Hydrochloric acid purification system and process

A purification system and hydrochloric acid technology, which is applied in the field of hydrochloric acid purification system and technology, can solve the problems of no research reports, poor quality of hydrochloric acid, suffocating odor, etc., and achieve the effect of low equipment investment cost, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

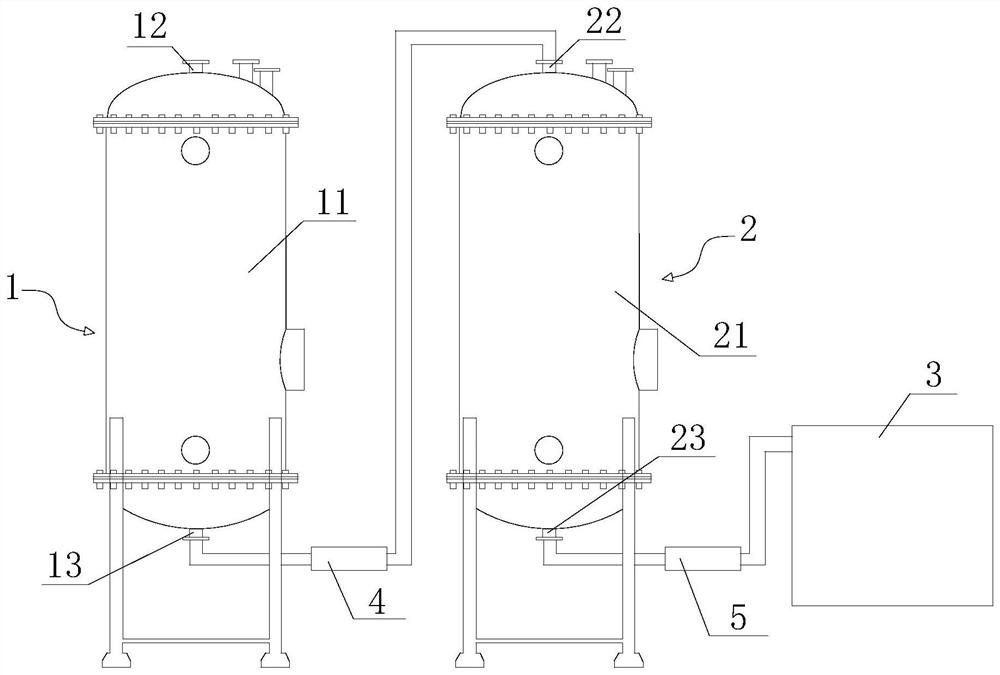

[0047] like figure 1 Shown, a kind of hydrochloric acid purification system comprises dechlorination device 1, iron removal device 2 and recovery tank 3 connected in sequence;

[0048] The chlorine removal device 1 includes a chlorine removal tank 11 filled with activated carbon, and the top and bottom of the chlorine removal tank 11 are respectively provided with a chlorine removal liquid inlet 12 and a chlorine removal liquid outlet. Port 13, the dechlorination liquid inlet 12 is used to introduce hydrochloric acid into the dechlorination tank body 11;

[0049] The iron removal device 2 includes an iron removal tank 21 filled with resin, and the top and bottom of the iron removal tank 21 are respectively provided with an iron removal liquid inlet 22 and an iron removal liquid outlet 23. The iron removal liquid inlet 22 and the chlorine removal liquid outlet 13 are connected by a pipeline, and a first filter 4 is arranged on the pipeline,

[0050] The recovery tank 3 is con...

Embodiment 2

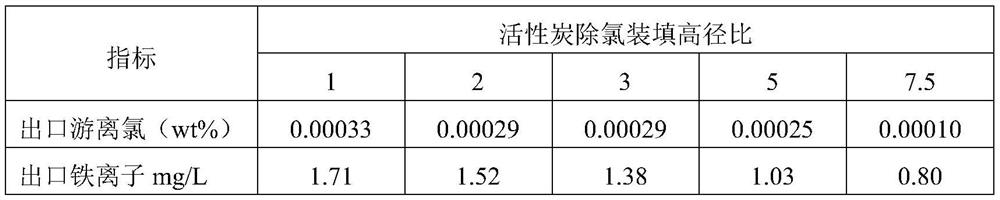

[0062] Since the free chlorine index of the purification system is a key index compared with the iron ion index, research on it is focused. In this example, the purification system described in Example 1 is used to verify the effect of different filling heights of activated carbon on the purification effect, and the aspect ratio of the resin is 7.5.

[0063] The concentration of imported hydrochloric acid is 30.28%, the concentration of free chlorine is 0.00185%, and the concentration of iron ions is 24.16mg / L. The activated carbon aspect ratio and removal effect are shown in Table 1:

[0064] Table 1

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com