Method for treating filter cake filter-press filtrate in polyolefin catalyst production

A polyolefin catalyst and treatment method technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Easy to block, reduce pollution, solve the effect of fast flux decay rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

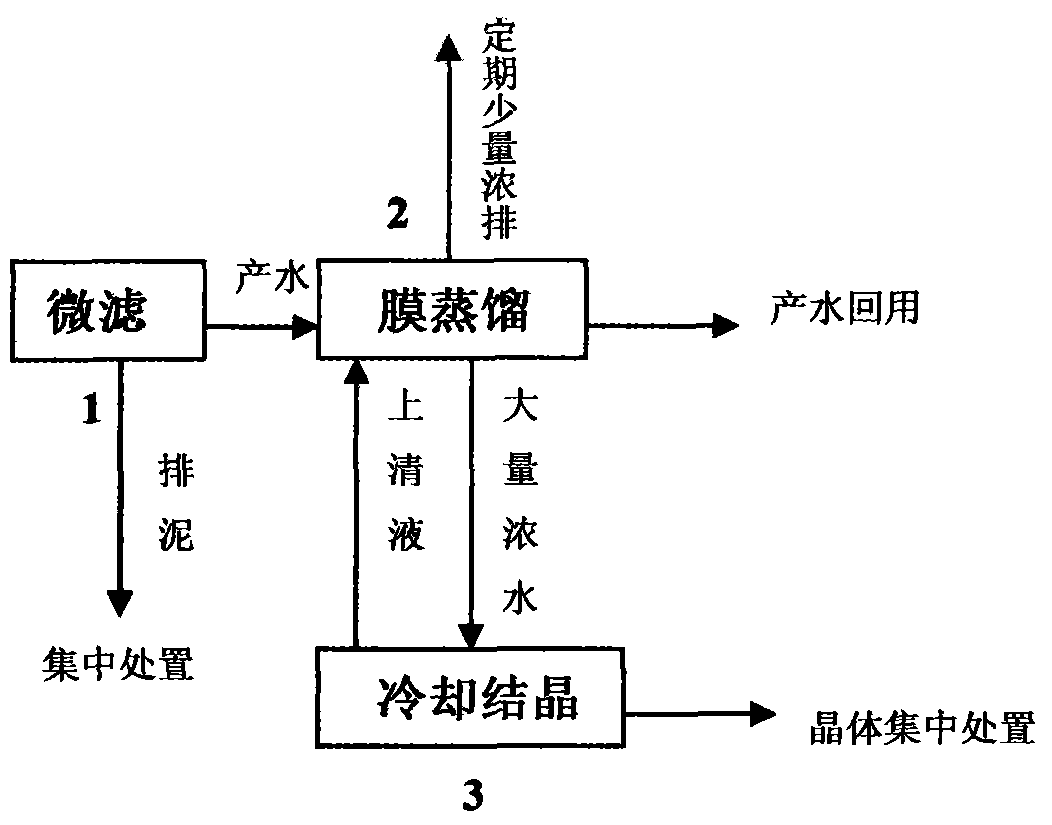

[0060] The main water quality characteristics of the filter cake press filtrate according to the present invention are: wastewater pH 3.35, conductance 235mS / cm, COD Cr About 4070mg / L, TOC 859mg / L, BOD 5 2110mg / L, TDS 239012mg / L, Ca 2+ 59mg / L, Mg 2+ 1027mg / L, Na + 93837mg / L, Cl - 162018mg / L, the organic matter is mainly a small amount of benzene series such as toluene. Processing flow such as figure 1 shown.

[0061] Step 1 uses submerged microfiltration to remove turbidity and suspended solids in wastewater, and the submerged microfiltration unit uses an external pressure polyvinylidene fluoride hollow fiber curtain membrane module. The operating conditions are: wastewater pH 3.35, wastewater temperature about 20°C, operating pressure about -0.02MPa. Under these operating conditions, the permeation flux of the microfiltration membrane is 50-100L / m 2 h, the turbidity of the product water is lower than 0.2NTU;

[0062] Step 2 Heat the microfiltration product water to ...

Embodiment 2

[0066] The main water quality characteristics of the filtrate after filter cake press filtration are the same as in Example 1.

[0067] Step 1 uses submerged microfiltration to remove turbidity and suspended solids in wastewater, and the submerged microfiltration unit uses an external pressure polyvinylidene fluoride hollow fiber curtain membrane module. The operating conditions are: wastewater pH 3.35, wastewater temperature about 20°C, operating pressure about -0.02MPa. Under these operating conditions, the permeation flux of the microfiltration membrane is 50-100L / m 2 h, the turbidity of the product water is lower than 0.2NTU;

[0068] Step 2 Heat the microfiltration product water to a specific temperature and then pump it into the membrane distillation system to concentrate. The membrane distillation unit adopts polyvinylidene fluoride hollow fiber membrane modules, and the membrane distillation type adopts internal pressure vacuum membrane distillation, that is, the shel...

Embodiment 3

[0072] The main water quality characteristics of the filtrate after filter cake press filtration are the same as in Example 1.

[0073] Step 1 uses submerged microfiltration to remove turbidity and suspended solids in wastewater, and the submerged microfiltration unit uses an external pressure polyvinylidene fluoride hollow fiber curtain membrane module. The operating conditions are: wastewater pH 3.35, wastewater temperature about 20°C, operating pressure about -0.02MPa. Under these operating conditions, the permeation flux of the microfiltration membrane is 50-100L / m 2 h, the turbidity of the product water is lower than 0.2NTU;

[0074] Step 2 Heat the microfiltration product water to a specific temperature and then pump it into the membrane distillation system for concentration. The membrane distillation unit adopts PTFE plate and frame membrane modules, and the membrane distillation type adopts vacuum membrane distillation, that is, the permeation side of the membrane mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com