Manufacturing method of aluminum nitride substrate template

A production method, aluminum nitride technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting product growth efficiency, affecting AlN quality, uneven distribution of holes, etc., to improve photoelectric parameters and The effect of chip reliability, low cost and small internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

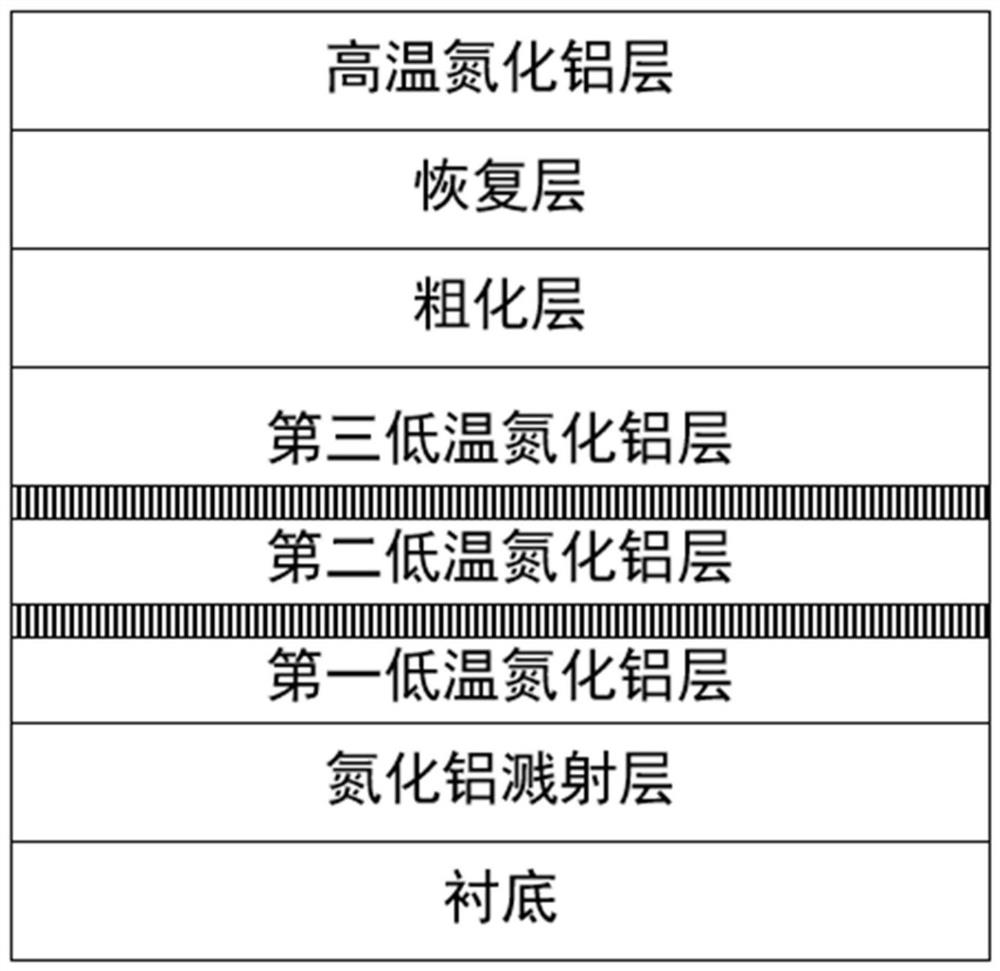

[0038] In order to overcome the problems existing in the prior art, the present invention proposes a method for manufacturing an aluminum nitride substrate template, which etches the low-temperature aluminum nitride layer on the low-temperature aluminum nitride layer through an in-situ high-temperature etching process. Holes with uniform distribution and uniform size can be produced, so as to solve the problem that the internal stress cannot be released due to lattice mismatch during the low-temperature aluminum nitride single crystal epitaxial growth process, and greatly improve the crystal quality of the aluminum nitride layer and the UVC-LED structure , photoelectric performance, reliability, etc.

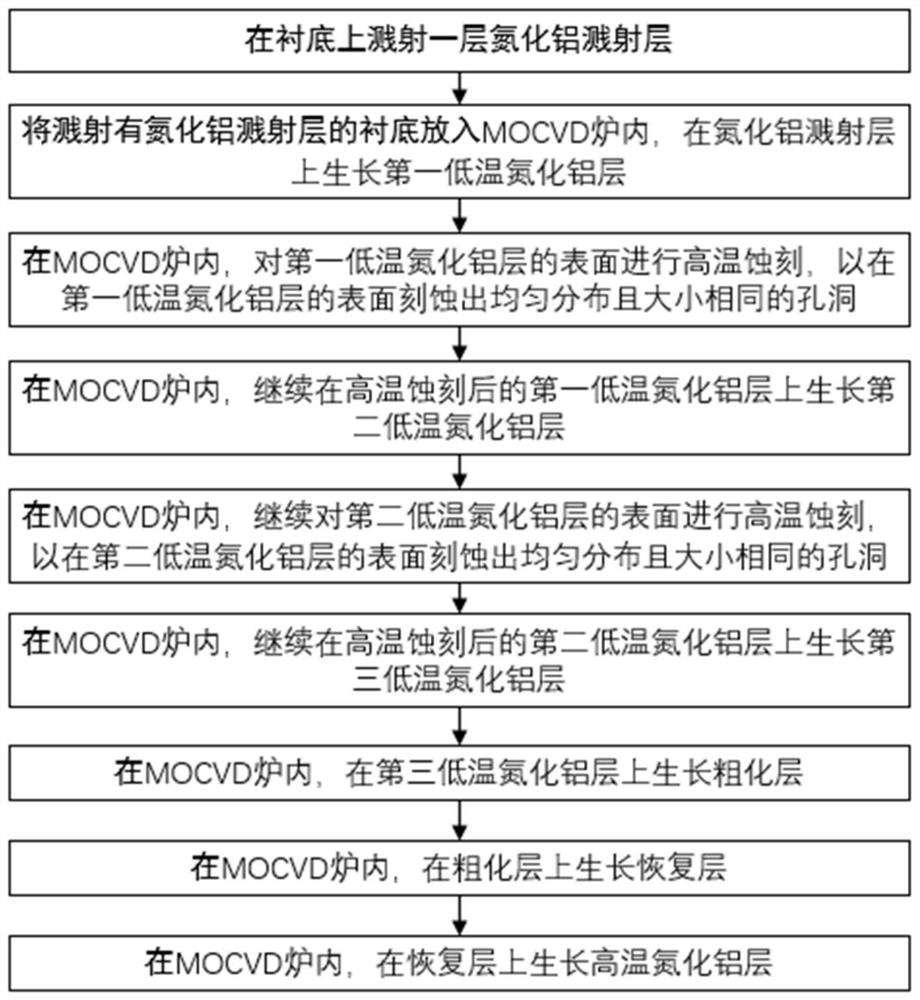

[0039] figure 1 A flow chart of the manufacturing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com