Low-emission and high-power-performance starting control method of diesel engine vehicle

A control method, diesel engine technology, applied in engine control, electrical control, fuel injection control, etc., can solve problems such as air volume reduction, engine maximum torque reduction, and failure to meet emission regulations, etc., to achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A low-emission and high-dynamic starting control method for a diesel engine vehicle, the diesel engine vehicle has an exhaust gas recirculation system EGR, and the EGR has two levels of exhaust gas circulation volume, that is, the starting exhaust gas circulation volume and the driving exhaust gas circulation volume;

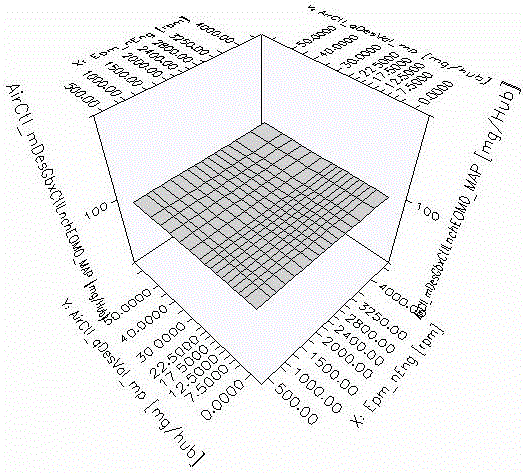

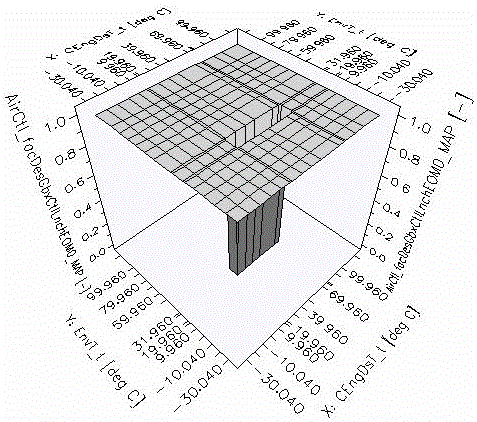

[0018] The exhaust gas circulation volume of the exhaust gas recirculation system EGR is determined by the function of engine speed and fuel injection quantity multiplied by a coefficient, which is related to the engine cooling water temperature and ambient temperature; figure 1 , 2 As shown, after the relevant map is obtained through the test, the coefficient is selected according to the needs of power and emission;

[0019] In the present invention, first set a starting time, in this embodiment, this time is set to 2 seconds, and carry out the following control according to the signal sent by the transmission controller TCU, to select the gear of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com