Device for measuring impact force of tows and airflow in flash spinning process

A technology of flash spinning and impact force, which is applied in the direction of flash spinning, filament generation, textiles and papermaking, etc. It can solve the problem of changing other parameters, the impact force cannot be directly measured, and the quality uniformity per unit area of the finished product is affected. and other problems, to achieve the effect of improving the uniformity of unit mass and improving the degree of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

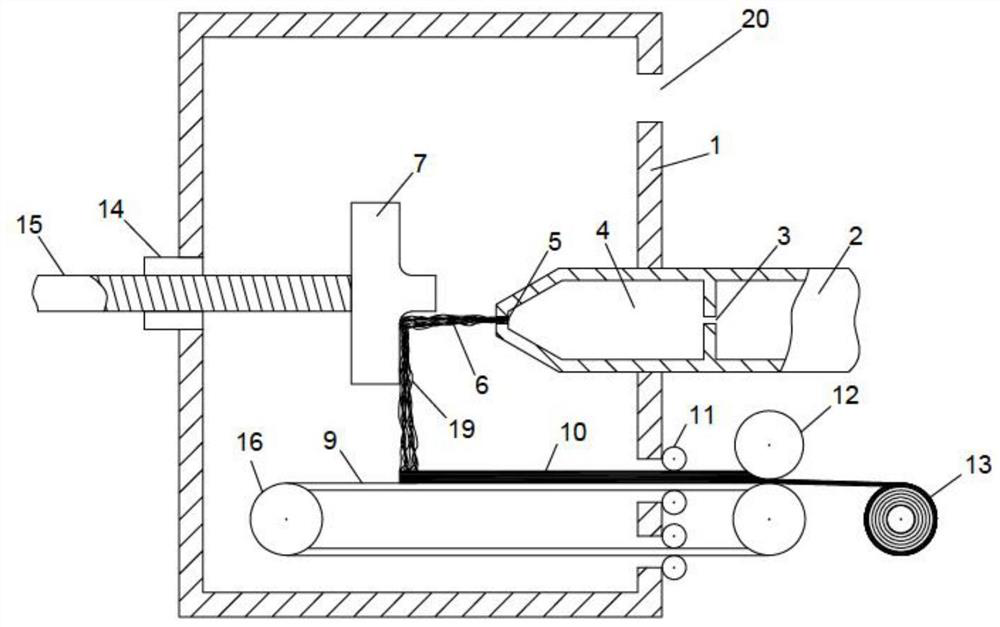

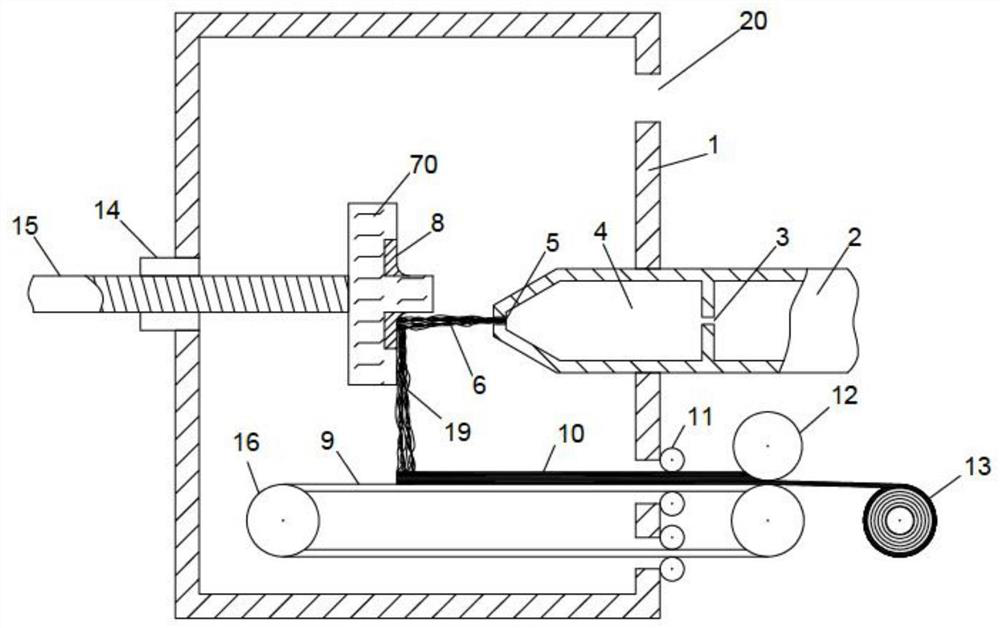

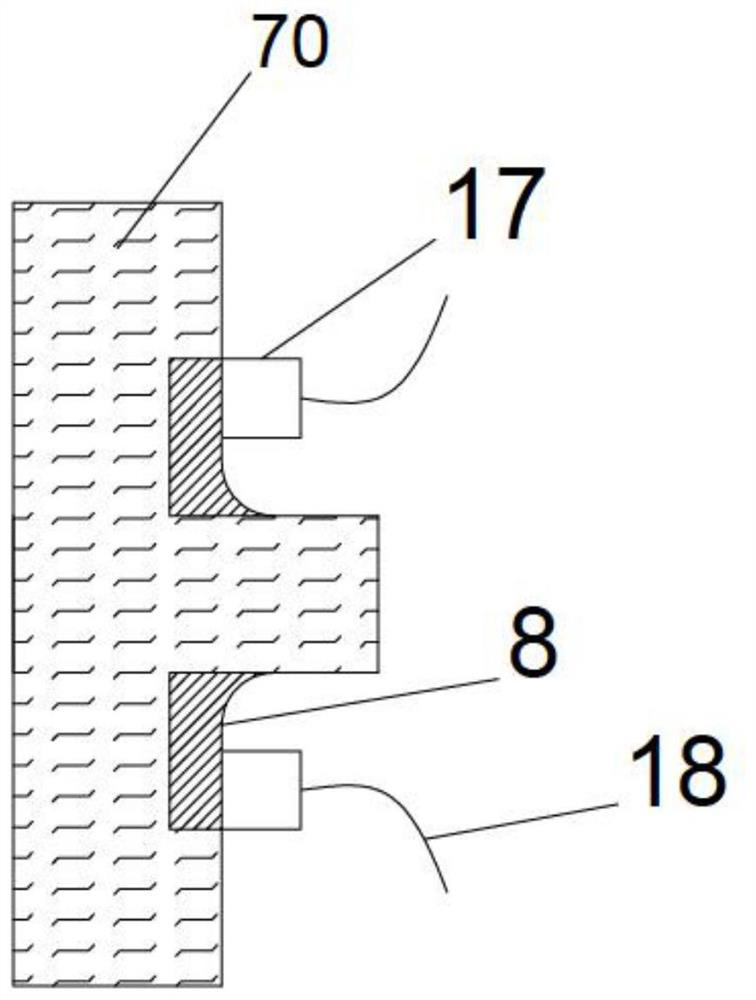

[0041] Please refer to Figure 2 to Figure 6 As shown, a device for measuring the impact force of tow and air flow in the flash spinning process, including: an insulating base plate 70, a pressure sensor 8, a brush 17, a constant force spring, a resistance meter 61 and a wire 18;

[0042]The insulating bottom plate 70 is a cylindrical structure, one bottom surface of the insulating bottom plate 70 faces the moving direction of the tow, and the center of the other bottom surface is connected to the rotating shaft of the flash spinning device, and the insulating bottom plate 70 has a surface facing the tow The annular cylindrical groove is used to receive the pressure sensor 8, the groove is set around a cylindrical protrusion, the pressure sensor 8 is made of piezoresistive material, and the pressure sensor 8 is embedded in the The groove rotates together with the insulating bottom plate 70, and the surface of the pressure sensor 8 is divided into an inner annular area and an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com