System for preparing isopropanol through propylene hydration reaction

A technology of propylene hydration and isopropanol, which is applied in the preparation of hydroxyl compounds, the preparation of organic compounds, the separation/purification of hydroxyl compounds, etc., to achieve the effects of improving the effect, improving the mixing effect, and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

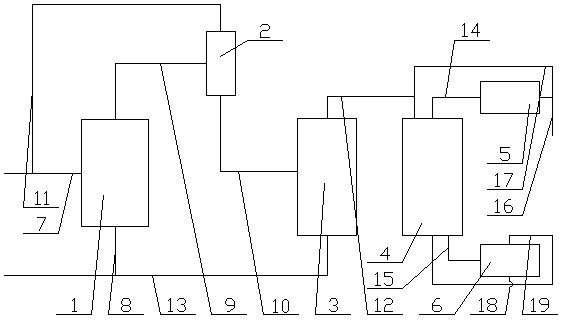

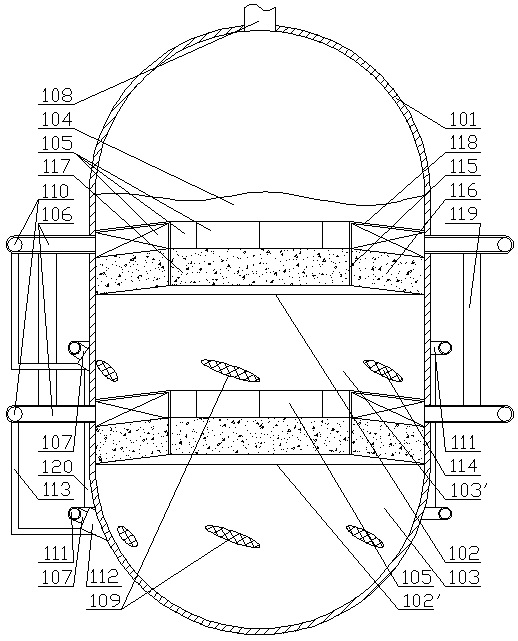

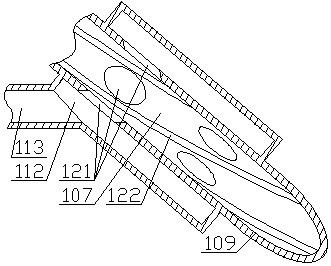

[0043] combine Figure 1~Figure 4 It can be seen that the system for preparing isopropanol by propylene hydration reaction includes a reactor 1, the top of the reactor 1 is communicated with the feed port A of the gas-liquid separator 2 through a pipeline A9, and the liquid outlet of the gas-liquid separator 2 Port A is communicated with the feed port B of the dehydration tower 3 through the pipeline B10, and the gas outlet A of the gas-liquid separator 2 is communicated with the propylene gas supply pipe 7 of the reactor 1 through the pipeline C11, and the gas outlet B of the dehydration tower 3 is connected through the The pipeline D12 is condensed by a condenser (not shown in the accompanying drawings) and then communicated with the feed port C of the purification tower 4, and the liquid outlet B of the dehydration tower 3 is connected to the pure water supply pipe 8 of the reactor 1 through the pipeline E13 The gas outlet C of the purification tower 4 is communicated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com