Ceramic digital ink with matte carving effect and application thereof

A digital and ink technology, applied in the field of new materials for ceramics, can solve problems such as difficulties, and achieve the effect of low production cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

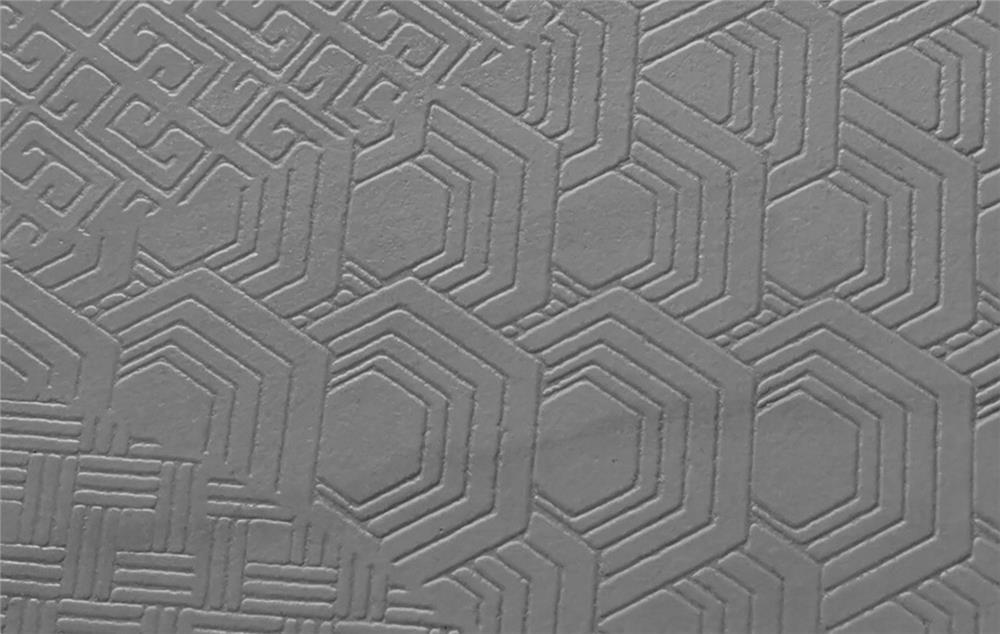

Image

Examples

preparation example Construction

[0036] A method for preparing a digital ink with a matte engraving effect, the composition of the digital ink is as described in the first aspect of the present invention, including:

[0037] Crush the powder and mix well;

[0038] The pulverized powder, solvent and additives are mixed, further ground, filtered and packaged to obtain a digital ink with a matte engraving effect.

[0039] A third aspect of the present invention provides:

[0040] A ceramic with a matte engraving effect, the digital ink described in the first aspect of the present invention is used in the preparation process.

[0041] Below in conjunction with example, further illustrate the technical scheme of the present invention.

Embodiment 1

[0049] The digital ink of matte engraving effect is prepared according to the following formula, and the digital ink of matte engraving is composed of the following components according to the mass percentage:

[0050] Albite 6%

[0051] Wollastonite 5%

[0052] Limestone 2%

[0054] Quartz 1%

[0055] Corundum 10%

[0056] High Calcium Zinc Frit 10%

[0057] Polyamide dispersant 10%

[0058] Defoamer BYK-066N 0.05%

[0059] Ester solvent 53.95%;

[0060] Wherein the inorganic chemical components of the high-calcium zinc-containing frit are calculated as follows in parts by weight of oxides:

[0061] CaO 19%

[0062] Al 2 o 3 6%

[0063] MgO 2.5%

[0064] K 2 O 3%

[0065] ZnO 6.5%

[0066] SiO 2 63%

[0067] The ester solvent is a combination of dioctyl adipate, diisooctyl triethylene glycol and butyl glycol acetate.

[0068]The viscosity of the digital ink that controls the matte engraving effect is 15-25cp at 40°C, the su...

Embodiment 2

[0070] The digital ink of matte engraving effect is prepared according to the following formula, and the digital ink of matte engraving is composed of the following components according to the mass percentage:

[0071] Albite 7%

[0072] Wollastonite 7%

[0073] Limestone 2%

[0075] Quartz 2%

[0076] Corundum 12%

[0077] High Calcium Zinc Frit 12%

[0078] Dispersant 10%

[0079] Defoamer BYK-052 0.05%

[0080] Ester solvent 44.95%;

[0081] Wherein the inorganic chemical components of the high-calcium zinc-containing frit are calculated as follows in parts by weight of oxides:

[0082] CaO 19%

[0083] Al 2 o 3 6%

[0084] MgO 2.5%

[0085] K 2 O 3%

[0086] ZnO 6.5%

[0087] SiO 2 63%

[0088] Wherein, the dispersant is a combination of a polyamide dispersant and a polyester hyperdispersant; the ester solvent is a combination of isooctyl cocoate and isopropyl laurate.

[0089] The viscosity of the digital ink that contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com