Reversible conveying mechanism for circuit board production and conveying

A technology of conveying mechanism and reversing mechanism, which is applied in the direction of conveyor objects, transportation and packaging, roller table, etc., which can solve the problems of affecting work efficiency, large occupied area, and increased cost, and achieves convenient control, small occupied area, and high work efficiency. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

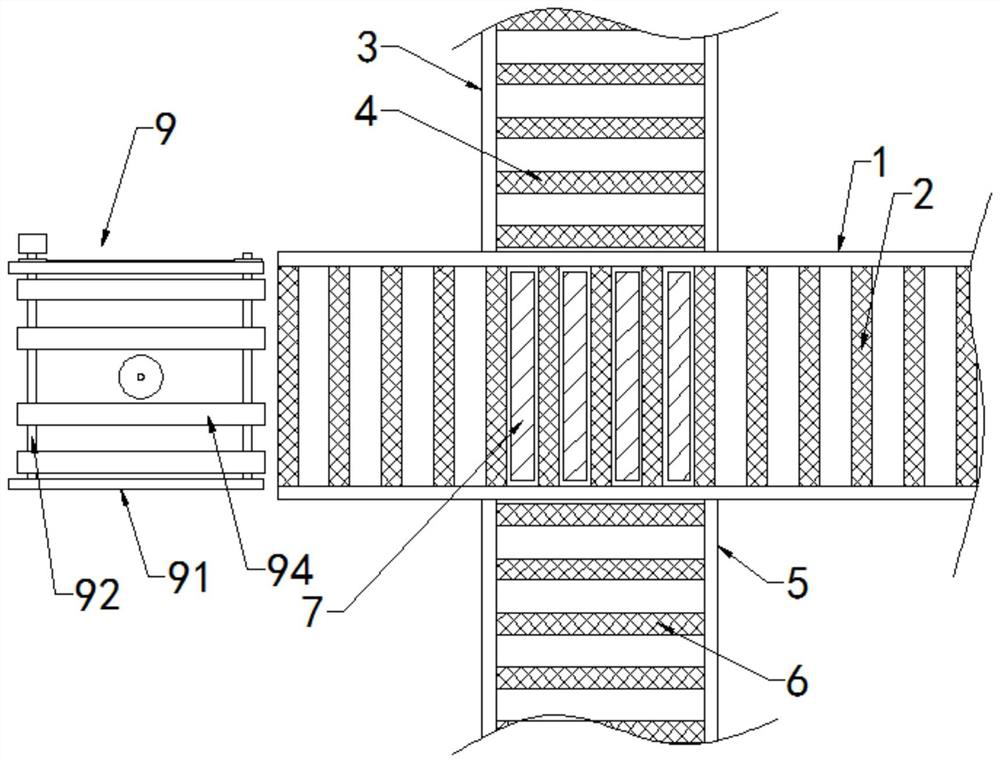

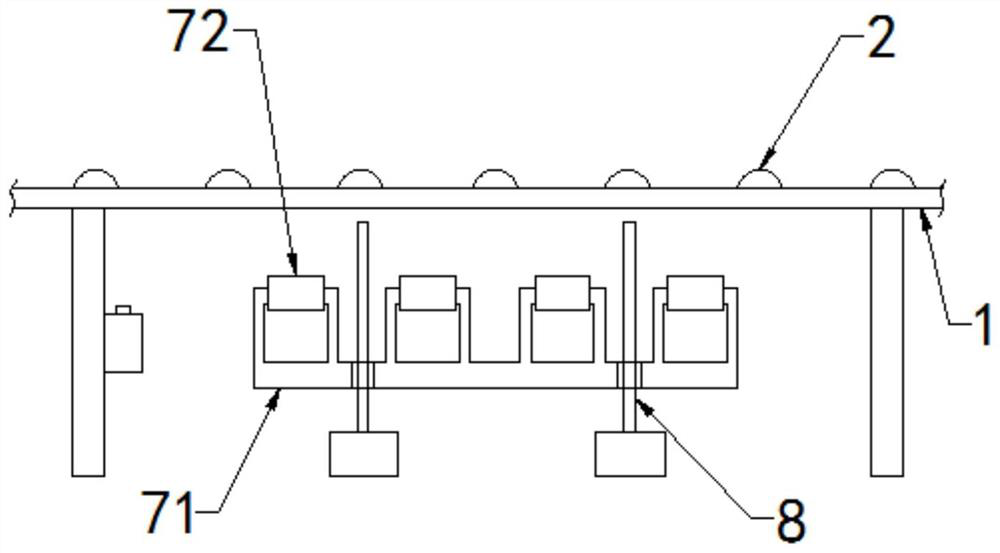

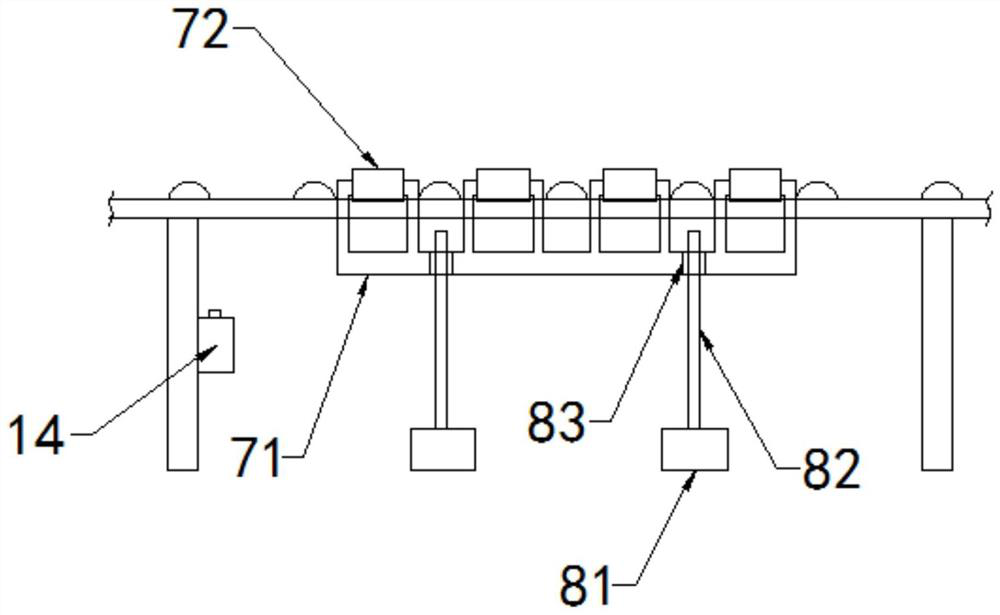

[0031] Such as Figure 1 to Figure 4 As shown, the present invention discloses a reversible conveying mechanism for the production and conveying of circuit boards. In a specific embodiment of the present invention, it includes a first conveying bracket 1 horizontally arranged on the left and right, and on the first conveying bracket 1 There are first conveying rollers 2 and a first driving mechanism for controlling the forward and reverse rotation of the first conveying rollers 2, and the first conveying rollers 2 are arranged at intervals, and the left side of the first conveying bracket 1 is connected with a rotating plate Mechanism 9, the rotating plate mechanism 9 is used to transport the circuit board to the first conveying roller 2 and rotate the circuit board; one side of the first conveying support 1 is vertically provided with a second conveying support 3, the The second conveying support 3 is provided with a second conveying roller and a second driving mechanism for ...

Embodiment 2

