Array electrofluid jet printing control method and device for inhibiting jet flow inclination

A control method and electro-fluid technology, applied in printing and other directions, can solve the problems of lack of mature control strategy and control system, prone to jet tilt, etc., and achieve the effect of reducing jet tilt phenomenon, suppressing jet tilt and reducing influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

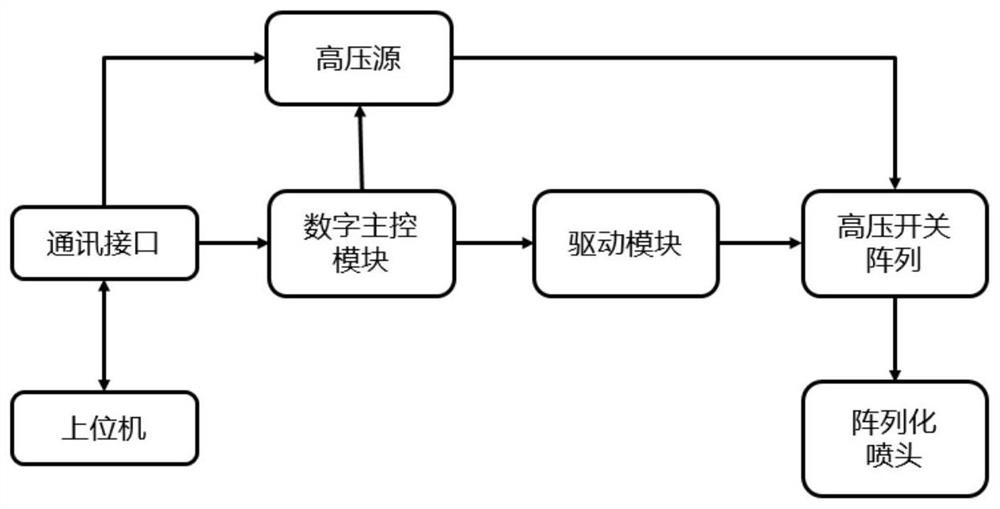

[0041] The arrayed electrofluid jet printing device includes an arrayed nozzle, a high-voltage source, a high-voltage switch array, a drive module, a digital main control module, and a host computer, such as figure 2 shown, where:

[0042] The arrayed nozzle adopts a protruding microneedle structure, including 8 nozzles with independent lead-out electrodes, with a spacing of 1mm. The power supply method is directly powered by the liquid, and the turn-on voltage is about 1800V.

[0043] The high-voltage source is divided into two parts: the working signal source and the control signal source. The working signal source is a combination of a signal generator and a high-voltage amplifier, and the control signal source is a high-voltage DC source.

[0044] The high-voltage switch array is composed of 8 groups of high-voltage dry reed relays connected in parallel, which correspond to 8 nozzles one by one, and each group contains two high-voltage switches, in which the output end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com