Water-borne aluminum foil working fluid

A processing fluid and aluminum foil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor sheet falling, poor quality of heat exchangers, and increased discharge and treatment of cleaning waste liquid, so as to increase VOC emissions and improve lubrication Performance, the effect of improving the antirust ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation steps of the water-based aluminum foil stamping processing fluid of the present invention are as follows:

[0026] According to embodiment 1, embodiment 2, embodiment 3, embodiment 4, add water, alkanolamide, alcohol amine, polyethylene glycol type nonionic surfactant, defoamer respectively in container, stir to a clear or translucent stable liquid.

[0027] The water-based processing fluid of the present invention is compared with the existing volatile lubricating oil used for aluminum fin heat exchanger processing, and the evaluation method adopted is as follows:

[0028] Maximum non-jamming load: GB / T 3142-1982 Determination of bearing capacity of lubricants.

[0029] Corrosion test: GB / T 5096-1985 Copper Corrosion Test Method for Petroleum Products.

[0030] SH / T 0195-1992 Lubricating Oil Corrosion Test Method.

[0031] GB 11143-1989 Anti-rust performance test method of mineral oil with inhibitor in the presence of water

[0032] Dryness: Spread ...

Embodiment 1

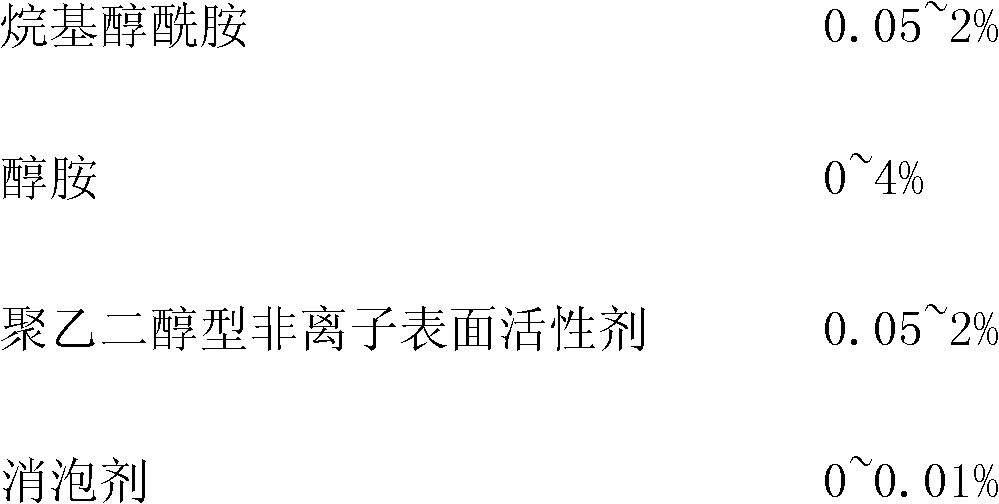

[0035]

[0036]

Embodiment 2

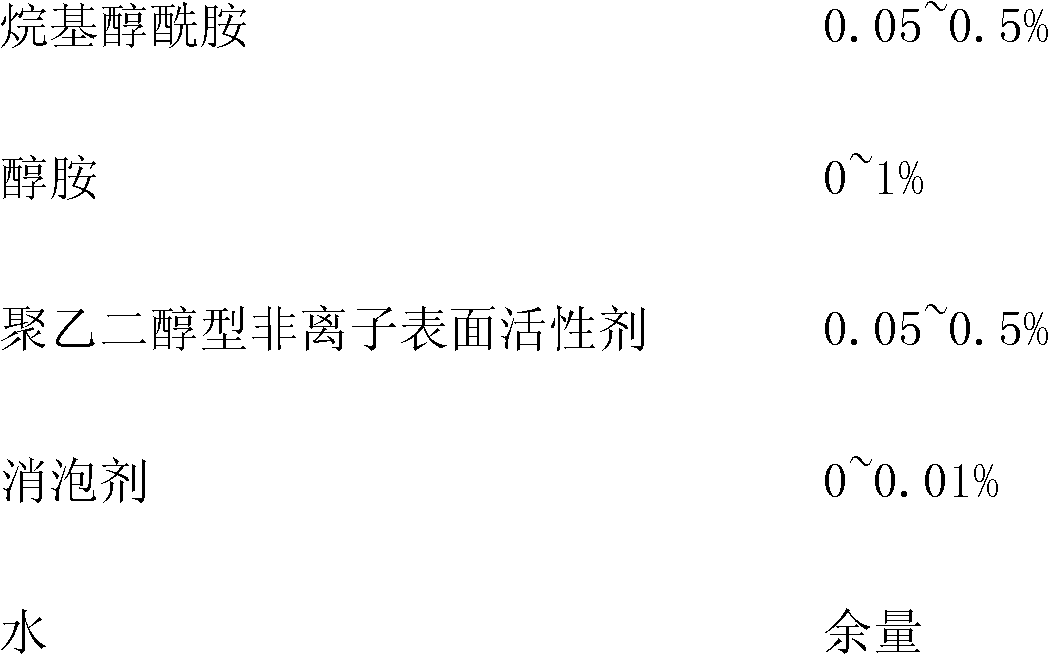

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com