[0040] Such as Figure 5 and Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that, in this embodiment, the rotating plate mechanism 9 also includes an adsorption unit 10, and the adsorption unit 10 includes two sides of the cylinder 97 with Two elastic balls 101 in the air cavity, the upper and lower ends of the elastic balls 101 are fixedly connected with the horizontal plate 96 and the mounting seat 95 respectively, the rotating rod 99 is set as a hollow structure, and the upper end of the rotating rod 99 is open, the The elastic ball 101 communicates with the rotating rod 99 through the air pipe 102; when the cylinder 97 drives the supporting plate 991 to be positioned at the upper end of the second conveyor belt 94, the elastic ball 101 is a sphere; At this time, the elastic ball 101 is compressed by the horizontal plate 96 to form an oblate spheroid.

[0041] Through the above technical scheme, when the cylinder does not control the rising...

Embodiment 3

[0046] Such as Figure 7 and Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that, in this embodiment, a correcting mechanism 11 is provided on the upper end of the first conveying roller 2 on the first conveying frame, and the correcting mechanism 11 includes setting Fixed plates 111 on both sides of the first conveying roller 2, the fixed plates 111 are fixed on the first conveying support 1, and the end of the fixed plate 111 facing the first conveying roller 2 is provided with a film body 112, the film body 112 A cavity that can be filled with gas is provided inside, and a correction channel 113 is formed between the membrane bodies 112 on both sides, and the width of the correction channel 113 gradually decreases from the input end to the output end of the first delivery stent 1 .

[0047] In this embodiment, a rubber layer 114 is provided on the side of the membrane body 112 facing the middle of the first conveying roller 2 .

[0048] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com