Equipment and process for preparing 4,4'-bis(dimethylamino)diphenylcarbinol through catalytic oxidation

A catalytic oxidation and Michaelis alcohol technology, applied in the chemical industry, can solve the problems of frequent loading and unloading, production capacity constraints, etc., to achieve the effect of increasing cross-sectional area, increasing production capacity, and stabilizing automatic production

Pending Publication Date: 2021-10-22

大连第一有机化工有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the batch reaction has many repetitive operations such as frequent loading and unloading, repeated heating and cooling, etc., and the production capacity is restricted.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0049] Example 1: The flow rate of methane bass ethanol solution is 50ml / min, and the space velocity is 6 h -1 ; Conversion rate 92.2%.

Embodiment 2

[0050] Embodiment 2: methane bass ethanol solution flow rate 100ml / min, space velocity is 12 h -1 ; The conversion rate was 93.0%.

Embodiment 3

[0051] Embodiment 3: methane bass ethanol solution flow rate 200ml / min, space velocity is 24h -1 ; conversion rate 94.1%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

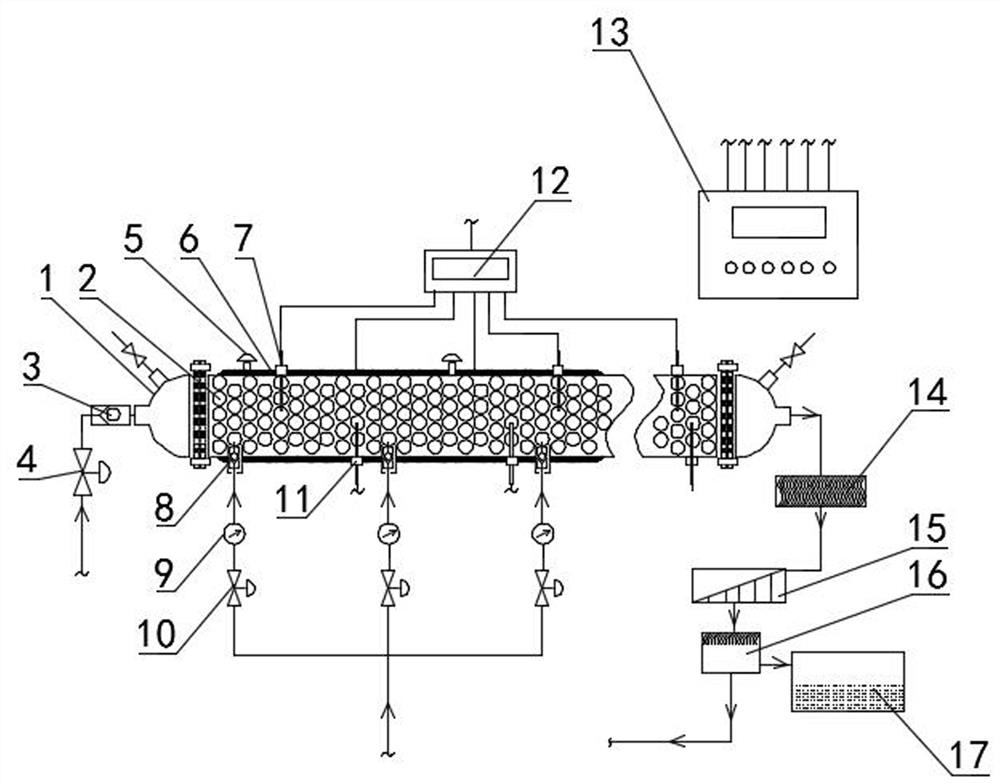

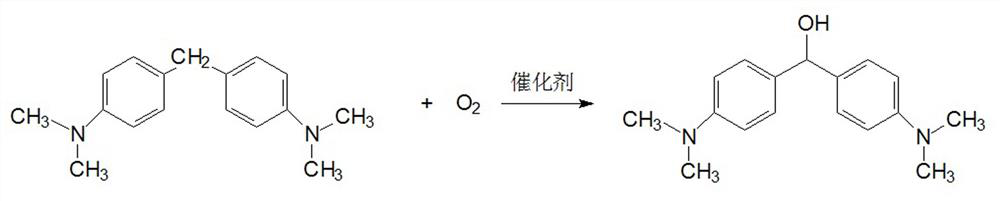

The invention discloses equipment and a process for preparing 4,4'-bis(dimethylamino)diphenylcarbinol through catalytic oxidation, and relates to the technical field of chemical engineering, the equipment comprises a shell, the shell is filled with a catalyst, the shell is connected with a feeding one-way valve, a feeding electromagnetic valve, a safety valve, a temperature sensor, an oxygen one-way valve and an oxygen concentration meter, and a heating belt wraps the shell; the outlet end of the shell is sequentially connected with a condenser, a gas-liquid separator, a reduced pressure distillation device and a cooling crystallizing pond through pipelines, and a temperature controller and a master controller are arranged outside the shell. According to the method, frequent loading and unloading and many repeated operations are avoided, continuous production can be achieved, and long-term stable operation can be achieved. Compared with an intermittent tank reactor, the system is higher in efficiency and better in energy saving performance; the continuous and stable automatic production can be realized by applying an accurate sensing and control system, the conversion rate and the product purity are ensured, a large amount of three wastes cannot be generated, and the device is suitable for popularization and application.

Description

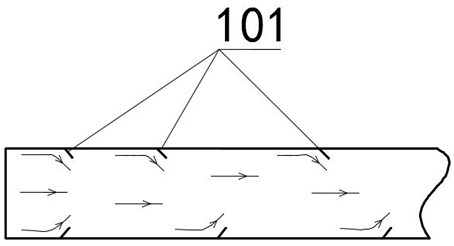

technical field [0001] The invention relates to the technical field of chemical industry, in particular to equipment and a process for preparing Mie alcohol by catalytic oxidation. Background technique [0002] Today's chemical industry is more and more developed. For example, Mieter alcohol is an important pharmaceutical and dye intermediate with a wide range of uses. As the main raw material of the dye crystal violet lactone (CVL), Mieter alcohol is in great demand in the market. Usually, Methane Bess (4,4'-bisdimethylaminodiphenylmethane) and oxygen are used as raw materials to prepare Michaelis alcohol through a catalytic oxidation process. [0003] According to the public information, the domestic use of oxidation method to produce Michaelis alcohol, generally adopts batch production of reactor. The reaction was simulated in the laboratory, using a supported multi-element metal oxide catalyst, oxygen was supplied by air bubbling, and the reaction time was 120 minutes ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C213/00C07C215/68

CPCC07C213/00C07C215/68

Inventor 邹德强张云邦农彩烟郑学德

Owner 大连第一有机化工有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com