A multifunctional carbon-coated aluminum foil automatic packaging machine

An automatic packaging machine, multi-functional technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of reduced efficiency of aluminum foil roll packaging, increased guarantee costs, etc., to achieve simple and reasonable structure, ensure integrity, reduce The effect of pocket size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

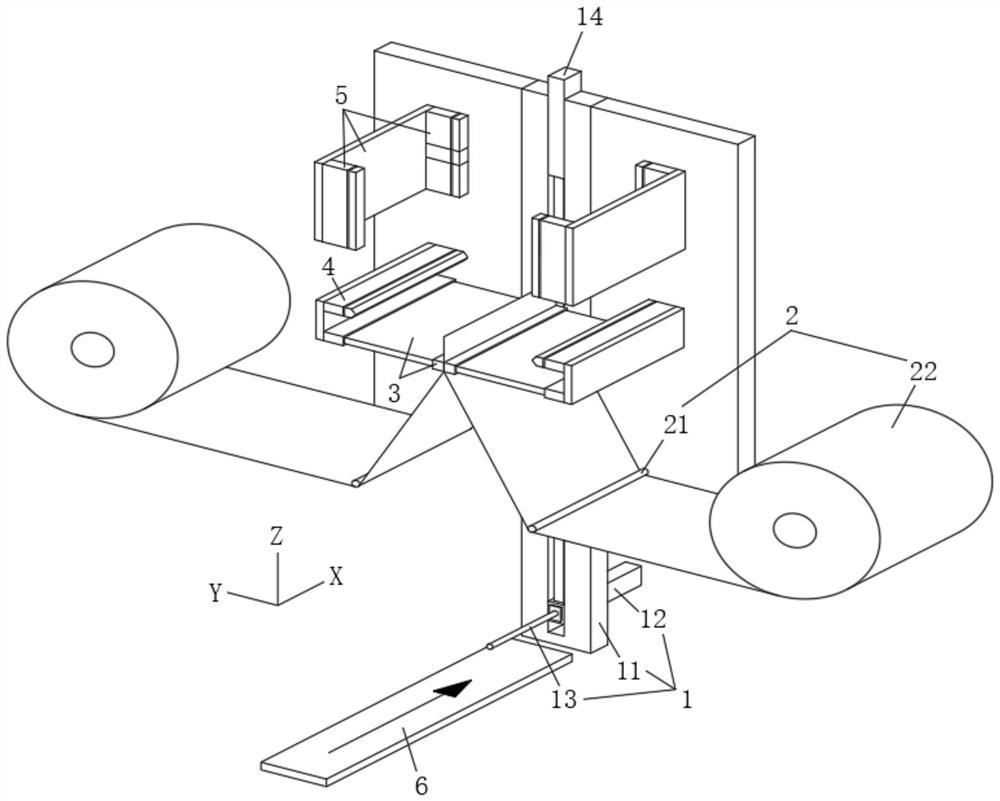

[0051] see Figure 6 As shown, in the embodiment of the present invention, a group of side packaging components 3 are provided, correspondingly in the present invention figure 1 In , it is also correspondingly expressed as the specific structure of this embodiment;

[0052] In this example:

[0053] A) When the fixed rod assembly 1 is at the lowest position, it corresponds to the loading position. At this time, the aluminum foil roll to be packaged is fixed manually or automatically, so that the central roll of the aluminum foil roll to be packaged is inserted in the On the fixed insertion rod 13;

[0054] B) Then, the mounting sleeve 12 is driven to rise in the first process along the lifting guide rail 11. During this process, the fixed rod assembly 1 and the aluminum foil roll to be packaged gradually approach the packaging film supply assembly 2, correspondingly expressed as Figure 6 a1 in the figure; it can be seen from the figure that at this time, the two first heat...

