Composition containing polypropylene copolymer, polypropylene copolymer material, and preparation method and application of polypropylene copolymer material

A polypropylene copolymer and composition technology, applied in the field of polyolefin materials, can solve the problem of unsatisfactory adhesion effect of ink and adhesive, difficult diffusion of ink or adhesive molecules, poor gloss and transparency and other problems, to achieve the effect of low melting temperature, low crystallinity and good hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

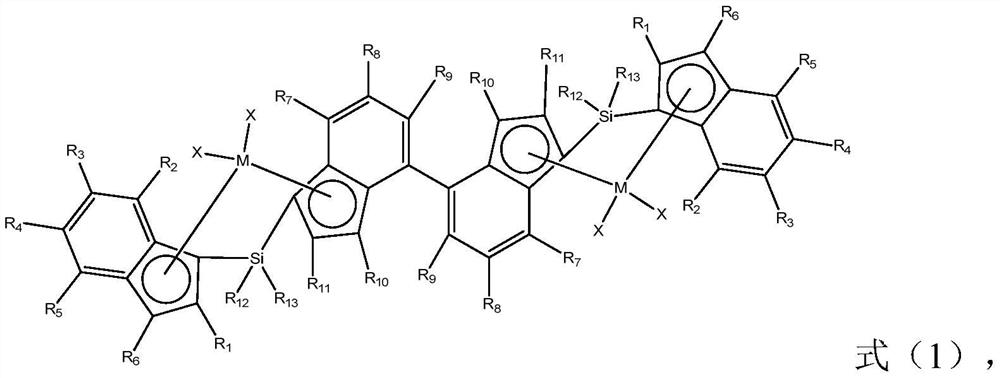

[0043] In formula (1), the two Ms are the same and are Ti, Zr or Hf;

[0044] each X is the same and is fluorine, chlorine or bromine;

[0045] R 1 , R 2 , R 3 , R 4 , R 7 , R 8 , R 9 and R 11 Each independently is H, substituted or unsubstituted C 1 -C 4 Alkyl, substituted or unsubstituted C 2 -C 4 Alkenyl, substituted or unsubstituted C 7 -C 20 Aralkyl, substituted or unsubstituted C 6 -C 20 Aryl;

[0046] R 1 , R 2 , R 3 , R 4 , R 7 , R 8 , R 9 and R 11 The optional substituents in each independently selected from C 1 -C 4 at least one of the alkyl groups of

[0047] R 12 and R 13 each independently is H, methyl or ethyl;

[0048] R 5 is phenyl; and

[0049] R 6 and R 10 Both are hydrogen.

specific Embodiment approach 2

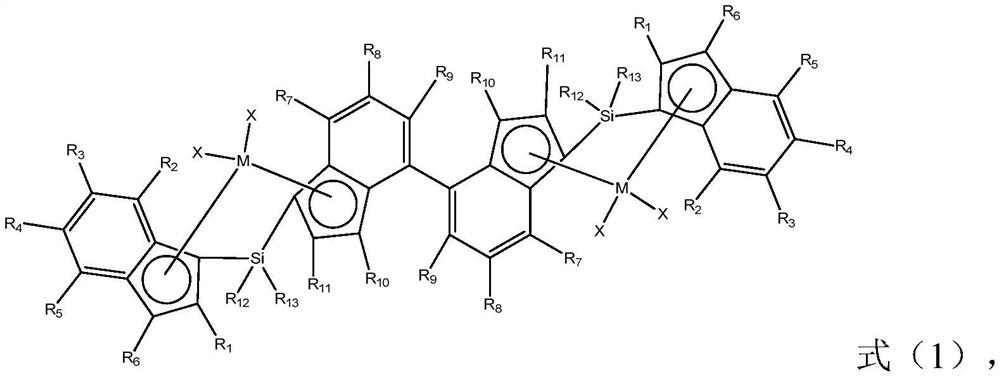

[0050] In formula (1), the two Ms are the same and are Ti, Zr or Hf;

[0051] each X is the same and is chlorine;

[0052] R 1 and R 11 Both are methyl;

[0053] R 2 , R 3 , R 4 , R 6 , R 7 , R 8 , R 9 and R 10 Both are H;

[0054] R 5 is phenyl; and

[0055] R 12 and R 13 Each is independently H, methyl or ethyl.

specific Embodiment approach 3

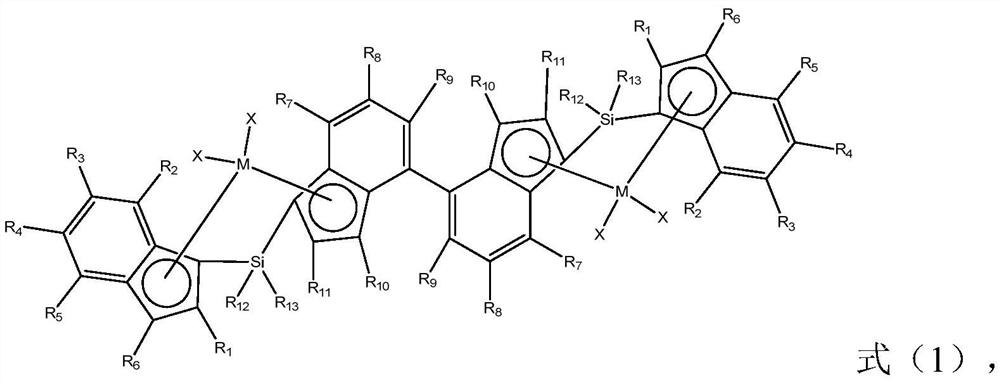

[0056] In formula (1), the two Ms are the same and are Ti, Zr or Hf;

[0057] each X is the same and is chlorine;

[0058] R 1 and R 11 Both are methyl;

[0059] R 2 , R 3 , R 4 , R 6 , R 7 , R 8 , R 9 and R 10 Both are H;

[0060] R 5 is phenyl; and

[0061] R 12 and R 13 Both are methyl.

[0062] Preferably, in the polypropylene copolymer, the content weight ratio of the structural unit A to the structural unit B is 100:(0.5-5); more preferably, in the polypropylene copolymer, the structure The content weight ratio of unit A and structural unit B is 100:(1.5-3).

[0063] In order to achieve better effects of low crystallinity and low melting point of the copolymer, preferably, the polypropylene copolymer has 2,1-insertion. This 2,1-insertion can be detected by NMR.

[0064] Preferably, the melting temperature of the polypropylene copolymer is less than or equal to 147°C, more preferably, the melting temperature of the polypropylene copolymer is less than o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com