Urea solution double-nozzle aftertreatment device and control method thereof

A technology of post-processing device and urea nozzle, which is applied in the direction of electric control of exhaust treatment device, diagnostic device of exhaust treatment device, exhaust device, etc. It can solve the problem of turbocharger surge output torque, limited heating effect, oil Dilution and other issues, to achieve the effect of reducing throttle surge, reducing the difficulty of heating up, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

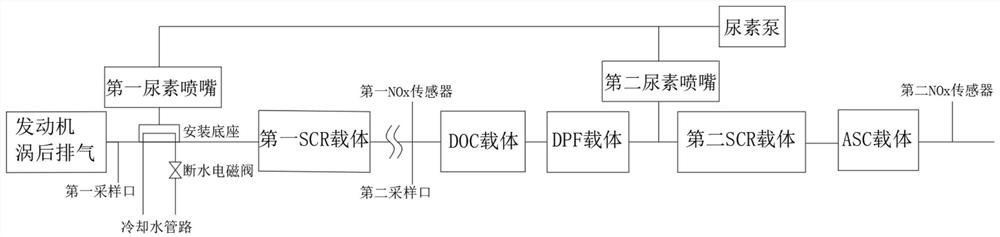

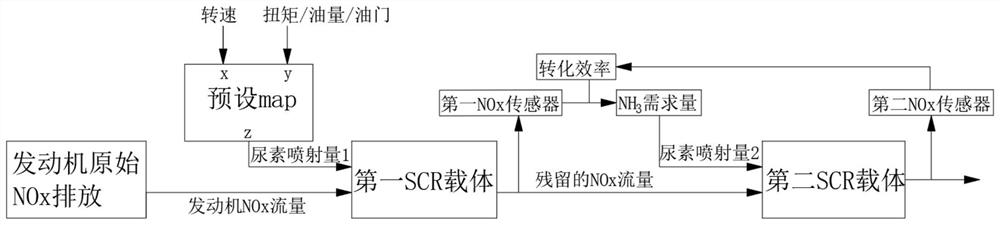

[0046] Such as figure 1As shown, a urea solution dual-nozzle aftertreatment device includes a first urea nozzle 1 and a second urea nozzle 2, the first urea nozzle 1 is arranged behind the engine vortex, and the rear end of the first urea nozzle 1 is sequentially The first SCR carrier 3, the DOC carrier 4, the DPF carrier 5, the second SCR carrier 6 and the ASC carrier 7 are connected, the second urea nozzle 2 is arranged between the DPF carrier 5 and the second SCR carrier 6, and the second The second urea nozzle 2 is connected with the first urea nozzle 1 and is connected with a urea pump 8 .

[0047] A first NO is arranged between the rear end of the first SCR carrier 3 and the front end of the DOC carrier 4 X The sensor 9 and the second sampling port 10 , a first sampling port 11 is arranged between the engine vortex and the first urea nozzle 1 .

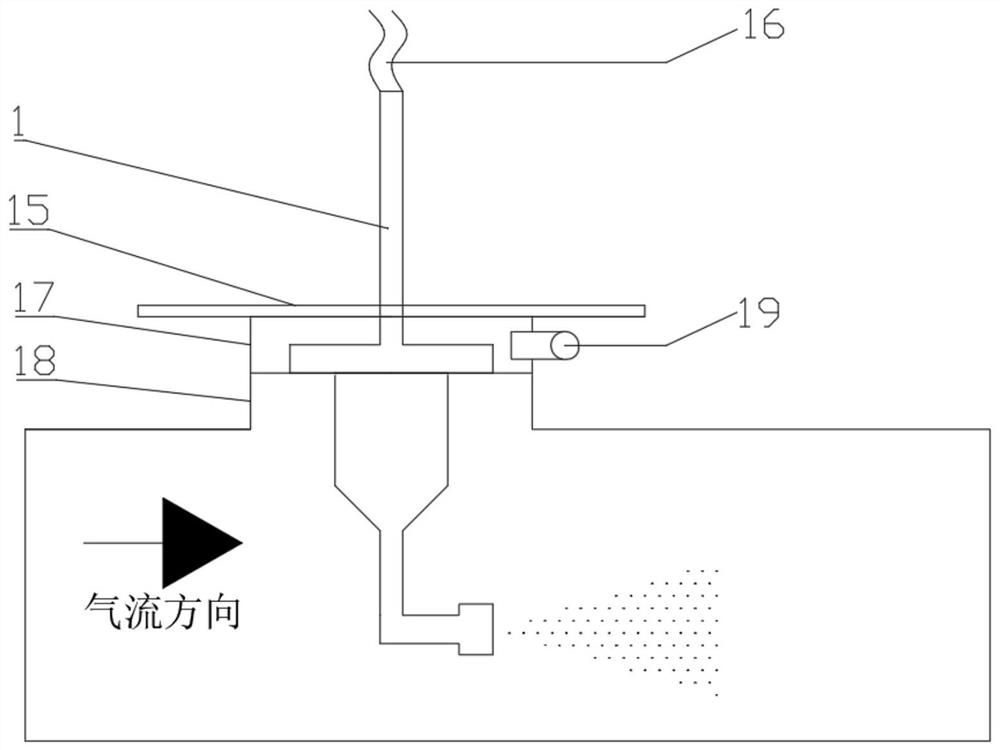

[0048] The installation position of the first urea nozzle 1 and the first SCR carrier 3 is close to the engine vortex, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com