Method for promoting start-up of anaerobic reactor based on conductive nano-material

An anaerobic reactor, conductive nanotechnology, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of long start-up time, short action time, secondary pollution, etc., to improve organic load tolerance, prevent sludge loss, Effect of increasing methane yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Present embodiment 1 is the anaerobic reactor for inoculating the anaerobic activated sludge containing conductive nano-ferric oxide, specifically:

[0049] A method for promoting anaerobic reactor startup based on conductive nanomaterials, said method utilizing conductive nanomaterials to promote anaerobic reactor startup, comprising the following steps:

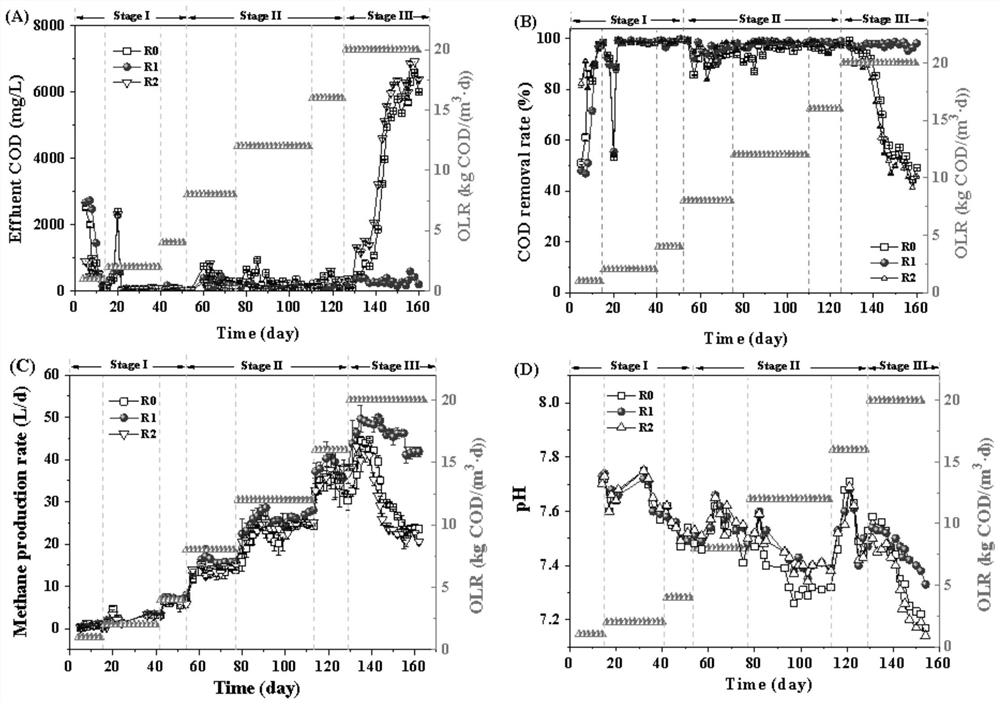

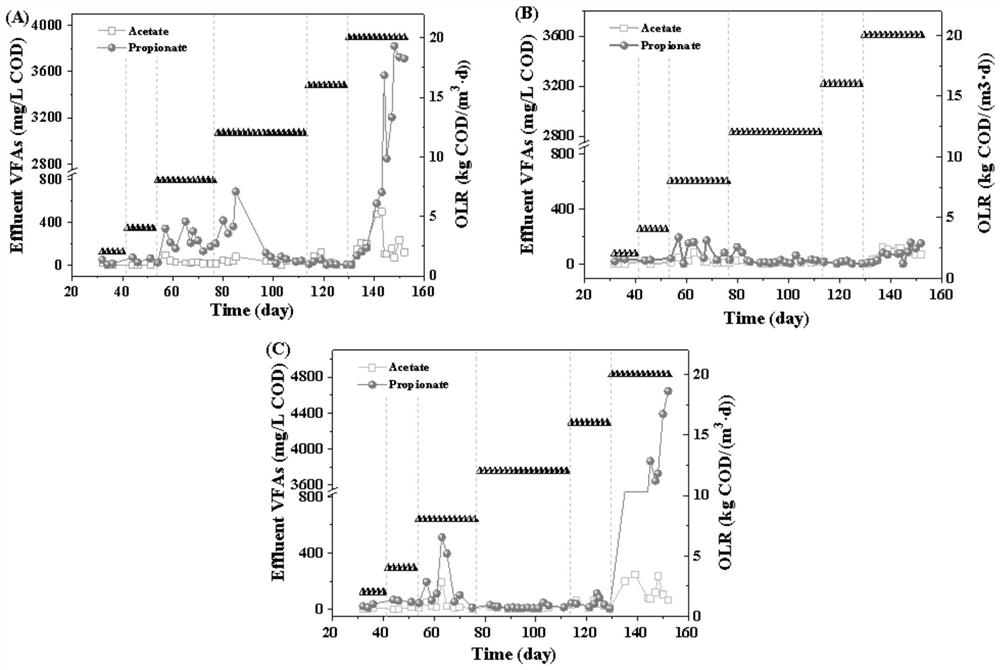

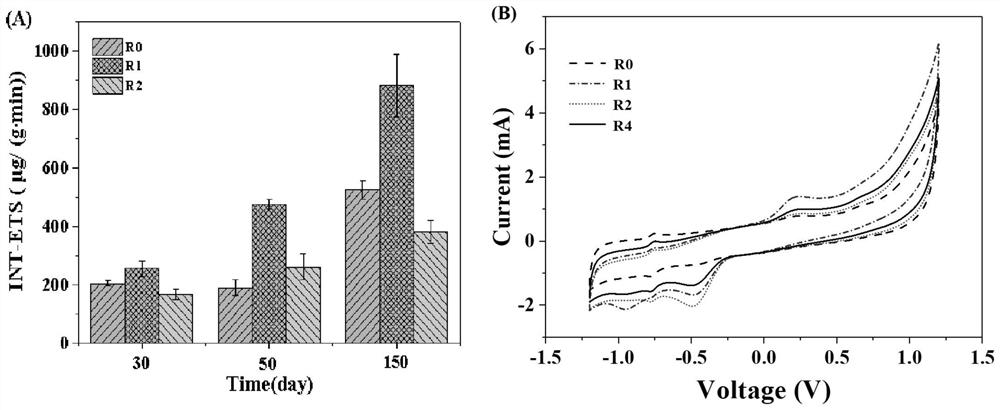

[0050] Prepare conductive nanomaterial composite anaerobic activated sludge, and the prepared conductive nanomaterial composite anaerobic activated sludge is inoculated to EGSB anaerobic reactor with the volume concentration of 12gVSS / L, and EGSB anaerobic reactor is started; When the EDSB anaerobic reactor is started, the pH is controlled to be 6.7-7.5, and the temperature is 35°C; during the start-up and operation of the EGSB anaerobic reactor, the COD:N:P is 200:5:1;

[0051] Wherein, the preparation method of the conductive nanomaterial composite anaerobic activated sludge is:

[0052] Add the conductive nanomat...

Embodiment 2

[0055] Present embodiment 2 is the anaerobic reactor that inoculates the anaerobic activated sludge that contains conductive nano ferric oxide, specifically:

[0056] A method for promoting anaerobic reactor startup based on conductive nanomaterials, said method utilizing conductive nanomaterials to promote anaerobic reactor startup, comprising the following steps:

