Sampling device for industrial enzyme mixed dust in workplace air

A workplace and sampling device technology, applied in the field of high-efficiency industrial enzyme preparation, can solve problems such as the deviation of the detection value of industrial enzyme mixed dust, and achieve the effects of reducing gas backflow, increasing pulling force, and reducing swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

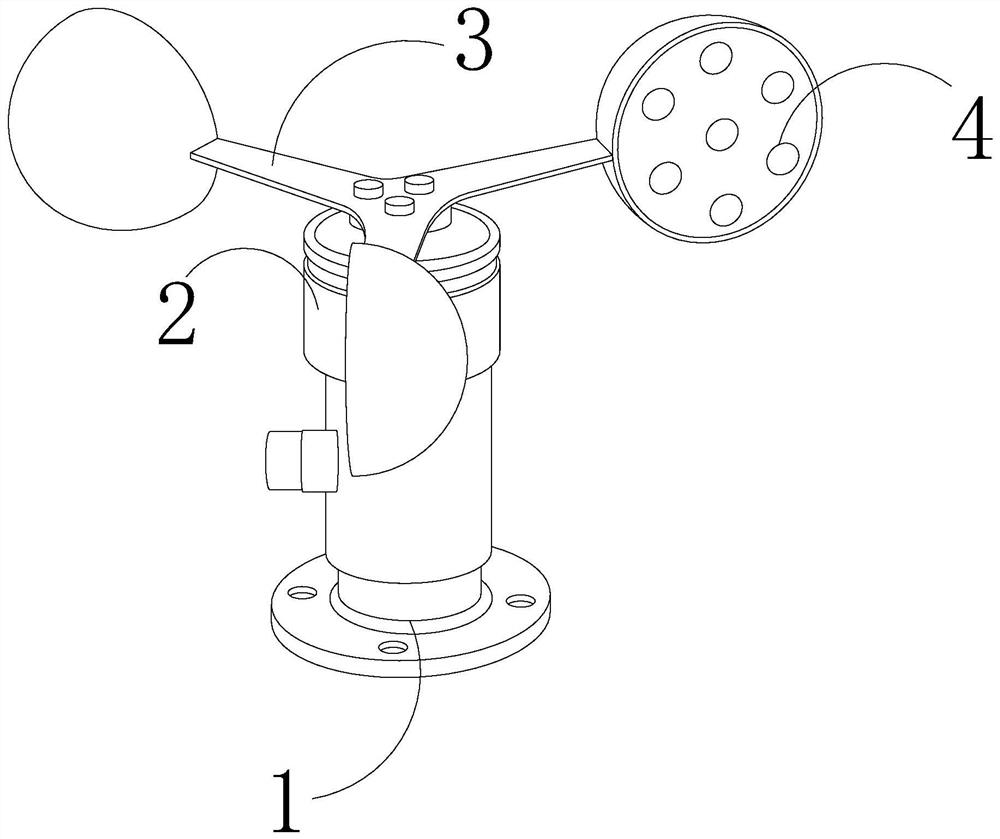

[0029] Append figure 1 Attachment Figure 5 Looking:

[0030] The present invention provides an industrial enzyme mixed dust sampling device in a working place air comprising a base 1, a motor 2, a rotating plate 3, a collected ball 4, and the motor 2 is fixed perpendicular to the top end of the base 1, the rotary plate 3 The middle of the bottom surface is fitted with the top end of the motor 2, the collecting ball 4 being mounted outside the rotating plate 3, respectively.

