Method for degrading aminobenzene or/and nitrobenzene in waste water by electrolytic process

A nitrobenzene, electrolysis technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficulty in ensuring stable compliance, high price, and low removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

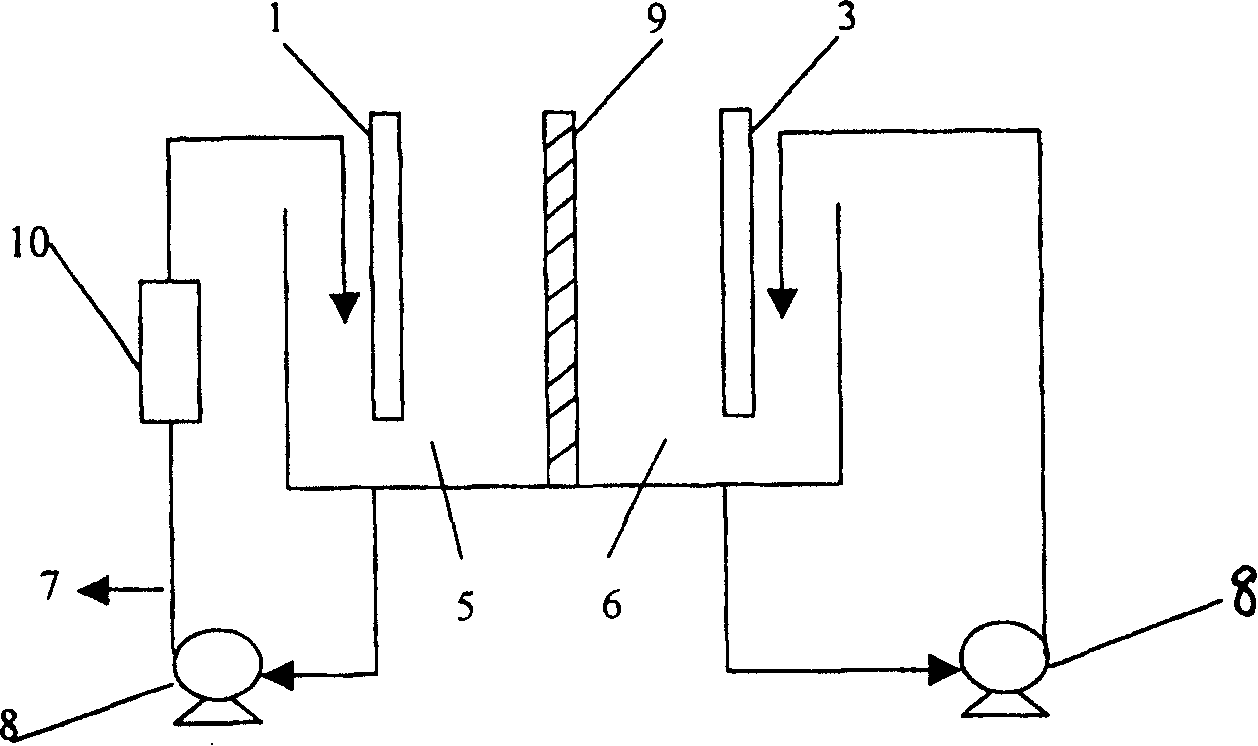

[0022] M type dye wastewater, aniline concentration 210mg / l, nitrobenzene concentration 240mg / l, salt content 15g / l, chroma 3500 times. Get waste water 500ml and place in electrolyzer anode chamber 5, as figure 2 shown. Get 500ml of 0.5% NaOH solution and place it in the cathode chamber 6 of the electrolyzer, and circulate with circulation pump 8 respectively. The material of 1 is titanium base coated with ruthenium (produced by Future Water Chemical Co., Ltd., Xinxiang City, Henan Province), the material of cathode 3 is stainless steel, the specification is 0.2×0.4m, and the circulating liquid flow rate of anode chamber 5 and cathode chamber 6 is 20L / h , the wastewater in the anode chamber 5 is controlled by the electric heater 10 at a temperature of 60° C., pH=4, under a DC electric field voltage of 3 V, and a cycle time of 3 hours. After the shutdown, sampling and analysis are performed. After treatment, the removal rate of aniline in the wastewater was 97.5%, the remova...

