Preparation method of lithium ion sieve adsorbent particles for liquid lithium resource extraction

An adsorbent, lithium ion technology, applied in the field of lithium ion sieve adsorbent particle preparation, can solve the problems of poor water permeability of the adsorbent particle matrix material, slow adsorption process, reduced adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

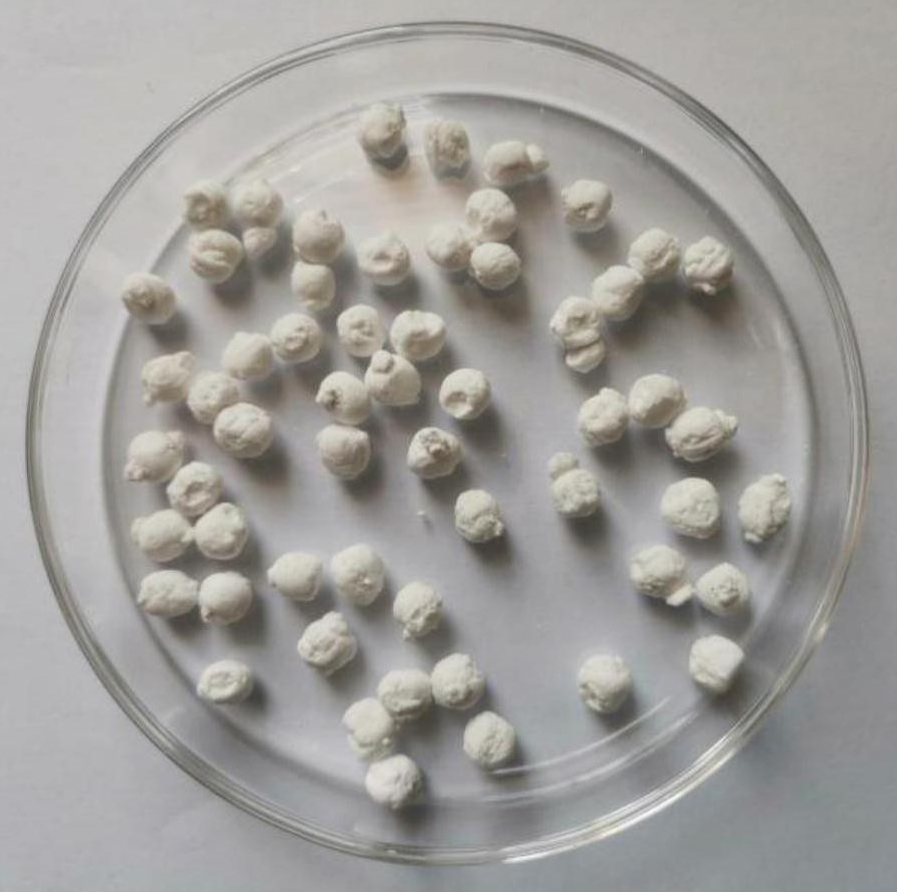

Image

Examples

Embodiment 1

[0074] A kind of adsorbent particles for liquid lithium resource extraction is carried out in the following manner:

[0075] Step 1, spinel-type Li 4 Ti 5 o 12 Dry it at 80°C, and crush it with a high-speed pulverizer to a particle size of 800-1000 mesh to obtain an adsorbent powder.

[0076] Step 2, dissolving polyvinyl alcohol with an alcoholysis degree of 85% in water to prepare a 10 wt% polyvinyl alcohol aqueous solution.

[0077] Step 3: Mix the polyvinyl alcohol aqueous solution and the adsorbent powder at a mass ratio of 3:1, and use a three-roll mill to mix evenly.

[0078] Step 4: Add a certain amount of the first crosslinking agent aqueous solution to the mixture obtained in step 3, wherein the mass ratio of the first crosslinking agent aqueous solution to the mixture and the first crosslinking agent solution is 1:2. The composition of the first crosslinking agent aqueous solution is 3wt% boric acid, 1wt% borax, 1wt% aluminum chloride, 1wt% calcium chloride, and ...

Embodiment 2

[0085] A kind of adsorbent particles for liquid lithium resource extraction is carried out in the following manner:

[0086] Step 1, spinel-type Li 1.6 mn 1.6 o 4 Dry it at 80°C, and crush it to a particle size of 800-1000 mesh by a high-speed pulverizer to obtain adsorbent powder;

[0087] Step 2, dissolving polyvinyl alcohol with a degree of alcoholysis of 85% in water to prepare a 10wt% solution

[0088] Step 3, dissolving sodium polyacrylate with an average molecular weight of 1.25 million in water to prepare a solution with a concentration of 3 wt%.

[0089] Step 4: Mix the polymer aqueous solutions prepared in Step 2 and Step 3 at a mass ratio of 10:1, and use a high-viscosity stirring paddle to mix evenly to obtain a high-viscosity polymer mixed solution.

[0090] Step 5: Add the adsorbent powder in step 1 to the high-viscosity polymer mixture solution in step 4 and mix in a mass ratio of 1:3, stir or grind until uniform.

[0091] Step 6: Add a certain amount of th...

Embodiment 3

[0096] A kind of adsorbent particles for liquid lithium resource extraction is carried out in the following manner:

[0097] Step 1, spinel-type Li 4 Ti 5 o 12 The adsorbent powder is dried at 80°C and crushed by a high-speed pulverizer to a particle size of 800-1000 mesh to obtain the adsorbent powder;

[0098] Step 2, dissolving polyvinyl alcohol with a degree of alcoholysis of 85% in water to prepare a 10wt% solution

[0099] Step 3, dissolving polyacrylic acid with an average molecular weight of 1.25 million in water to prepare a solution with a concentration of 4 wt%.

[0100] Step 4, dissolving sodium alginate in water to prepare a 3wt% solution

[0101] Step 5: Mix the polymer aqueous solution prepared in Step 2, Step 3, and Step 4 in a mass ratio of 10:1:1, and use a high-viscosity stirring paddle to mix evenly to obtain a high-viscosity polymer mixed solution.

[0102] Step 6: Add the adsorbent powder in step 1 to the high-viscosity polymer mixture solution in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com