Conductive heating type drying bin

A conduction heating and drying chamber technology, applied in the field of drying chambers, can solve the problems of increased power consumption of the drying chamber, difficulty in repairing, scrapped and unusable drying chambers, etc., and achieves the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

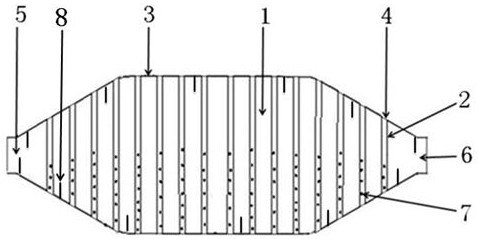

[0044] like figure 1 , figure 2 The drum-type conduction heating drying chamber shown includes a drying chamber 1 , a metal pipe 2 and a spiral blade 8 .

[0045] The drying bin 1 is a drum drying bin.

[0046]The bin body 3 of the drying bin 1 is made of metal plate, and the thickness of the bin body 3 is 2mm; the metal plate is processed into a drum drying bin through cutting, rolling, welding, polishing, inspection and the like.

[0047] The drying bin 1 has a feed port 5 and a discharge port 6 .

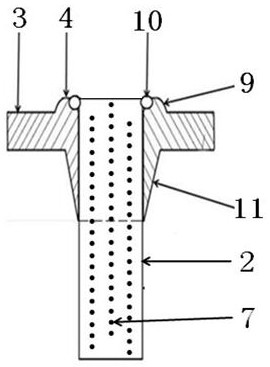

[0048] The chamber body 3 of the drying chamber 1 has a hot-melt hole 4, and the hot-melt hole 4 and the warehouse body 3 are integrated; The part protruding below the warehouse body 3 is the taper sleeve 11 . The aperture of the hot-melt hole 4 is the same as the diameter of the metal pipe 2; the distance between the hot-melt hole 4 and the hot-melt hole 4 is 60mm.

[0049] The hole length of the hot melt hole 4 is 8mm, and the hole diameter of the hot melt hole 4 is 25.4m...

Embodiment 2

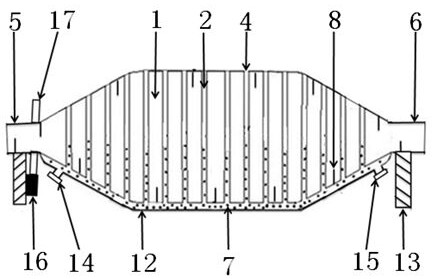

[0061] like Figure 4 , figure 2 The shown double-cone conductive heating drying chamber includes a drying chamber 1 , a metal pipe 2 and an exhaust pipe 18 .

[0062] like Figure 4 , figure 2 The structure of the double-cone conduction heating drying chamber shown in Embodiment 2 and the drum conduction heating drying chamber introduced in Embodiment 1 will not be repeated.

[0063] The drying bin 1 is a double-cone drying bin.

[0064] There is a feeding port 5 on the drying bin 1 .

[0065] The two ends of the metal pipe 2 are inserted into the upper and lower corresponding hot-melt holes 4 of the chamber body 3 of the drying bin 1, and the outside of the metal pipe 2 is tightly attached to the hole surface in the hot-melt hole 4, and the pipe of the metal pipe 2 The boss 9 of the head and the heat fusion hole 4 is fixedly welded as one, and it is airtight between the pipe head of the welded metal pipe 2 and the boss 9 of the heat fusion hole 4.

[0066] One end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com