Bacteriostatic and deodorant fiber material for face towel and preparation method of bacteriostatic and deodorant fiber material

A fiber material and face towel technology, applied in the field of antibacterial and deodorant fiber materials and their preparation, can solve problems such as affecting normal use, declining antibacterial effect of face towel, peculiar smell and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An antibacterial and deodorant fiber material used for face towels, which is made of synergistic fiber, acrylic fiber and vinylon;

[0035] The antibacterial and deodorant fiber material includes the following materials:

[0036] Step S1: Combine synergistic fibers, acrylic fibers, and vinylon fibers at a ratio of 1:2:2 to obtain composite fibers;

[0037] Step S2: heat-preserve the composite fiber for 10 minutes in a water bath at a temperature of 70° C. to prepare a pretreated fiber;

[0038] Step S3: Sodium octadecyl alcohol succinate monoester sulfonate sodium hydrochloride was dissolved in water to prepare a softening solution, and the pretreated fibers were soaked in the softening solution, and kept for 30 minutes in a water bath at a temperature of 70°C. The antibacterial and deodorizing fiber material is obtained by drying.

[0039] Synergistic fibers are made by the following steps:

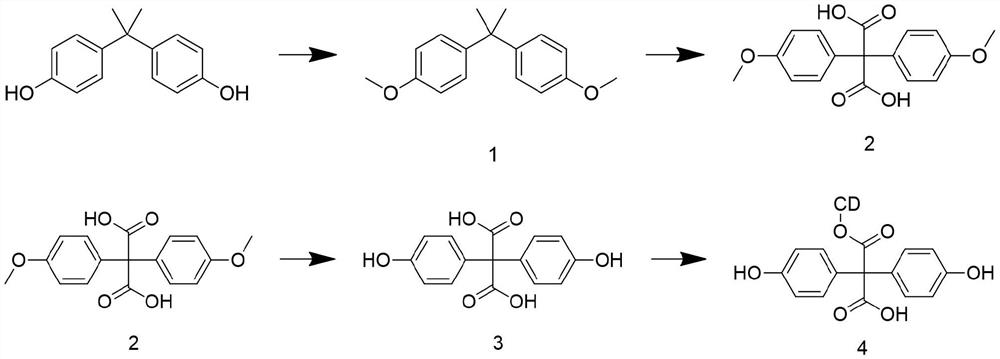

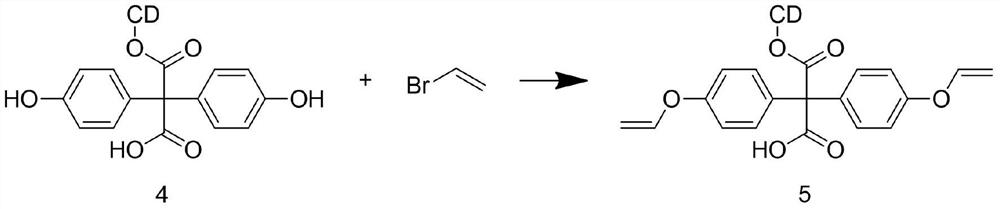

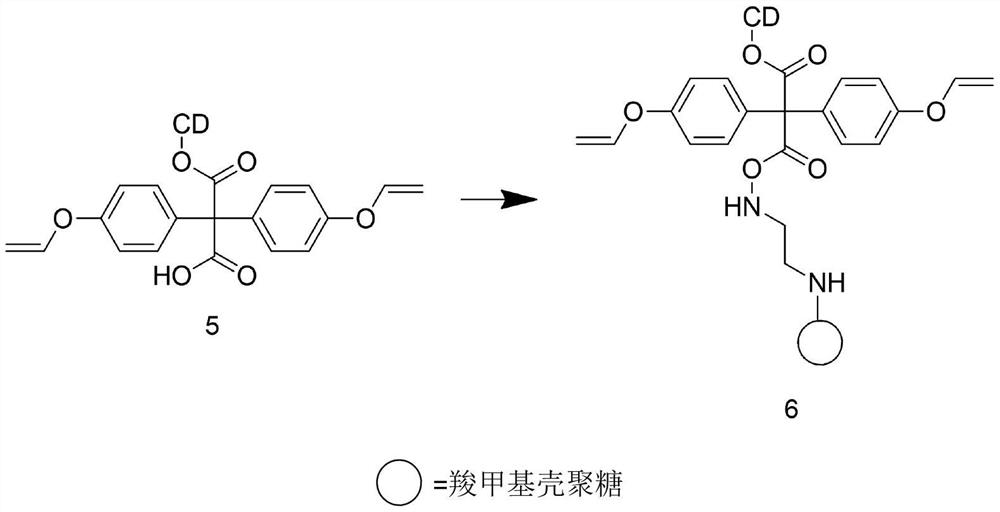

[0040]Step A1: Add 2,2-bis(4-hydroxyphenyl)propane, potassium carbonate, d...

Embodiment 2

[0045] An antibacterial and deodorant fiber material used for face towels, which is made of synergistic fiber, acrylic fiber and vinylon;

[0046] The antibacterial and deodorant fiber material includes the following materials:

[0047] Step S1: Combine synergistic fibers, acrylic fibers, and vinylon fibers at a root ratio of 1:2:2 to obtain composite fibers;

[0048] Step S2: heat-preserve the composite fiber for 13 minutes in a water bath at a temperature of 75° C. to obtain a pretreated fiber;

[0049] Step S3: Sodium octadecyl alcohol succinate monoester sulfonate sodium hydrochloride was dissolved in water to prepare a softening solution, and the pretreated fibers were soaked in the softening solution, and kept for 35 minutes in a water bath at a temperature of 75°C. The antibacterial and deodorizing fiber material is obtained by drying.

[0050] Synergistic fibers are made by the following steps:

[0051] Step A1: Add 2,2-bis(4-hydroxyphenyl)propane, potassium carbona...

Embodiment 3

[0056] An antibacterial and deodorant fiber material used for face towels, which is made of synergistic fiber, acrylic fiber and vinylon;

[0057] The antibacterial and deodorant fiber material includes the following materials:

[0058] Step S1: Combine synergistic fibers, acrylic fibers, and vinylon fibers at a root ratio of 1:2:2 to obtain composite fibers;

[0059] Step S2: heat-preserve the composite fiber for 15 minutes in a water bath at a temperature of 80° C. to obtain a pretreated fiber;

[0060] Step S3: Sodium octadecyl alcohol succinate monoester sulfonate sodium hydrochloride was dissolved in water to prepare a softening solution, soak the pretreated fibers in the softening solution, and heat preservation treatment for 40 minutes in a water bath at a temperature of 80°C. The antibacterial and deodorizing fiber material is obtained by drying.

[0061] Synergistic fibers are made by the following steps:

[0062] Step A1: Add 2,2-bis(4-hydroxyphenyl)propane, potas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com