A prefabricated phase change thermal storage energy-saving wall panel

A phase-change heat storage and prefabricated technology, which is applied to walls, buildings, building components, etc., can solve the problems of time-consuming and laborious installation and disassembly, poor heat storage and energy saving effect, and waste of plates, so as to achieve convenient construction and improve heat storage. Energy saving effect, effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

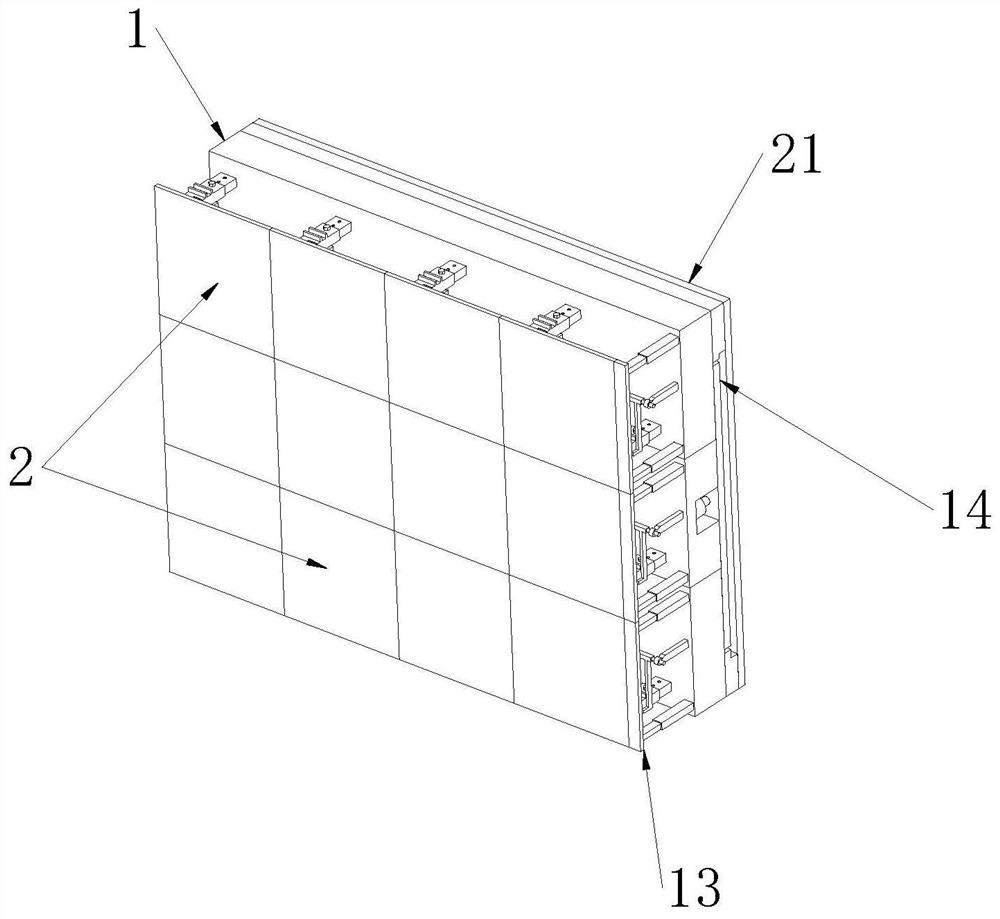

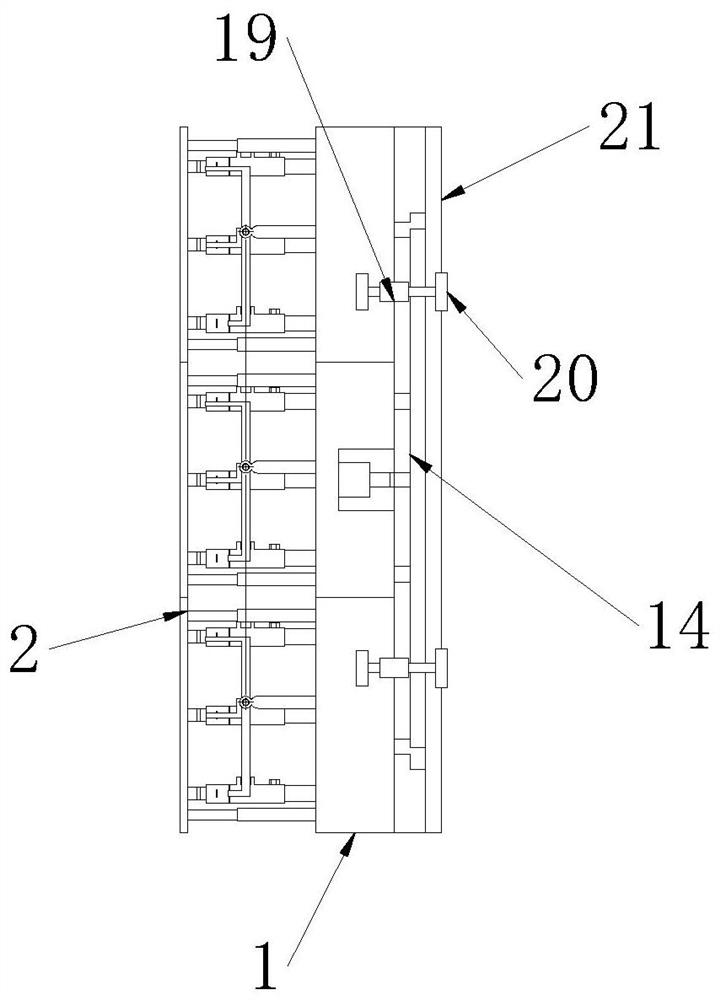

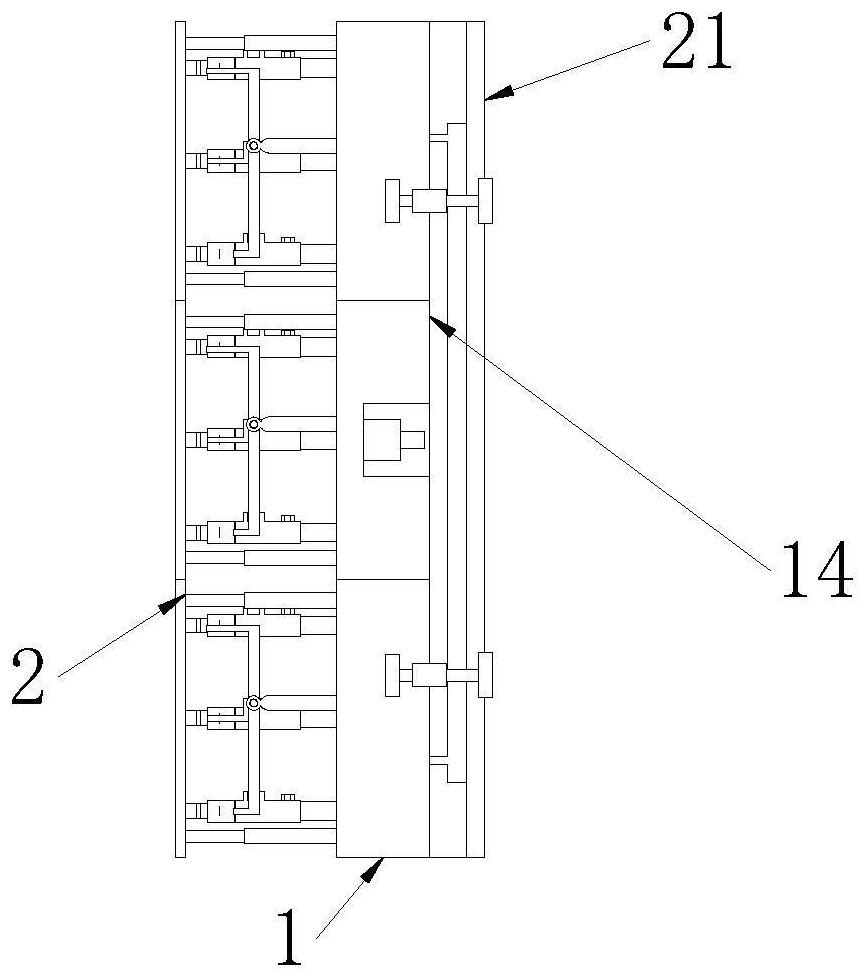

[0033] Example: such as Figure 1-3 As shown, a prefabricated phase-change heat storage energy-saving wall panel includes a load-bearing wall 1, and: the load-bearing wall 1 is located on the indoor side and is a phase-change wall panel composed of several phase-change panels 2, wherein, in A plurality of bushings 3 are installed on the load-bearing wall 1, and each phase-change plate 2 is equipped with an insert 4 on one side close to the phase-change wall plate, and each phase-change plate 2 is perpendicular to the direction of the load-bearing wall 1 through the insert 4 and corresponds to The casing 3 is plugged in, and each casing 3 is equipped with a limiter and an adjustment rod 7 connected with the limiter. The adjustment rod 7 drives the limiter to move, and the control sleeve 3 is locked with the corresponding plug 4 or unlock; load-bearing wall 1 is located at the outdoor side, and is composed of several groups of thermal insulation panels, each group of thermal ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com