A kind of desalination method of producing l-alanine feed liquid by fermentation method

A technology of alanine and fermentation method, applied in the direction of organic chemistry method, chemical instrument and method, preparation of organic compounds, etc., can solve the problems affecting the quality of L-alanine, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

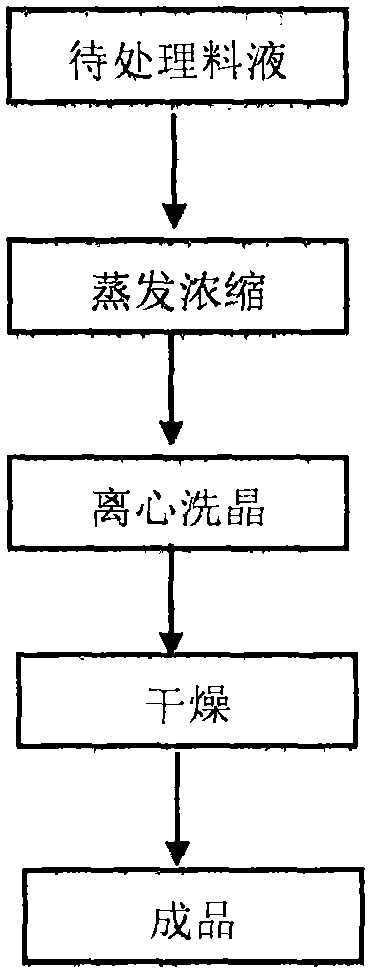

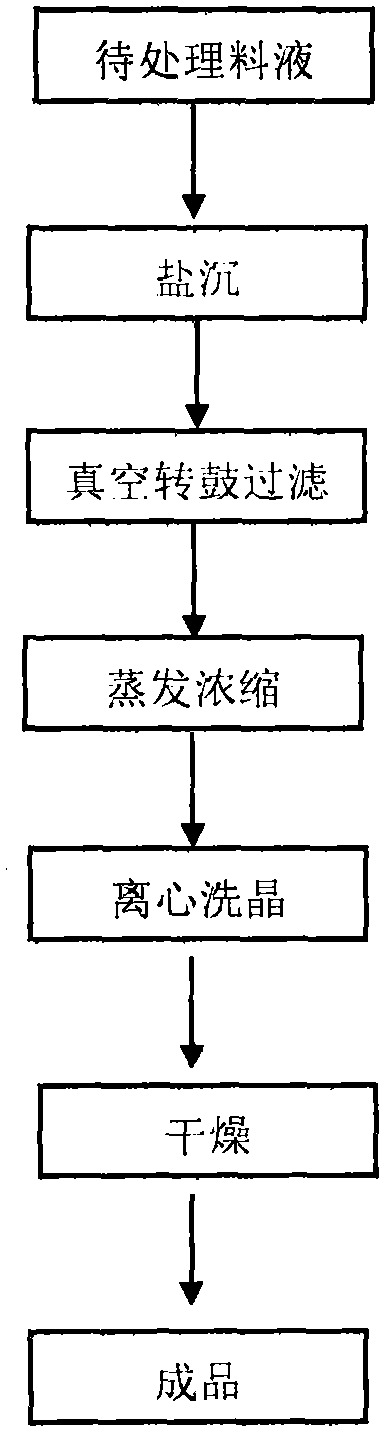

Image

Examples

Embodiment 1

[0033] The phosphate content in the feed liquid to be treated is 4260ppm, and the ammonium salt content is 6573ppm. Use caustic soda to adjust its pH value to 8.5, add 0.06% magnesium oxide, stir and mix. The rotation speed of the vacuum drum is 1.5r / min, and the vacuum degree is 0.03-0.08MPa. After salt precipitation, vacuum drum filtration, evaporation crystallization and other processes, the phosphate content in the resulting finished product is 153ppm, and the ammonium salt content is 84ppm. Compared with the original process, the removal rate of phosphate is increased by about 76.5%, and the removal rate of ammonium salt is increased by 79%.

Embodiment 2

[0035] The phosphate content in the feed liquid to be treated is 3763ppm, and the ammonium salt content is 5941ppm. Use caustic soda to adjust its pH value to 8.5, add 0.08% calcium oxide, stir and mix. The rotation speed of the vacuum drum is 1.5r / min, and the vacuum degree is 0.03-0.08MPa. After salt precipitation, vacuum drum filtration, evaporation crystallization and other processes, the phosphate content in the resulting finished product is 182ppm, and the ammonium salt content is 106ppm. Compared with the original process, the removal rate of phosphate is increased by about 73.5%, and the removal rate of ammonium salt is increased by 77.2%.

Embodiment 3

[0037] The phosphate content in the feed liquid to be treated is 5794ppm, and the ammonium salt content is 7201ppm. Use caustic soda to adjust its pH value to 7.5, add 0.08% magnesium oxide, stir and mix. The rotation speed of the vacuum drum is 1.5r / min, and the vacuum degree is 0.03-0.08MPa. After salt precipitation, vacuum drum filtration, evaporation crystallization and other processes, the phosphate content in the resulting finished product is 173ppm, and the ammonium salt content is 113ppm. Compared with the original process, the removal rate of phosphate is increased by about 73.4%, and the removal rate of ammonium salt is increased by 71.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com