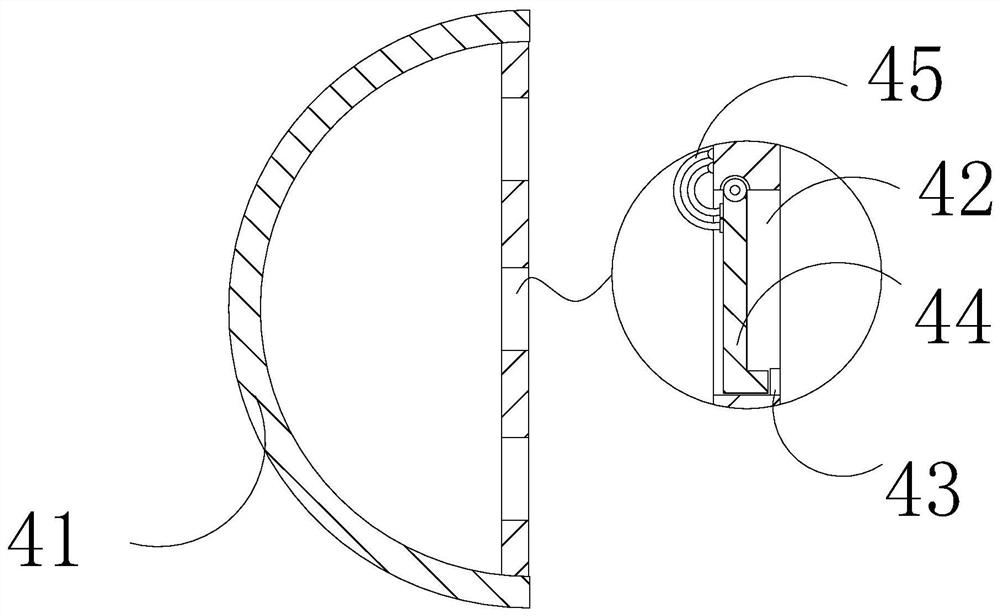

[0031] The collecting ball 4 includes a spherical body 41, an intake hole 42, a restricted block 43, a card plate 44, a reset strip 45, and the air hole 42 horizontally passes through the right side and the inner wall of the ball body 41, the limit block The bottom end is connected in the bottom of the intake hole 42, and the top end of the card plate 44 is hung inside the left side of the intake hole 42, and the reset strip 45 is close to the left side of the lock 44 near the top position. connect.

[0032] ...

Embodiment 2

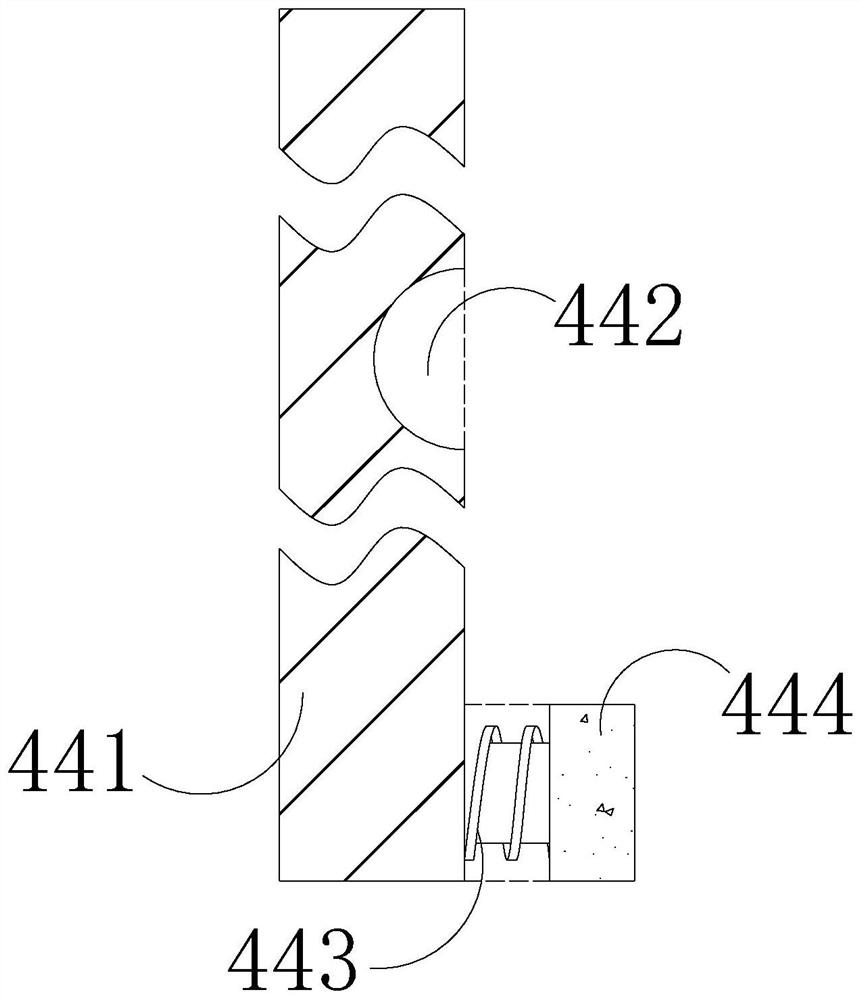

[0038] Append Image 6 Attachment Figure 9 Looking:

[0039] Wherein, the mating block 444 includes an adapter plate 44a, a telescopic block 44b, a block 44c, and the stretch block 44b is fixed to the right side of the adapter plate 44a, the left end of the block 44c, and the right end activity of the telescopic block 44b. The stretch block 44b is a rubber material, has a scalability, which facilitates the buffer of the block 44c, reducing the collision force of the lock 44c and the limit block 43, and reducing the cache 44 is rebounded.

[0040] Wherein, the block 44c includes a support block R1, a card slot R2, a magnetic ring C3, and the card slot R2 is opened between the upper surface and the inside of the support block R1, the magnetic ring C3, in the card slot R2, The upper right side of the magnetic ring C3 is provided with a bump, so that the right side of the magnetic ring C3 is the uneven surface, increasing the area of the right side of the magnetic ring C3, which is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com