Preparation method of nanometer titanium dioxide artificial antibody shell for identifying and degrading chlorpyrifos

A nano-titanium dioxide, artificial antibody technology, applied in the field of material science, can solve problems such as cumbersome steps and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

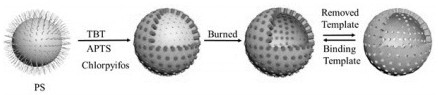

[0051] Specific embodiments: a method for preparing a nano-titanium dioxide artificial antibody shell for chlorpyrifos recognition and degradation, characterized in that: the chlorpyrifos imprinted molecules located in the shell are eluted from the nano-titanium dioxide artificial antibody shell, and the shell The internal structure of the imprinted molecules has a complementary cavity structure, size and functional groups, and the microspheres that elute the imprinted molecules have specific recognition sites for the target analyte molecules to achieve specific recognition and degradation of the target analyte molecules , the preparation process of the nano-titanium dioxide artificial antibody shell comprises the following steps:

[0052]Preparation of nano-titanium dioxide artificial antibody shell: Measure 4~6mL of the prepared polystyrene microspheres rich in carboxyl groups on the surface and place them in a 100mL ground-mouth Erlenmeyer flask, then add 20~40mL ethanol, 2...

Embodiment

[0054] Example: Using polystyrene, 3-aminopropyltriethoxysilane and tetrabutyl titanate as raw materials, the nano-titanium dioxide artificial antibody shell can be obtained through reaction.

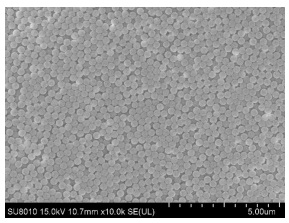

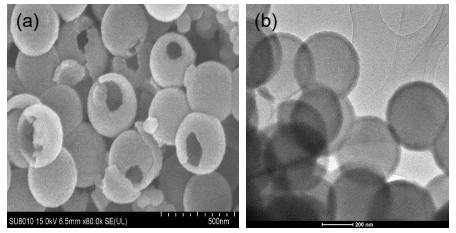

[0055] Preparation of nano-titanium dioxide artificial antibody shell: Measure 5 mL of polystyrene microspheres rich in carboxyl groups on the surface and place them in a 100 mL ground-mouth Erlenmeyer flask, then add 30 mL of ethanol, 15 mg of chlorpyrifos and 10 μL3 -Aminopropyltriethoxysilane was ultrasonically dispersed in the above solution, and then 20mL of 10% tetrabutyl titanate ethanol solution was slowly added, the surface was coated with sealing grease ground glass plug to seal, and the reaction was carried out at 500rpm for 1.5h. Then add 3mL of ammonia water to continue the reaction for 2h, then wash with absolute ethanol three times, heat up to 550°C for 2h in a muffle furnace at 5°C / min, and heat-preserve and calcinate for 2h. 1 in the methanol / acetic acid mixture solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com