A double-chain multi-mode peeling device for copper rods

A copper rod and pull rod technology, applied in the field of copper rod double-chain multi-mode peeling device, can solve the problems of affecting the surface accuracy of copper rod peeling, waste of raw materials, easy trembling, etc., to prevent bending deformation, convenient operation, and good support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make those skilled in the art better understand the patented solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

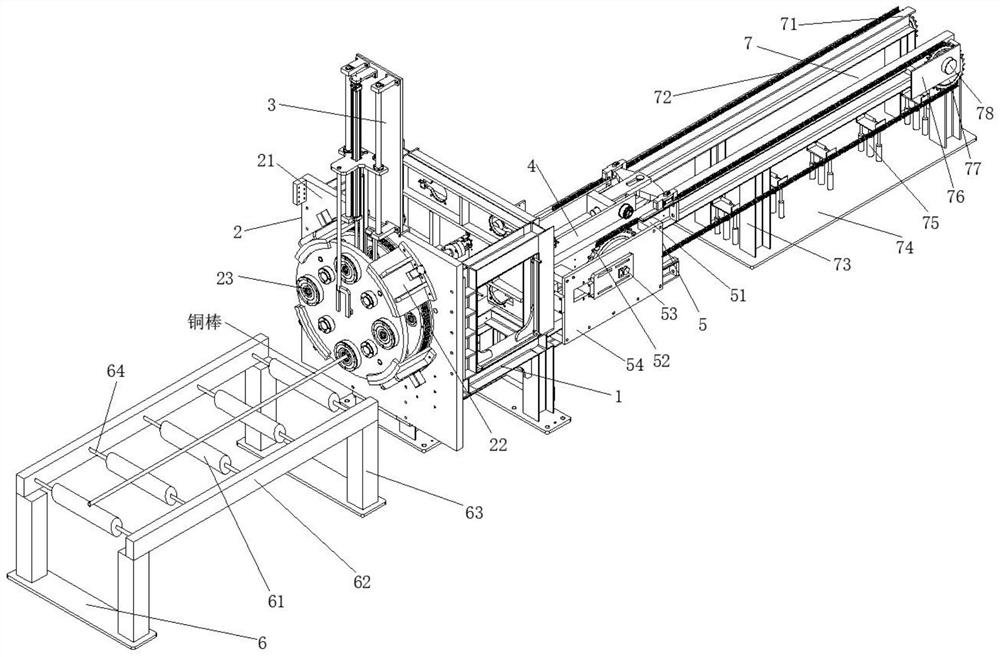

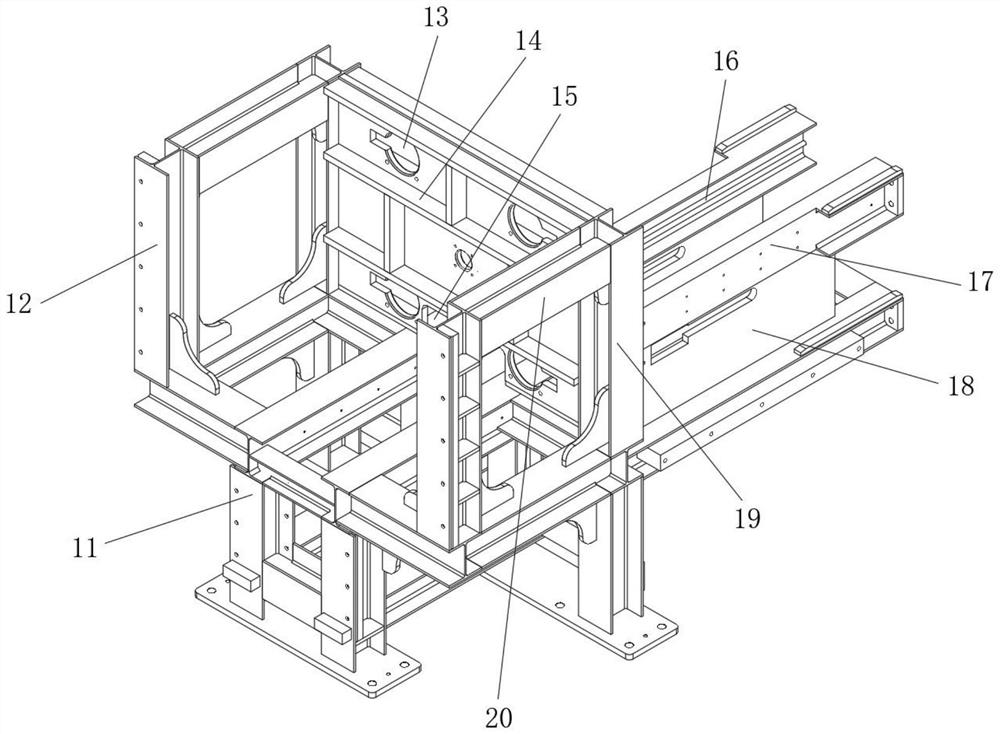

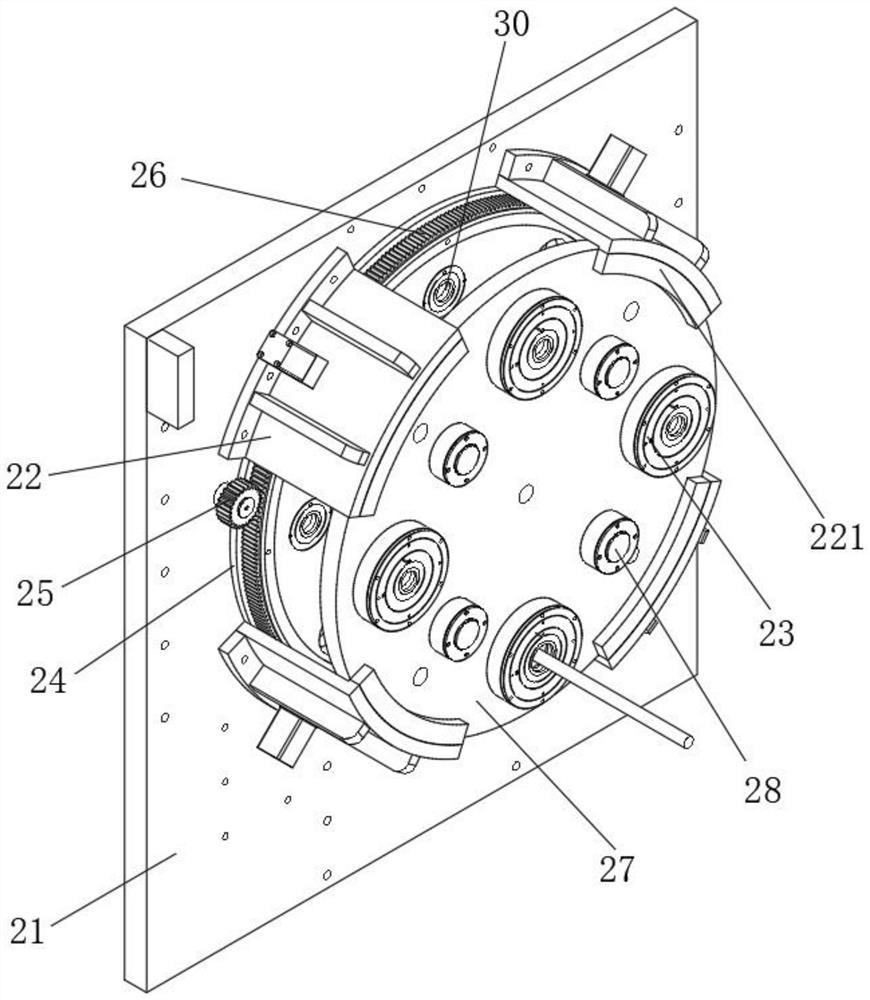

[0027] like Figure 1-9 As shown in the figure, a double-chain multi-mode peeling device for copper rods is provided, including a bracket 1, and a peeling mechanism 2 and a pulling rod trolley 4 are arranged on the bracket 1 in turn. The pulling rod trolley 4 includes a trolley body 41 and a The rod clamping mechanism 42 on the trolley body 41, the front and rear sides of the bracket 1 located on both sides of the pulling rod trolley 4 are symmetrically provided with a transmission mechanism 5, and the peeling mechanism 2 is provided with a chip mechanism 3, which is close to the peeling mechanism. 2, a rod feeding device 6 is placed on one side of the bracket 1, and a conveying mechanism 7 is placed on one side of the bracket 1 next to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com