Ultra-large solid wood cylinder mounting structure and mounting process thereof

An installation structure, super-large technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of high stress at the corners of components, flatness and radian not meeting the requirements, difficult construction, etc., to achieve convenient maintenance Disassembly, easy adjustment and installation, good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

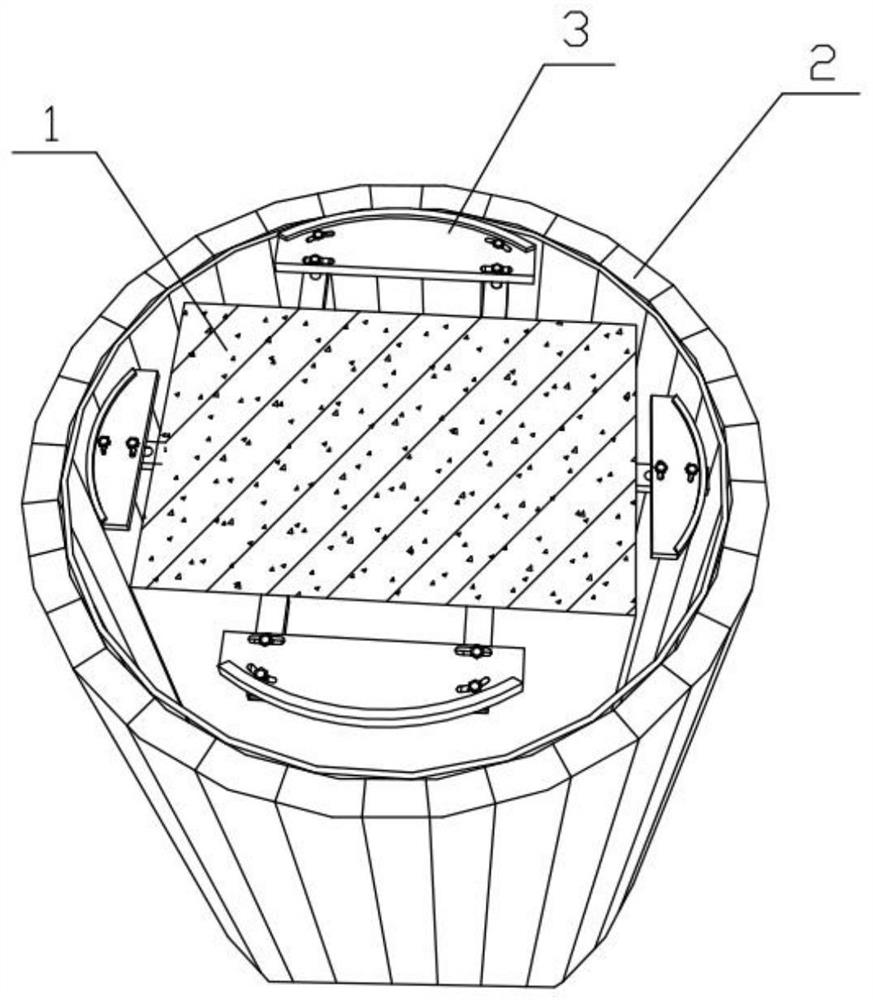

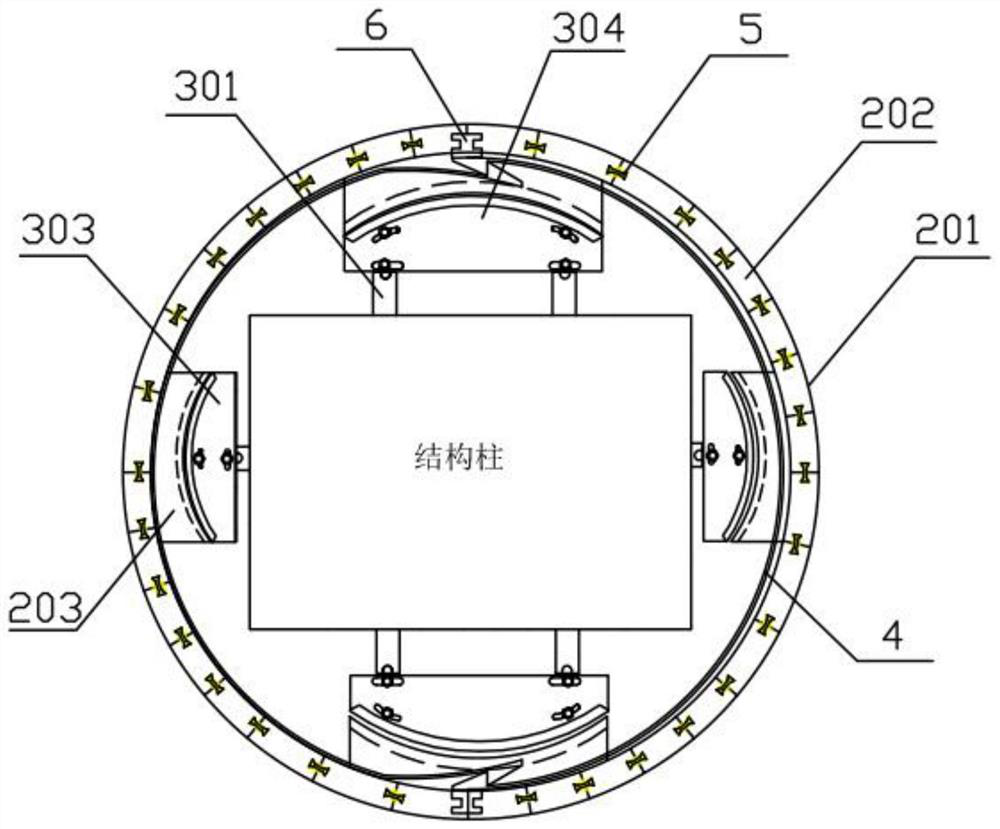

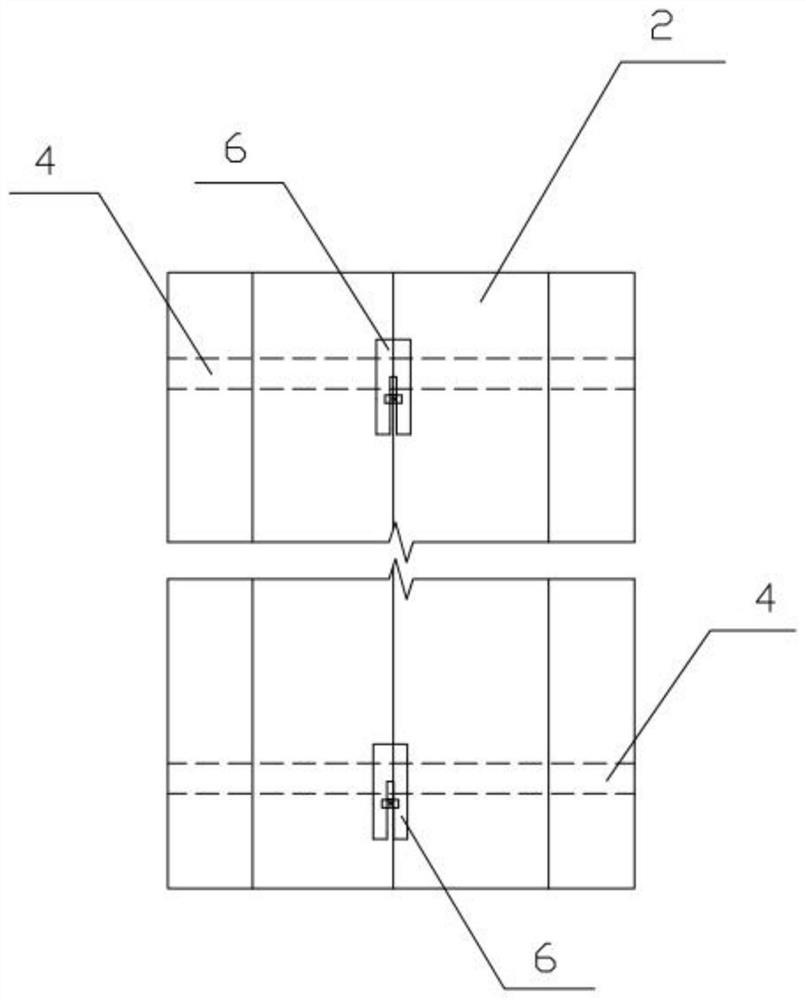

[0037] The invention will be further described below in conjunction with the accompanying drawings of the description.

[0038] like Figure 1-9 As shown, the super-large solid wood column installation structure includes structural column 1, solid wood column 2, solid wood column split 201, solid wood column components 202, hanging board 203, scalable and adjustable cross-direction beam sleeper structure 3, and embedded anchors Board 301, extended hanging column 302, small curved crossties 303, large curved crossties 304, leading beam crossties 305, horizontal columns 306, hidden reverse hoop structure 4, reverse hoop 401, forward hoop 402 , Forward triangular joint 403, Reverse triangular joint 404, Bow tie double folded curved surface tenon structure 5, Curved surface tenon member main body 501, Dovetail tenon 502, Folded tooth pattern 503, Detachable closing structure 6, I-shaped piece 601, screw 602, opening 603, draw-in groove one 604, draw-in groove two 605, jacking rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com