Single crystal manufacturing device

A single crystal manufacturing device and single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as failure to become a product, single crystal 104 slip dislocation, single crystal 104 separation, etc., to achieve growth The effect of increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] In Example 1, the following conditions are used. figure 1 The single crystal manufacturing apparatus 1 performs a growth of single crystal 4 and verifies the crystalline drawing speed of single crystal 4 capable of obtaining the desired quality.

[0088] The growth of single crystal 4 is single crystal silicon, and a silicon crystal having a diameter of 12 inches (300 mm) is produced by applying a magnetic field chroskichiometry (MCZ method). Quartz crucible 6 has a diameter of 32 inches (800 mm). The inner diameter of the cooling cylinder 12 is 430 mm, and the design value of the outer diameter of the cooling the auxiliary tube 19 is 429.5 mm, and its length is 350 mm. The tolerances of the outer diameter of the cooling cylinder 12 and the outer diameter of the cooling the auxiliary tube 19 are ± 0.4 mm, ± 0.1 mm, respectively.

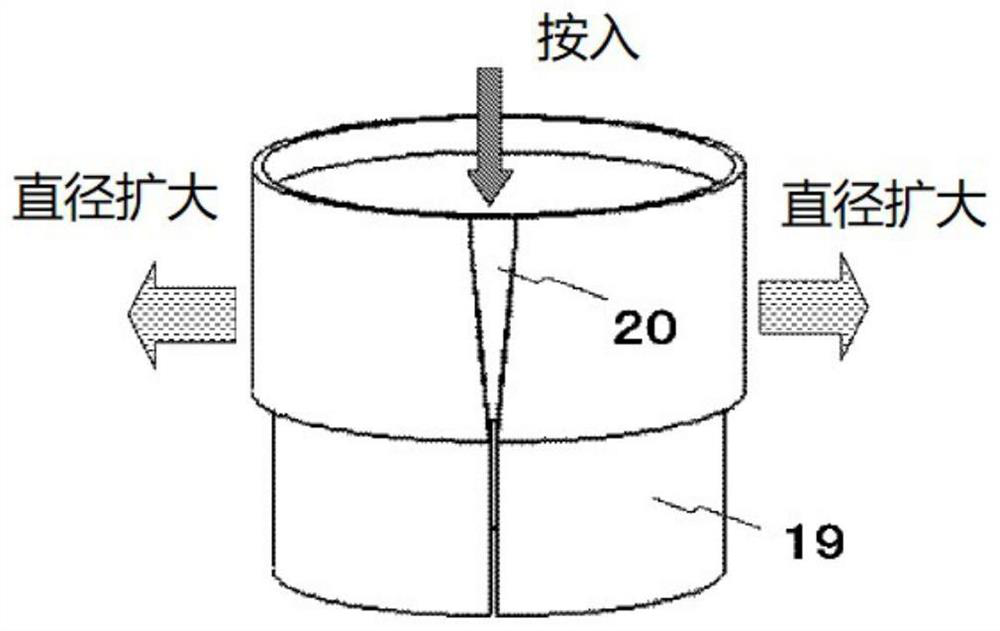

[0089] like figure 2 As shown, the components having a cracked SL through which are penetrated along the axial direction, and the upper portion o...

Embodiment 2

[0106] In Example 2, the following conditions are used. Figure 4 The single crystal manufacturing apparatus 1 'performs the growth of single crystal 4 and verifies the crystalline drawing speed of single crystal 4 capable of obtaining the desired quality.

[0107] The growth of single crystal 4 is single crystal silicon, except for use Figure 5 The cooling auxiliary cylinder 19 and the diameter enlargement member 20 were produced in the same conditions as in Example 1, and the same evaluation as in Example 1 was carried out. That is, the design value of the inner diameter of the cooling cylinder 12 is 430 mm, and the design value of the outer diameter of the cooling the auxiliary tube 19 is 429.5 mm, and the length is 350 mm. Further, the tolerance of the outer diameter of the cooling cylinder 12 and the outer diameter of the cooling the auxiliary tube 19 is ± 0.4 mm, ± 0.1 mm, respectively.

[0108] like Image 6 As shown, four cracks S1 through which are penetrated along the axia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com