Method for producing non-oriented electrical steel coated semi-process products

A technology of grain-oriented electrical steel and production method, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of large iron core eddy current loss, increase equipment investment, etc., to improve electromagnetic performance, increase product energy storage, grain size The effect of increased growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

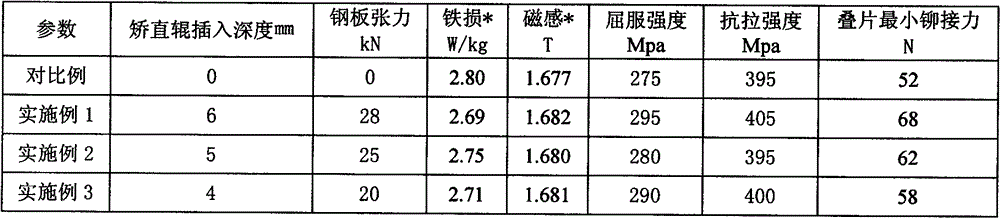

[0008] The present invention will be further described below by way of examples.

[0009] The weight percent of the chemical composition of the electrical steel in the embodiment of the present invention is: C: 0.002%, Si: 2.35%, Mn: 0.27%, P: 0.015%, S: 0.003%, Als: 0.24%, the rest is iron and unavoidable impurity elements.

[0010] The production method of the embodiment of the present invention comprises the following process steps:

[0011] a) Smelting: use converter smelting, RH vacuum refining treatment, the composition of molten steel is controlled according to the above requirements, and continuous casting into billets;

[0012] b) Hot rolling and normalizing treatment: heating the steel billet to 1100°C, starting rolling temperature at 1020°C, finishing rolling temperature at 860°C, coiling temperature at 650°C, and hot rolled sheet normalizing temperature at 920°C;

[0013] c) Annealing of cold-rolled finished products: the steel plate is continuously annealed at 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com