Curing agent for deeply stirring mucky soil as well as preparation method and use method thereof

A muddy soil, deep mixing technology, applied in chemical instruments and methods, sludge treatment, solid waste management, etc., can solve the problems of long consolidation time, not widely recycled, low resource utilization, etc., to achieve Improving curing strength and impermeability, rapidly increasing curing strength, and improving curing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

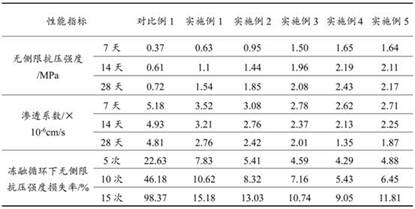

Examples

Embodiment 1

[0066] The present embodiment provides a kind of solidifying agent that is used for deep stirring muddy soil, and its formula is as follows:

[0067] 30 parts of PO42.5 cement, 40 parts of papermaking lime mud, and 30 parts of magnesium-based material waste.

[0068] Among them, the chemical composition of papermaking white mud is:

[0069] SiO 2 6.21wt%, K 2 O 3.16wt%, CaO 60.52wt%, MgO 0.85wt%, Al 2 o 3 5.25wt%, Fe 2 o 3 1.21wt%, LOI 22.8wt%.

[0070] The chemical composition of magnesium-based substrate waste is:

[0071] SiO 2 2.41 wt%, CaO 0.1 wt%, MgO 44.72wt%, SO 3 0.52wt%, LOI 52.25wt%.

Embodiment 2

[0073] The present embodiment provides a kind of solidifying agent that is used for deep stirring muddy soil, and its formula is as follows:

[0074] 30 parts of PO42.5 cement, 40 parts of papermaking lime mud, and 30 parts of magnesium-based material waste.

[0075] Among them, the chemical composition of papermaking white mud is:

[0076] SiO 2 6.21wt%, K 2 O 3.16wt%, CaO 60.52wt%, MgO 0.85wt%, Al 2 o 3 5.25wt%, Fe 2 o 3 1.21wt%, LOI 22.8wt%.

[0077] The chemical composition of magnesium-based substrate waste is:

[0078] SiO 2 10.15 wt%, CaO 6.56 wt%, MgO 41.82wt%, Al 2 o 3 4.05wt%, Fe 2 o 3 2.47wt%, LOI34.95%.

Embodiment 3

[0080] The present embodiment provides a kind of solidifying agent that is used for deep stirring muddy soil, and its formula is as follows:

[0081] 30 parts of PO42.5 cement, 40 parts of papermaking lime mud, and 30 parts of magnesium-based material waste.

[0082] Among them, the chemical composition of papermaking white mud is:

[0083] SiO 2 8.64wt%, CaO 50.18wt%, MgO 3.17wt%, Al 2 o 3 4.25wt%, Fe 2 o 3 2.81wt%, LOI30.95wt%.

[0084] The chemical composition of magnesium-based substrate waste is:

[0085] SiO 2 10.15wt%, CaO 6.56wt%, MgO 41.82wt%, Al 2 o 3 4.05wt%, Fe 2 o 3 2.47wt%, LOI34.95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com