High-temperature flue gas washing, concentrating and desalting device and desalting method

A high-temperature flue gas and desalination device technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of difficult biochemical treatment, high-salt wastewater, hydrogen chloride gas entering the flue gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

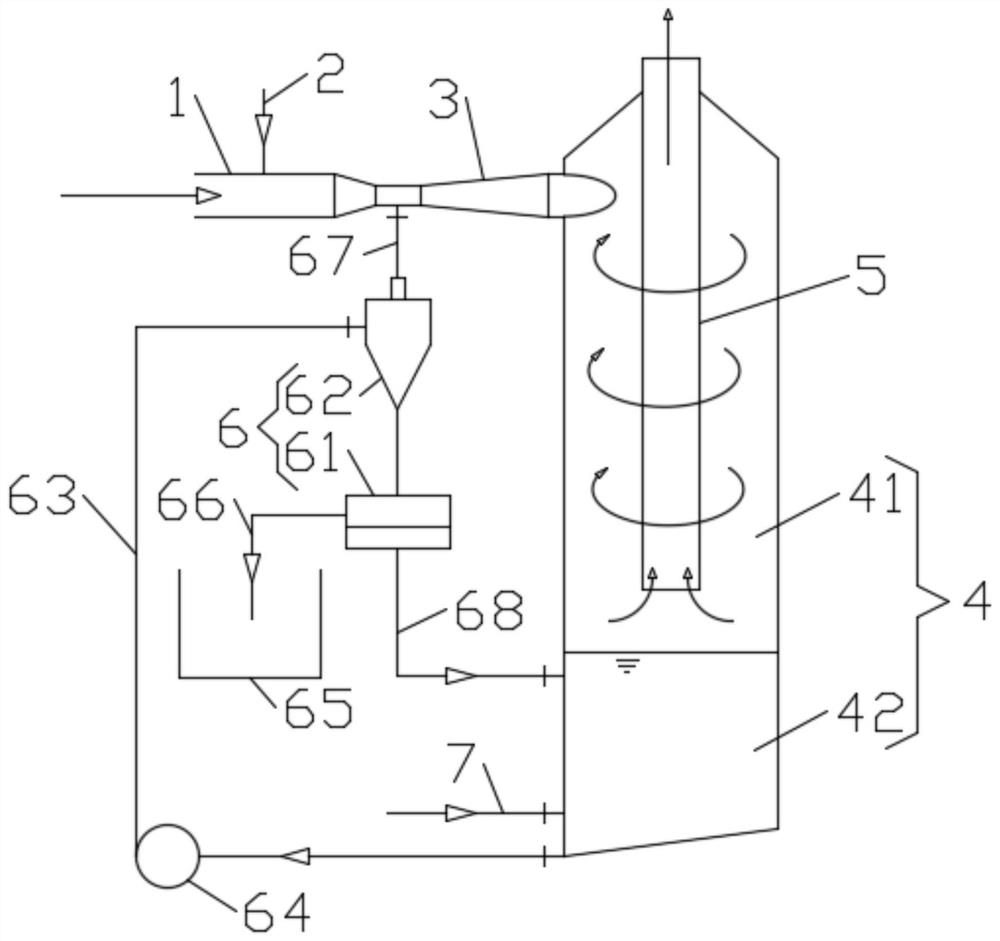

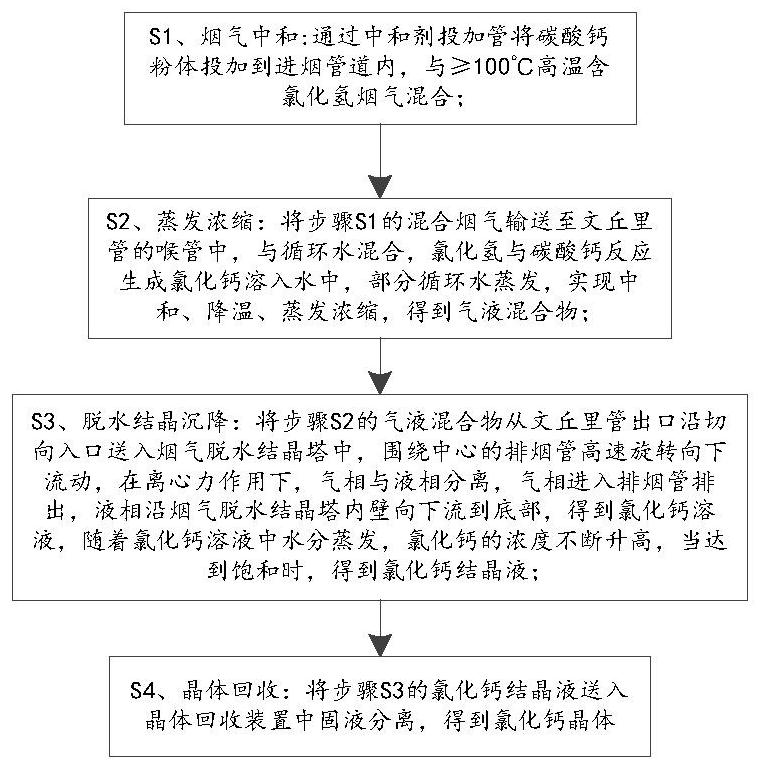

[0043] Such as figure 1 As shown, the present invention provides a high-temperature flue gas washing concentration desalination device, including:

[0044] The smoke inlet pipe 1 used to transport high-temperature flue gas containing hydrogen chloride is provided with a neutralizer dosing pipe 2 on the smoke inlet pipe 1, and one end of the neutralizer dosing pipe 2 is connected to the smoke inlet pipe 1; it should be noted that, The neutralizing agent dosing pipe 2 is used to transport and add calcium carbonate powder to the smoke inlet pipe, and the calcium carbonate powder and high-temperature flue gas are mixed in the neutralization pipe 1 to form mixed flue gas.

[0045] Venturi tube 3, one end of the Venturi tube 3 is connected to the smoke inlet pipe 1, the other end of the Venturi tube 3 is connected to the flue gas dehydration crystallization tower 4, and the throat of the Venturi tube 3 is provided with a circulating water inlet pipe;

[0046] The flue gas dehydrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com