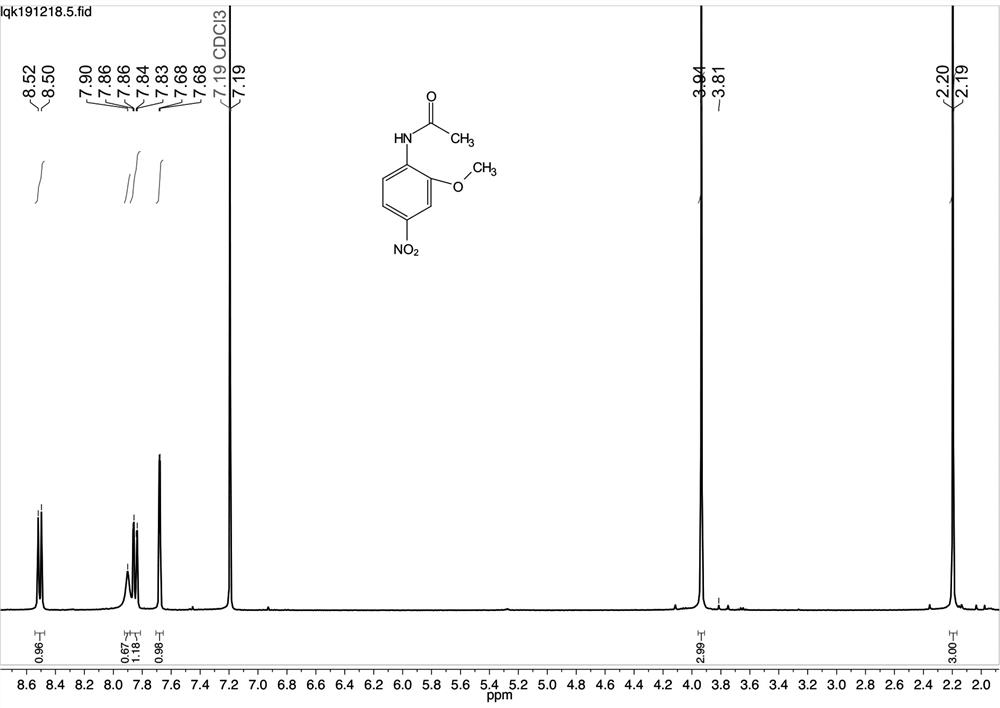

[0040] (3) Nitration: Continue to flow the amidation reaction solution in step (2) to the second temperature zone of the microchannel reactor, and at the same time pump 728.5g 98% nitric acid (11.35mol) into the second temperature zone, mix and complete the nitration reaction, The second temperature zone is equ...

Embodiment 2

[0044] A kind of 2-acetamido-5-nitroanisole continuous synthetic method, carries out following steps successively:

[0045] (1) Pre-acylation: Add 9,000 g of acetic acid mixture with a mass fraction of 25% anthranil to the reactor, and heat up to 35°C for 5 hours;

[0046](2) Amidation: Pump the acetic acid mixture reaction liquid and 186.7g acetic anhydride (1.83mol) into the first temperature zone of the microchannel reactor at the same time, mix and complete the amidation reaction; the first temperature zone Set up 4 reaction modules, the amidation temperature is 35°C, the residence time is 2.0min, and the amidation reaction solution is obtained;

[0047] (3) Nitration: Continue to flow the amidation reaction solution in step (2) to the second temperature zone of the microchannel reactor, and pump 1529.4g 98% nitric acid (23.79mol) into the second temperature zone at the same time, mix and complete the nitration reaction, Set up 6 reaction modules in the second temperature...

Embodiment 3

[0051] A kind of 2-acetamido-5-nitroanisole continuous synthetic method, carries out following steps successively:

[0052] (1) Pre-acylation: Add 9,000 g of acetic acid mixture with a mass fraction of 20% anthranil to the reactor, and heat up to 30°C for 3 hours;

[0053] (2) Amidation: Pump the acetic acid mixture reaction liquid and 744.6g acetic anhydride (7.3mol) into the first temperature zone of the microchannel reactor at the same time, mix and complete the amidation reaction, the first temperature zone Set up 3 reaction modules, the amidation temperature is 30°C, and the residence time is 1.5min;

[0054] (3) Nitration: Continue to flow the amidation reaction solution in step (2) to the second temperature zone of the microchannel reactor, and at the same time pump 1126.3g 98% nitric acid (17.52mol) into the second temperature zone, mix and complete the nitration reaction, The second temperature zone is equipped with 4 reaction modules, the reaction temperature is 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com