A planetary workpiece holder of a vacuum coating machine

A vacuum coating machine and workpiece rack technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve problems such as poor adaptability, environmental pollution, difficult to cure, etc., achieve fast loading and unloading, and improve coating Accumulation speed, effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

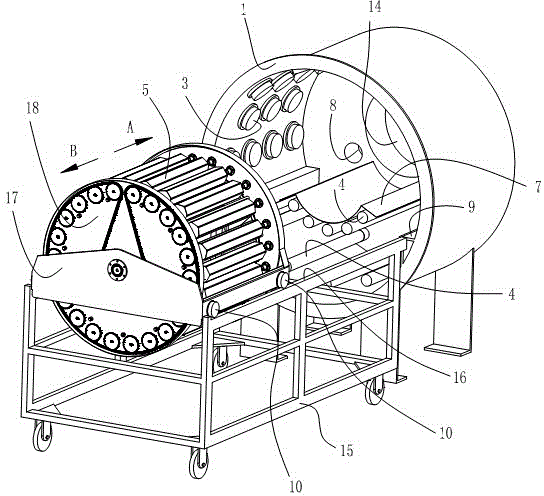

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

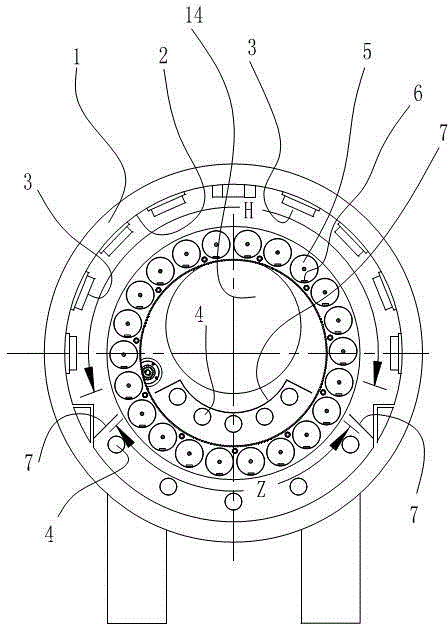

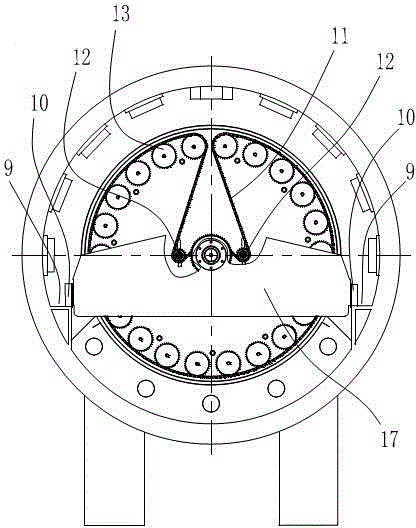

[0027] Such as Figure 1A As shown, the vacuum coating machine has a planetary workpiece rack, and the rotating cage 5 in the planetary workpiece rack is arranged between the arc target 3 and the sputtering target 4 .

[0028] The rotating cage 5 revolves around the K direction or the opposite direction of K. When the rotating cage 5 revolves to the H area, the workpiece 6 is efficiently arc-plated under the action of multiple arc targets; when the rotating cage 5 revolves to the Z area, the workpiece 6 Efficient sputter plating is performed under the action of a plurality of sputter targets.

[0029] The arc target and sputtering target shielding baffle 7 effectively separates the arc plating H area and the sputter plating Z area, ensures that the two coating process areas do not interfere with each other, effectively prevents mutual pollution between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com