Steel wire mesh framework corrugated pipe and preparation method thereof

A steel mesh and corrugated pipe technology is applied in the field of steel mesh skeleton corrugated pipes and their preparation, which can solve the problems of affecting the water supply and drainage function of pipes, collapse and deformation above the pipes, and consume manpower and material resources. Quantity, tensile strength, performance and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

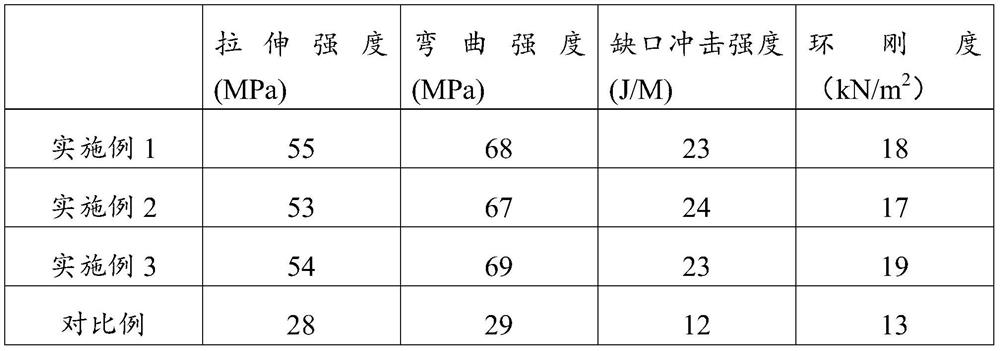

Examples

Embodiment 1

[0024] A corrugated pipe with a steel mesh skeleton, the corrugated pipe sequentially includes a polyethylene inner pipe, a first hot-melt adhesive layer, a steel mesh layer, a second hot-melt adhesive layer and a polyethylene outer pipe from the inside to the outside, the polyethylene inner pipe The tube and the polyethylene outer tube are composed of the following raw materials in parts by weight: 65 parts of polyethylene, 5 parts of polyoxyethylene, 15 parts of ethylene-vinyl acetate copolymer, 4 parts of modifier, 2 parts of silicon carbide powder, modified 3 parts of talcum powder, 5 parts of calcium stearate, and 5 parts of epoxy resin.

[0025] The polyethylene inner tube and polyethylene are corrugated in appearance, the first hot melt adhesive layer and the second hot melt adhesive layer are spiral and sandwich the steel mesh layer in the middle, and the thickness of the steel mesh layer is 1 mm.

[0026] The modifying agent comprises 30 parts of carbon fiber, 50 part...

Embodiment 2

[0033] A corrugated pipe with a steel mesh skeleton, the corrugated pipe sequentially includes a polyethylene inner pipe, a first hot-melt adhesive layer, a steel mesh layer, a second hot-melt adhesive layer and a polyethylene outer pipe from the inside to the outside, the polyethylene inner pipe The tube and the polyethylene outer tube are composed of the following raw materials in parts by weight: 85 parts of polyethylene, 12 parts of polyethylene oxide, 35 parts of ethylene-vinyl acetate copolymer, 12 parts of modifier, 6 parts of silicon carbide micropowder, modified 12 parts of talcum powder, 15 parts of calcium stearate, and 15 parts of epoxy resin.

[0034] The polyethylene inner tube and polyethylene are corrugated in appearance, the first hot melt adhesive layer and the second hot melt adhesive layer are spiral and sandwich the steel mesh layer in the middle, and the thickness of the steel mesh layer is 5 mm.

[0035] The modifying agent comprises 45 parts of carbon f...

Embodiment 3

[0042] A corrugated pipe with a steel mesh skeleton, the corrugated pipe sequentially includes a polyethylene inner pipe, a first hot-melt adhesive layer, a steel mesh layer, a second hot-melt adhesive layer and a polyethylene outer pipe from the inside to the outside, the polyethylene inner pipe The tube and the polyethylene outer tube are composed of the following raw materials in parts by weight: 70 parts of polyethylene, 10 parts of polyethylene oxide, 25 parts of ethylene-vinyl acetate copolymer, 8 parts of modifier, 4 parts of silicon carbide micropowder, modified 9 parts of talcum powder, 10 parts of calcium stearate, and 10 parts of epoxy resin.

[0043] The polyethylene inner tube and polyethylene are corrugated in appearance, the first hot melt adhesive layer and the second hot melt adhesive layer are spiral and sandwich the steel mesh layer in the middle, and the thickness of the steel mesh layer is 3mm.

[0044]The modifying agent comprises 40 parts of carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com