Embodiment 2

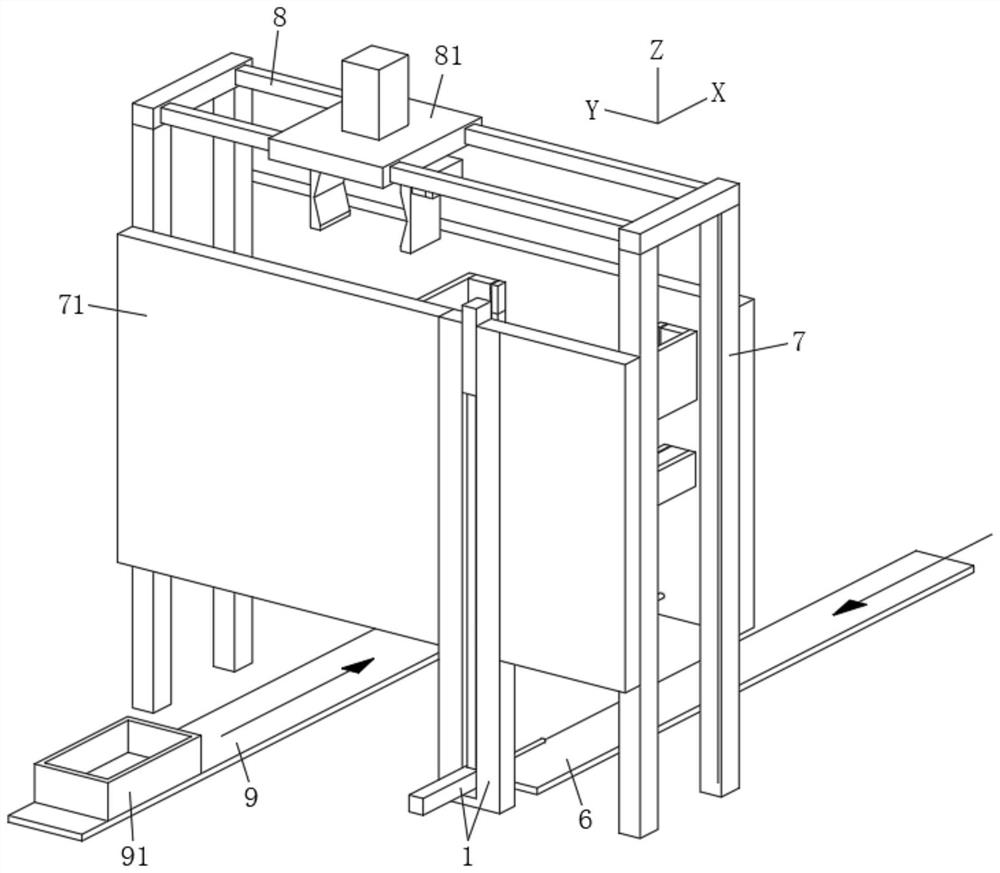

[0061] see Figure 7 As shown, in the embodiment of the present invention, there are two groups of side packaging components 3, and the film cutting component 4 is arranged between the two groups of side packaging components 3

[0062] In this example:

[0063] Step A), step B), and step C) are the same as the above-mentioned embodiment one, and the correspondence is expressed as Figure 7 a2 and b2 in

[0064] D) When the aluminum foil roll to be packaged exceeds two groups of side packaging components 3, start two groups of side packaging components 3 at the same time, so as to synchronously realize the second side sealing and the third side sealing in the first embodiment above; corresponding that is expressed as Figure 7 c2 in

[0065] E) Start the film cutting assembly 4, and cut the packaging film between the second side sealing position and the third side sealing position correspondingly, and the corresponding is expressed as Figure 7 c2 in

[0066] After cuttin...

specific Embodiment approach

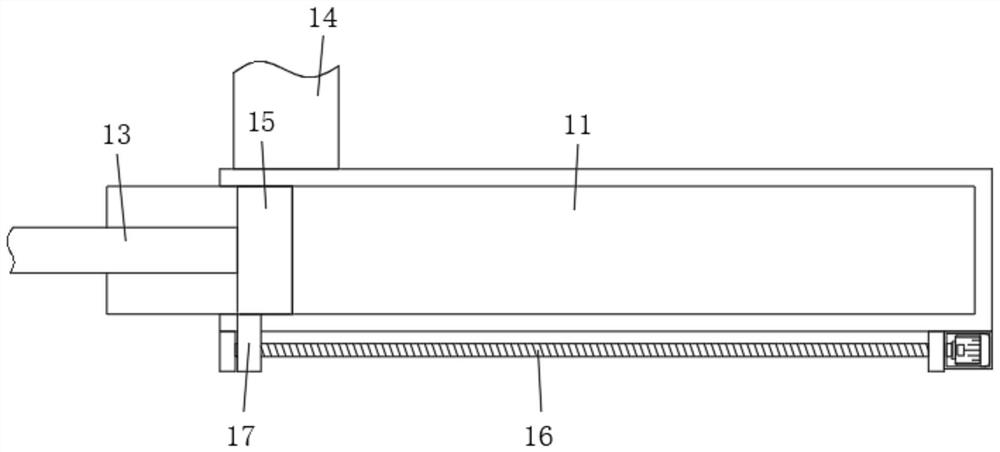

[0069] First, in order to realize the stable lifting of the mounting sleeve 12, a chute is provided in the middle of the Z-axis guide rail 11, and the mounting sleeve 12 is slidably fitted in the chute; the lifting cylinder 14 is fixed in the chute, and the lifting cylinder 14 is connected to the installation The cover 12 is connected to drive the installation cover 12 to reciprocate and lift along the chute.

[0070] Secondly, in order to further optimize the overall packaging, a vacuum pump 15 is provided in the mounting sleeve 12 of the fixed rod assembly 1, the fixed insertion rod 13 is a hollow rod, and the vacuum pump 15 is connected to the fixed insertion rod 13 to realize the aluminum foil roll to be packaged and packaged. Membrane vacuum encapsulation. Specifically, in this embodiment, when the fixed rod assembly 1 cooperates with the end sealing assembly 5 to perform the above-mentioned end sealing operation, the front end sealing assembly is first used to seal the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com