A semiconductor quartz component cleaning equipment

A technology for cleaning equipment and semiconductors, applied in the directions of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of water stains, transfer, and numerous water stains on quartz parts, and reduce dumping. Falling, improve cleaning effect, good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

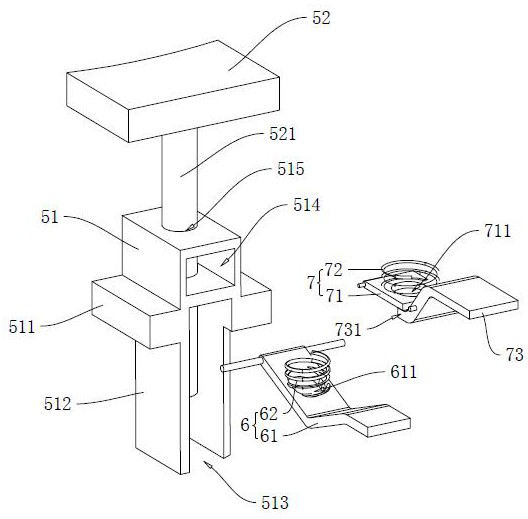

[0036] The following is attached Figure 1-4 The present invention is described in further detail.

[0037] The embodiment of the present application discloses a semiconductor quartz component cleaning equipment, referring to figure 1 , including a frame 1, a placement table 2, an outer tube wall cleaning device 3 and an inner tube wall cleaning device 4, the frame 1 is used as a supporting body, and it is a box-type structure. A stepped installation groove 11 is provided on the table surface of the frame 1 , and the placement platform 2 is in the shape of a circular platform, with rotating meshing teeth 21 arranged on its circumferential side wall, and the placement platform 2 is placed in the installation groove 11 .

[0038] refer to figure 2 In order to drive the placement table 2 to rotate, a rotating motor 12 is fixed on the side wall of the frame 1, a rotating worm 13 is fixed on the output shaft of the rotating motor 12, and the rotating worm 13 enters the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com