Control method and device of fabric defect detection system

A defect detection and control method technology, applied in the field of visual inspection, can solve problems such as inapplicable fabric defect detection, and achieve the effect of improving image acquisition quality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

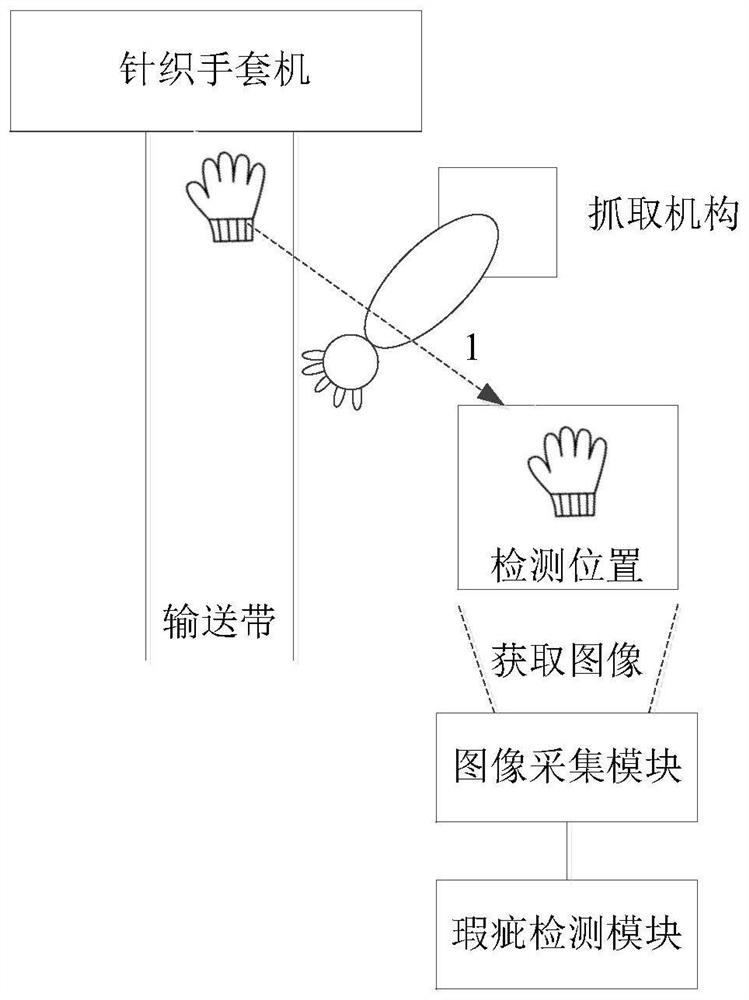

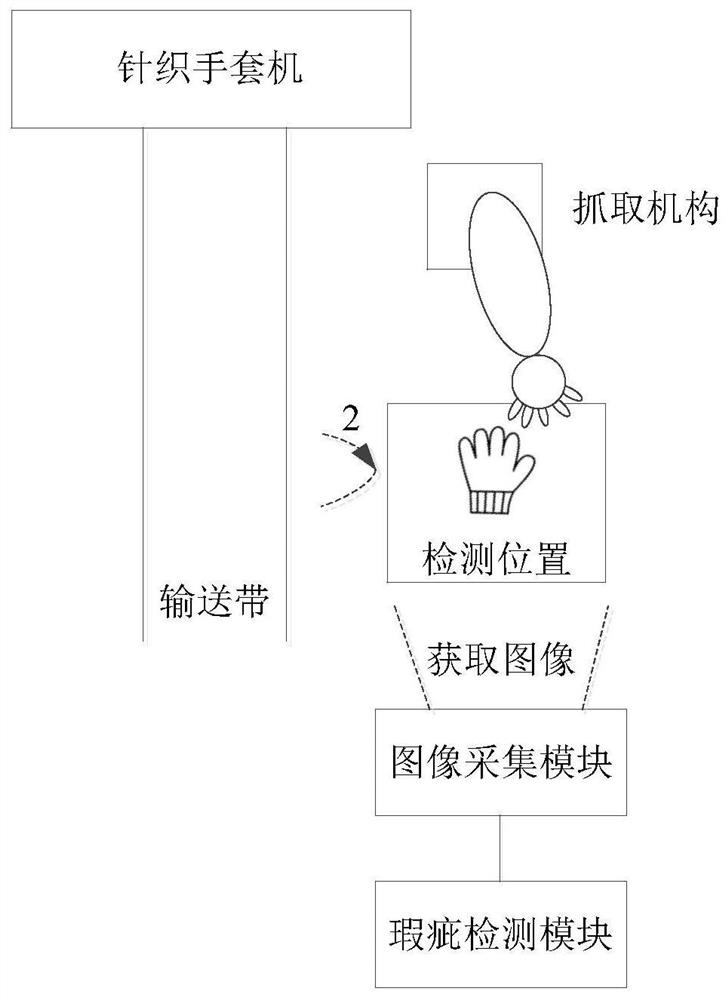

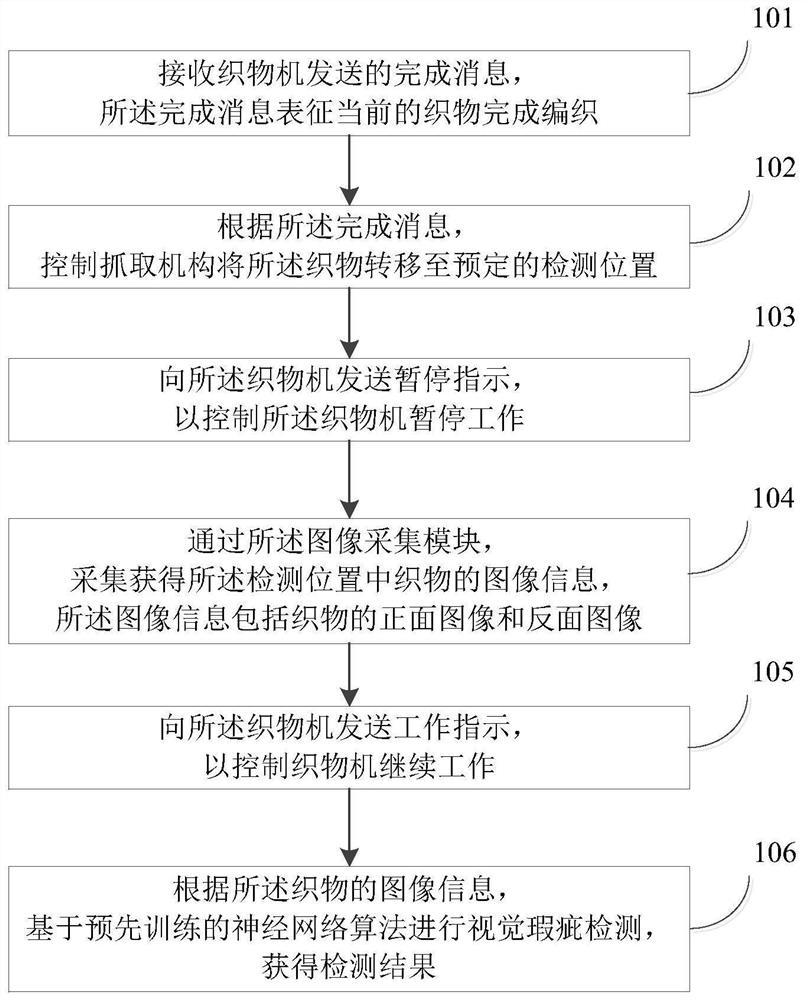

[0037] The control method of the fabric defect detection system provided by this application can be applied to Figure 1a to Figure 1b An application scenario is shown. The fabric can be gloves, socks, or knitted products such as handkerchiefs and scarves. Take the defect detection process of a knitting glove machine as an example, such as Figure 1a to Figure 1b As shown, the flaw detection system for knitted gloves includes: an image acquisition module, a grabbing mechanism, a knitted glove machine, and a flaw detection module. Such as Figure 1a As shown, the knitting glove machine knits a glove, transmits it on the conveyor belt, and suspends knitting; the grabbing mechanism transfers the glove to be detected to the detection position (shown by arrow 1 in the figure), and the image acquisition module acquires the knit glove The positive image of , and retain the image information. Next, if Figure 1b As shown, the grabbing mechanism turns over the glove to be detected (...

Embodiment 2

[0068] A schematic structural diagram of the control device of the fabric defect detection system provided in Embodiment 2 of the present application, as shown in Figure 7 As shown, the fabric defect detection system includes a fabric machine 10 , a gripping mechanism 20 , an image acquisition module 30 , and a defect detection module 40 . The control device of the fabric defect detection system includes an acquisition module 50 and a processing module 60 . An operator can control the plant defect detection system through the control device.

[0069] Wherein, the weaving machine 10 is a device with a knitting function, specifically a glove knitting machine and a hosiery machine. Grabbing mechanism 20 is a mechanism with the position transfer of articles, specifically, it can be a manipulator with grabbing ability, a grabbing clip; There are many loops on the surface; one side is a hook surface, there are many uniform small hooks on the surface, and the hook structure can ad...

Embodiment 3

[0088] Figure 9 A schematic structural diagram of an electronic device provided in Embodiment 3 of the present application, such as Figure 9 As shown, the electronic equipment includes:

[0089] A processor (processor) 291 , the electronic device also includes a memory (memory) 292 ; it may also include a communication interface (Communication Interface) 293 and a bus 294 . Among them, the processor 291 , the memory 292 , and the communication interface 293 can communicate with each other through the bus 294 . The communication interface 293 can be used for information transmission. The processor 291 can invoke logic instructions in the memory 292 to execute the methods of the above-mentioned embodiments.

[0090] In addition, the above-mentioned logic instructions in the memory 292 may be implemented in the form of software function units and may be stored in a computer-readable storage medium when sold or used as an independent product.

[0091] The memory 292, as a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com