Construction method of foam concrete emergency lane

A foamed concrete and risk-avoidance lane technology, which is applied in the directions of roads, roads, climate change adaptation, etc., can solve the problems of insufficient space, large floor space, and difficulty in setting up the safety-avoidance lane, so as to ensure dryness and looseness and reduce construction. Length, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

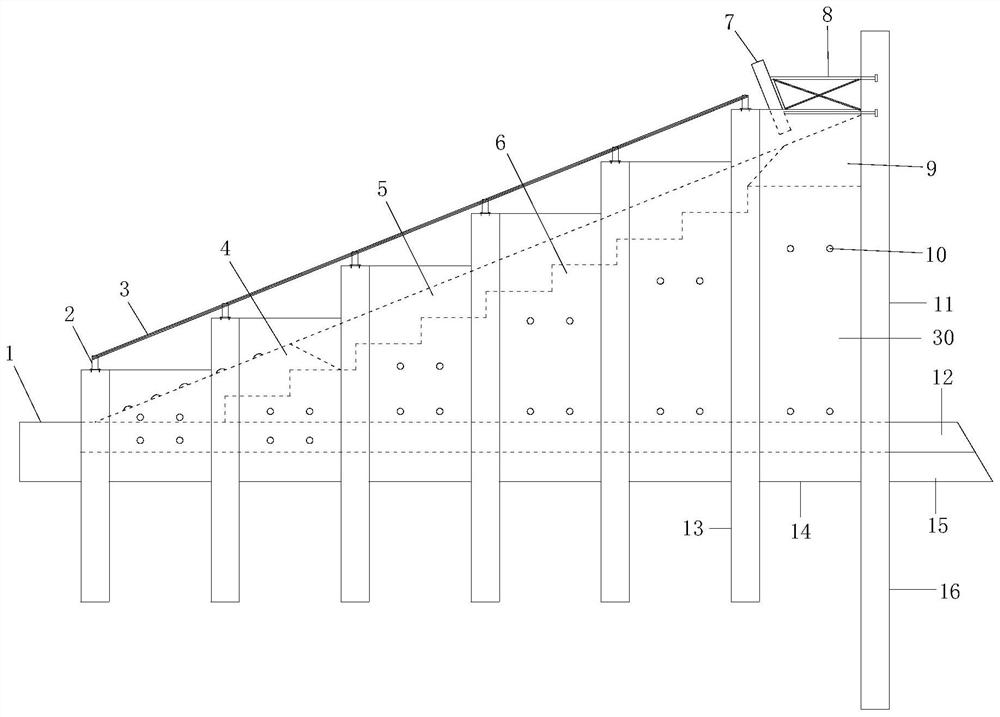

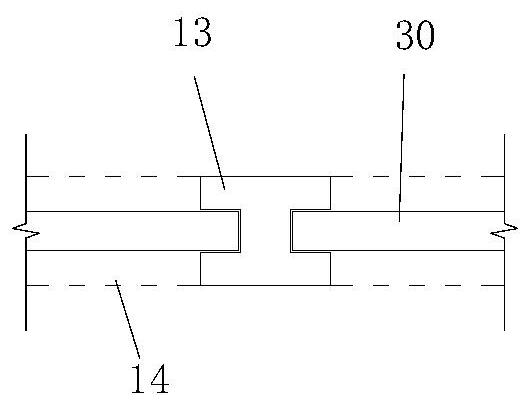

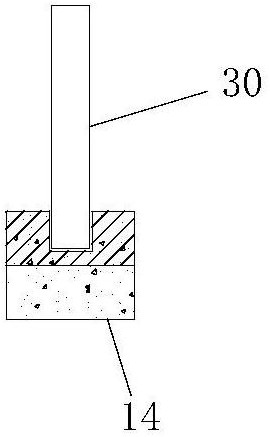

[0046] The foam concrete safe-haven lane includes a road guide section 1, a front buffer deceleration section 4, a sand layer deceleration section 5 in the middle, a top anti-collision section 9, a service lane 31 and a strong rebound rubber net 32; the road guide section 1 is connected to The traffic main line and the front buffer deceleration section 4, the front buffer deceleration section 4 is connected to the middle sand layer deceleration section 5, the middle sand layer deceleration section 5 is connected to the top anti-collision section 9, and the service lane 31 and the middle sand layer deceleration section 5 are Parallel to the section, the bottom of the escape lane is provided with a compacted plain soil layer 15, a gravel layer 12 and foam concrete 6, prefabricated H-shaped piles 13 are arranged on both sides of the escape lane, and end piles are arranged at the end of the escape lane 16. End columns 11 and anti-collision walls 17, a strip foundation 14 is set bet...

Embodiment 2

[0055] The construction method of described foam concrete escape lane, comprises the following steps:

[0056] 1) Level the site in the construction area of the escape lane, determine the specific construction location according to the measurement and setting out, and first carry out the construction of the rammed plain soil layer 15 at the bottom. This area is located at the bottom of the strip foundation 14, and the rammed area should exceed the strips on both sides. Foundation 14 a certain range;

[0057] 2) Integrated construction of end pile 16, end column 11 and reinforced concrete anti-collision wall 17: drilling holes on both sides of the end of the escape lane, lowering the reinforcement cage to form end pile 16, and then lapping and binding steel bars on the top of end pile 16 Pouring to form the end column 11, and reserve a groove on the inner side of the end column 11 to facilitate the insertion of the prefabricated steel-concrete panel 30 in the later stage, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com