Preparation method of lanthanum modified activated carbon adsorption material

A technology of activated carbon adsorption and powdered activated carbon, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low selectivity, low recovery rate, and low adsorption efficiency, and achieve High selectivity, high adsorption efficiency, and the effect of improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] DETAILED DESCRIPTION OF THE INVENTION First: The preparation method of ruthenium-modified active carbon suction material is achieved as follows:

[0031] First, hexahydrochloride and 200 megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload megadownload

[0032] Second, the mixed solution A is dispersed in the propanol, and then the pH range is adjusted with 1 M NaOH solution, stirred for 30 to 60 min, and the mixed solution B is obtained.

[0033] Third, the mixed solution B is transferred to a polytexfluoroethylene high pressure reaction kettle 4 to 6 h, and the reaction product is centrifted, and then freeze dry after washing, i.e., the preparation of ruthenium-modified active carbon suction materials.

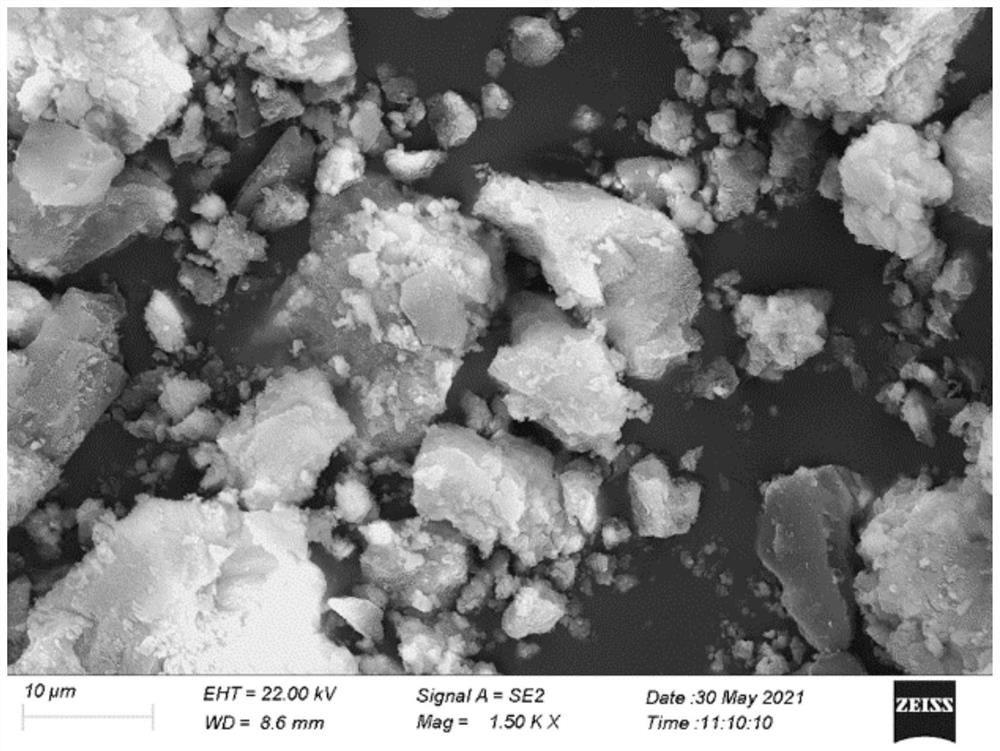

[0034] In the step of the present embodiment, a 200 mesh powder activated carbon is employed, and the prepared final product is a ruthenium-modified powder activated carbon (LA-AC); if a particul...

specific Embodiment approach 2

[0035] DETAILED DESCRIPTION OF THE INVENTION The present embodiment is different from the specific embodiment, and hexahydrate chloride = 0.1 to 0.3 mol / L in a mixed solution A. Other steps and parameters are identical to those of the specific embodiments.

specific Embodiment approach 3

[0036] DETAILED DESCRIPTION OF THE INVENTION 3: The present embodiment differs from the specific embodiment, and the amount of powder activated carbon is 0.1 to 0.4 g; the amount of particulate activated carbon is 0.1 to 0.4 g; the amount of ultrapure water is 30 ~ 50ml. Other steps and parameters are identical to those of the specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com