Embodiment 2

[0024] K-type dye wastewater, aniline concentration 175mg / l, nitrobenzene concentration 199mg / l, salt content 10g / l, chroma 4000 times. Get waste water 500ml and place in electrolyzer anode chamber 5, as figure 2 shown. Get 500ml of 4% NaOH solution and place it in the cathode chamber 6 of the electrolyzer without pump circulation. The cation exchange membrane 9 is a polyethylene heterogeneous cation exchange membrane (the 3362BW type produced by Shanghai Shanghua Water Treatment Material Co., Ltd.), and the material of the anode 1 Coating iridium on a titanium base (produced by Future Water Chemical Co., Ltd., Xinxiang City, Henan Province), the material of the cathode 3 is stainless steel, the specification is 0.2×0.4m, and the temperature of the waste water in the anode chamber 5 is controlled by a heater 10 to be 40° C., pH=6 , under the DC field voltage of 4V, the cycle time is 3h. Sampling analysis after shutdown, after treatment, the removal rate of aniline in the wa...

Embodiment 3

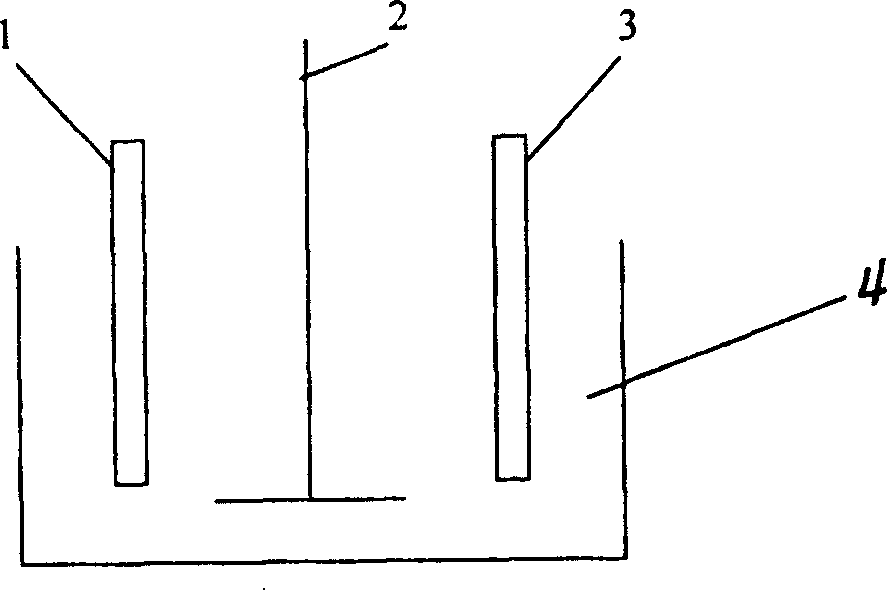

[0026] Nitrobenzene production wastewater, aniline concentration 340mg / l, nitrobenzene concentration 284mg / l. Get waste water 500ml and place in the electrolyzer 4 that has stirrer 2, as figure 1 As shown, the material of the anode 1 is titanium-based coated lead dioxide (Henan Xinxiang City Future Water Chemical Co., Ltd.), the material of the cathode 3 is graphite (Nantong Carbon Factory), and the temperature of the wastewater in the electrolytic cell is controlled by a heater to normal temperature (25°C), DC electric field voltage 10V, electrolysis time 3h. Sampling and analysis after shutdown showed that the removal rate of aniline in the treated wastewater was 95.4%, 83.2% of nitrobenzene, 85.2% of TOC, and 75% of chroma.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com