[0057] Prepare conductive nanomaterial composite anaerobic activated sludge, and the prepared conductive nanomaterial composite anaerobic activated sludge is inoculated into EGSB anaerobic reactor with a volume concentration of 5gVSS / L, and EGSB anaerobic reactor is started; When the EDSB anaerobic reactor is started, the pH is controlled to be 6.7-7.5, and the temperature is 27°C; during the start-up and operation of the EGSB anaerobic reactor, the COD:N:P is 400:8:1;

[0058] Wherein, the preparation method of the conductive nanomaterial composite anaerobic activated sludge is:

[0059] Add the conductive nanom...

Embodiment 3

[0062] Present embodiment 3 is the anaerobic reactor that inoculates the anaerobic activated sludge containing conductive nano ferric oxide, specifically:

[0063] A method for promoting anaerobic reactor startup based on conductive nanomaterials, said method utilizing conductive nanomaterials to promote anaerobic reactor startup, comprising the following steps:

[0064] Prepare conductive nanomaterial composite anaerobic activated sludge, and the prepared conductive nanomaterial composite anaerobic activated sludge is inoculated to EGSB anaerobic reactor with the volume concentration of 18gVSS / L, and EGSB anaerobic reactor is started; When the EDSB anaerobic reactor is started, the pH is controlled to be 6.7-7.5, and the temperature is 36°C; during the start-up and operation of the EGSB anaerobic reactor, the COD:N:P is 300:2:1;

[0065] Wherein, the preparation method of the conductive nanomaterial composite anaerobic activated sludge is:

[0066] Add the conductive nanomat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com