Rapid stamping device for metal handicraft machining and method

A technology for stamping devices and handicrafts, applied in metal processing equipment, peeling devices, forming tools, etc., can solve the problems of poor control of lubricating oil smearing amount, poor lubrication effect, troublesome replacement of workpiece materials, etc. Influence, improve smear effect, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

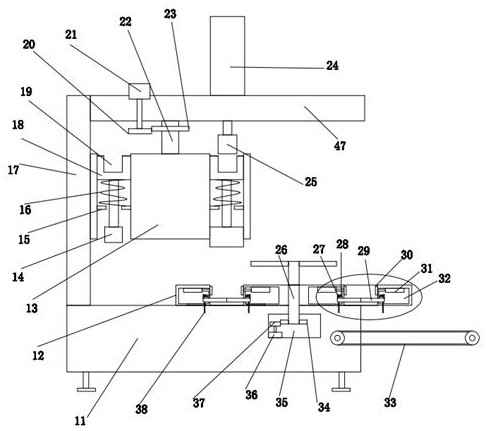

[0028] see Figure 1-6 , in an embodiment of the present invention, a quick stamping device for processing metal crafts, comprising a base 11 and several legs arranged at its lower end, the upper end of the base 11 is provided with an upper mold assembly for quick stamping of metal parts, The upper mold assembly includes a column 17 connected to the upper end of the base 11 and a mounting horizontal plate 47 arranged on the upper end of the column 17. The upper end of the mounting horizontal plate 47 is equipped with a lifting push rod 24, and the output end of the lifting push rod 24 There is a docking block 25, and the mounting horizontal plate 47 is provided with stamping parts that cooperate with the docking block 25 and are used to switch punching heads;

[0029] The upper end of the base 11 is provided with a lower mold assembly matched with the upper mold assembly, the lower mold assembly includes a clamping seat 12, and two sides of the upper end of the clamping seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com