desalination

A compartmental, ion-based technology, applied in the field of desalination, which can solve the problems of large concentration differences, high water loss, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

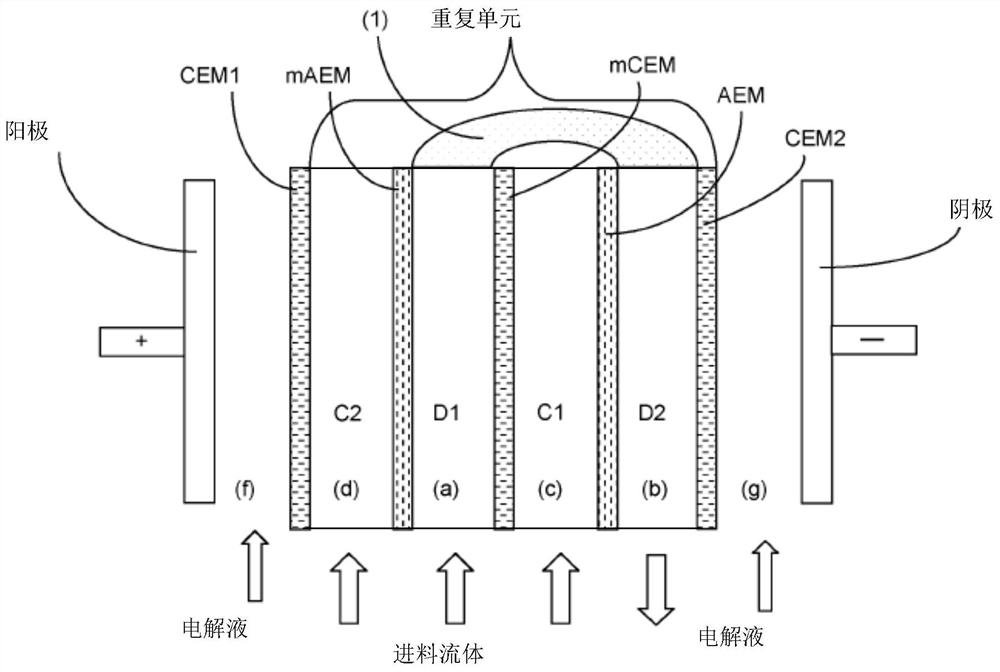

[0220] Membrane stack MS1 containing 81 membranes was constructed. The order of the membranes in the stack is [CEM-AEM-mCEM-mAEM-] n CEM, where n is 20. The membranes mCEM and mAEM are located on each side of compartment (a), and the membranes CEM and AEM within square brackets are located on each side of compartment (b). Thus, the stack comprises repeating units of compartments [(b), (c), (a), (d)] n .

[0221] The stack consisted of the membranes in the above sequence, a spacer between each membrane and the next (a 480 μm thick woven spacer from Deukum GmbH), one inlet for the feed liquid, two inlets for the concentrate , one outlet for the desalted liquid and two outlets for the concentrate and pipes fluidly connecting each compartment (a) with compartment (b).

[0222] In addition, the stack is configured such that fluid passing through compartment (a) flows in the opposite direction to fluid passing through compartment (b), and between fluids passing through compartme...

example 2

[0254] Similar simulation experiments were performed, but the flow between ED units was in a co-current direction. For these three steps, the same feed fluid requiring desalination and the same settings as in Example 1 were used. Therefore, the feed fluid that needs to be desalted is used as input to the ion diluting compartment (a) and concentrating compartments (c) and (d) of EDM1. Fluid flowing out of compartment (a) of EDM1 is also fed into compartment (b) of EDM1. The fluid flow was recirculated through compartments (a) and (b) of EDM1 until the conductivity of the fluid to be desalinated decreased to 27.1 mS / cm, while the fluid flow out of compartments (c) and (d) were respectively Recirculation back through compartments (c) and (d) of EDM1. The three fluid streams exiting compartments (b), (c) and (d) of EDM1 are respectively fed into compartments (a), (c) and (d) of EDM2 for the second step. In the second step, the fluid to be desalinated is recirculated through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com