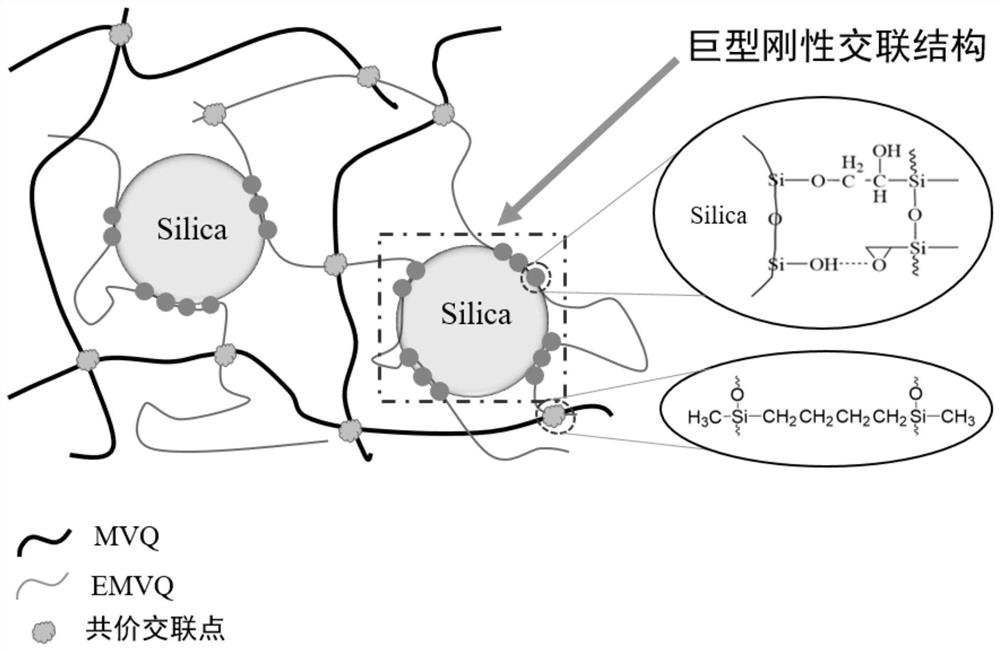

High-tear-resistance white carbon black/methyl vinyl silicone rubber composite material and preparation method thereof

A technology of methyl vinyl silicon and composite materials, which is applied in the field of polymer nanocomposites and can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

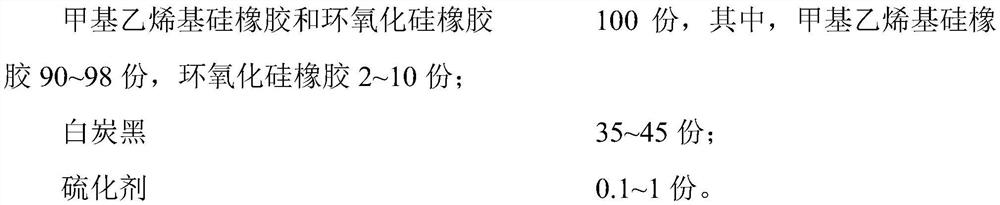

[0034] (1) In parts by weight, get 97.5 parts of methyl vinyl silicone rubber 110-2, 2.5 parts of epoxidized silicone rubber with an epoxy content of 15%, 40 parts of fumed white carbon black, vulcanizing agent (double two five) 0.1 copies;

[0035] (2) The roll temperature of the double-roll mill is room temperature. After the methyl vinyl silicone rubber 110-2 is pressed into thin sheets by the mill at room temperature, the vulcanizing agent and white carbon black are added in batches, and the mixture is uniform for 30 minutes. ;

[0036] (3) Add epoxy silicone rubber, and the mixing time is 30min;

[0037] (4) After being parked at room temperature for 24 hours, it was re-milled for 20 minutes, and vulcanized by a flat vulcanizer at 170°C for 10 minutes to prepare a vulcanized silicone rubber composite material.

Embodiment 2

[0039] (1): In parts by weight, get 97.5 parts of methyl vinyl silicone rubber 110-2, 2.5 parts of epoxidized silicone rubber with an epoxy content of 20%, 40 parts of fumed white carbon black, vulcanizing agent (double two five )0.1 part;

[0040] (2) The roll temperature of the double-roll mill is room temperature. After the methyl vinyl silicone rubber 110-2 is pressed into thin sheets by the mill at room temperature, the vulcanizing agent and white carbon black are added in batches, and the mixture is uniform for 30 minutes. ;

[0041] (3) Add epoxy silicone rubber, and the mixing time is 30min;

[0042] (4) After being parked at room temperature for 24 hours, it was re-milled for 20 minutes, and vulcanized by a flat vulcanizer at 170°C for 10 minutes to prepare vulcanized silicone rubber composites.

Embodiment 3

[0044] (1): In parts by weight, get 95 parts of methyl vinyl silicone rubber 110-2, 5 parts of epoxidized silicone rubber with an epoxy content of 10%, 40 parts of fumed white carbon black, vulcanizing agent (double two five )0.1 part;

[0045] (2) The roll temperature of the double-roll mill is room temperature. After the methyl vinyl silicone rubber 110-2 is pressed into thin sheets by the mill at room temperature, the vulcanizing agent and white carbon black are added in batches, and the mixture is uniform for 30 minutes. ;

[0046] (3) Add epoxidized silicone rubber, and the mixing time is 30 minutes.

[0047] (4) After being parked at room temperature for 24 hours, it was re-milled for 20 minutes, and vulcanized by a flat vulcanizer at 170°C for 10 minutes to prepare vulcanized silicone rubber composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com