Method for improving strength of calcium hydroxide carbonized hardened body and product

A calcium hydroxide and calcium hydroxide technology, applied in methods and products to improve the strength of calcium hydroxide carbonized hardened body, can solve the problems of low carbonized hardened body strength, poor cementation of calcium carbonate grains, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

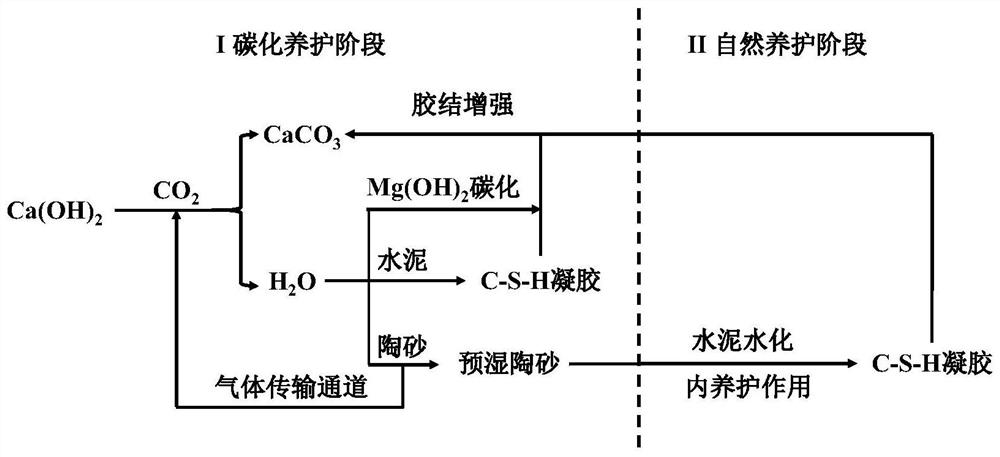

Method used

Image

Examples

Embodiment 1

[0033] After mixing 100 parts of calcium hydroxide, 20 parts of ordinary portland cement, 20 parts of magnesium hydroxide and 15 parts of water evenly, add 50 parts of pottery sand, continue to mix evenly, form under 15MPa pressure, and carbonize in the carbonization reactor. The carbonization conditions are as follows: the carbonization curing temperature is 25°C, the relative humidity is 50%, the carbon dioxide concentration is 99.8%, the air pressure is 0.1MPa, the carbonization time is 8h, and after carbonization curing, it is naturally cured at 20°C to the specified age.

[0034] The obtained calcium hydroxide carbide hardening body 1d compressive strength of embodiment 1 is 60MPa, and the 7d compressive strength is 75MPa.

Embodiment 2

[0036] After mixing 100 parts of calcium hydroxide, 20 parts of ordinary portland cement, 20 parts of magnesium hydroxide and 10 parts of water, add 50 parts of pottery sand, continue to mix evenly, form under 15MPa pressure, and carbonize in the carbonization reactor. The carbonization conditions are carbonization curing temperature of 25°C, relative humidity of 50%, carbon dioxide concentration of 99.8%, air pressure of 0.1MPa, carbonization time of 8 hours, and natural curing at 20°C to the specified age after carbonization curing.

[0037] The obtained calcium hydroxide carbide hardening body 1d compressive strength of embodiment 2 is 49MPa, and the 7d compressive strength is 62MPa.

Embodiment 3

[0039] After mixing 100 parts of calcium hydroxide, 20 parts of ordinary portland cement, 20 parts of magnesium hydroxide and 20 parts of water evenly, add 50 parts of pottery sand, continue to mix evenly, form under 15MPa pressure, and carbonize in the carbonization reactor. The carbonization conditions are carbonization curing temperature of 25°C, relative humidity of 50%, carbon dioxide concentration of 99.8%, air pressure of 0.1MPa, carbonization time of 8 hours, and natural curing at 20°C to the specified age after carbonization curing.

[0040] The obtained calcium hydroxide carbide hardening body 1d compressive strength of embodiment 3 is 53MPa, and the 7d compressive strength is 69MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com