Master batch indirect cooling device

A technology of cooling device and masterbatch, which is applied in the direction of coating, etc., can solve the problems of excessive equipment occupation area, excessive moisture in masterbatch, and easy pollution of masterbatch, so as to reduce the occupation area and save power resources , Improve the effect of movement fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

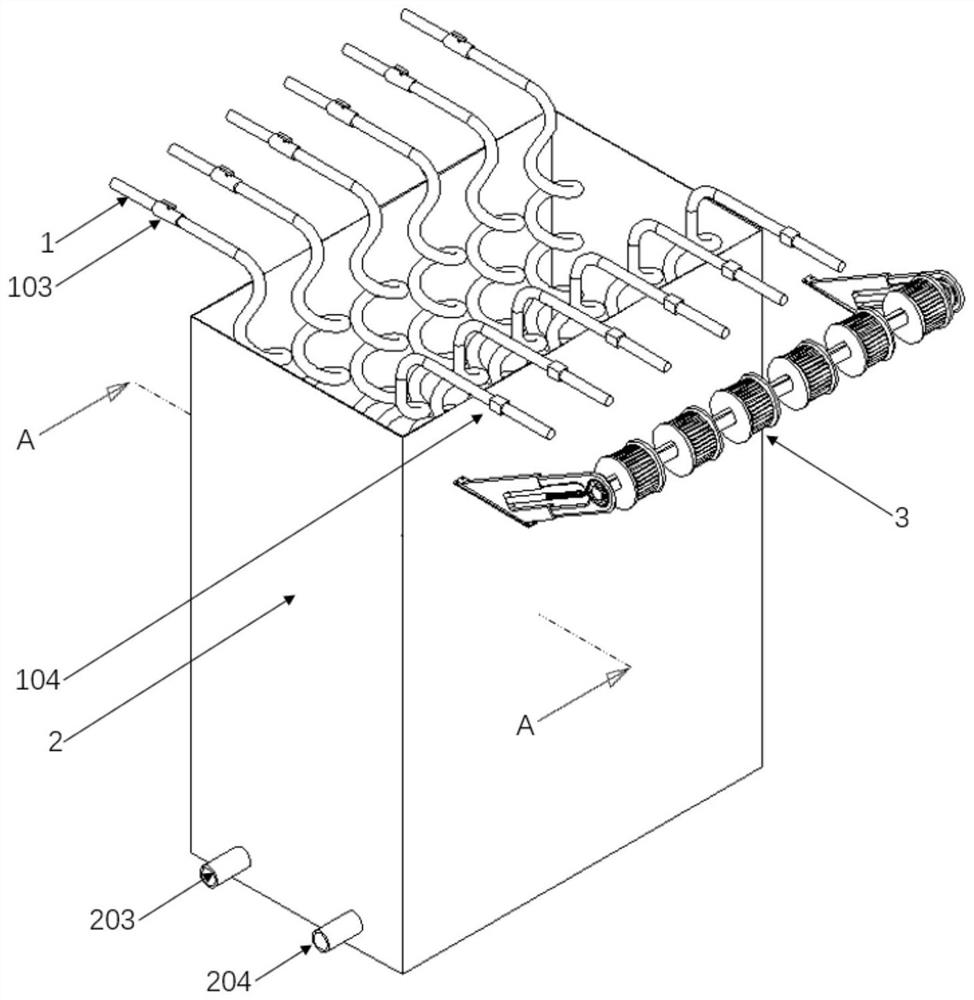

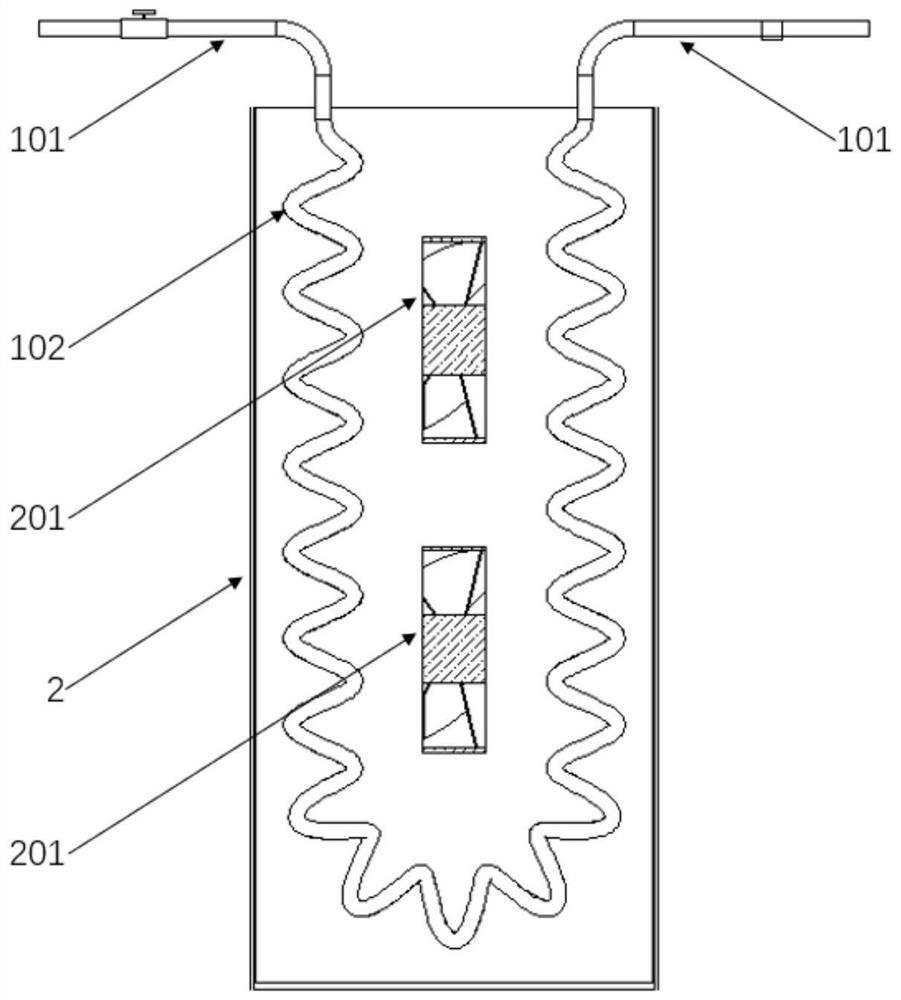

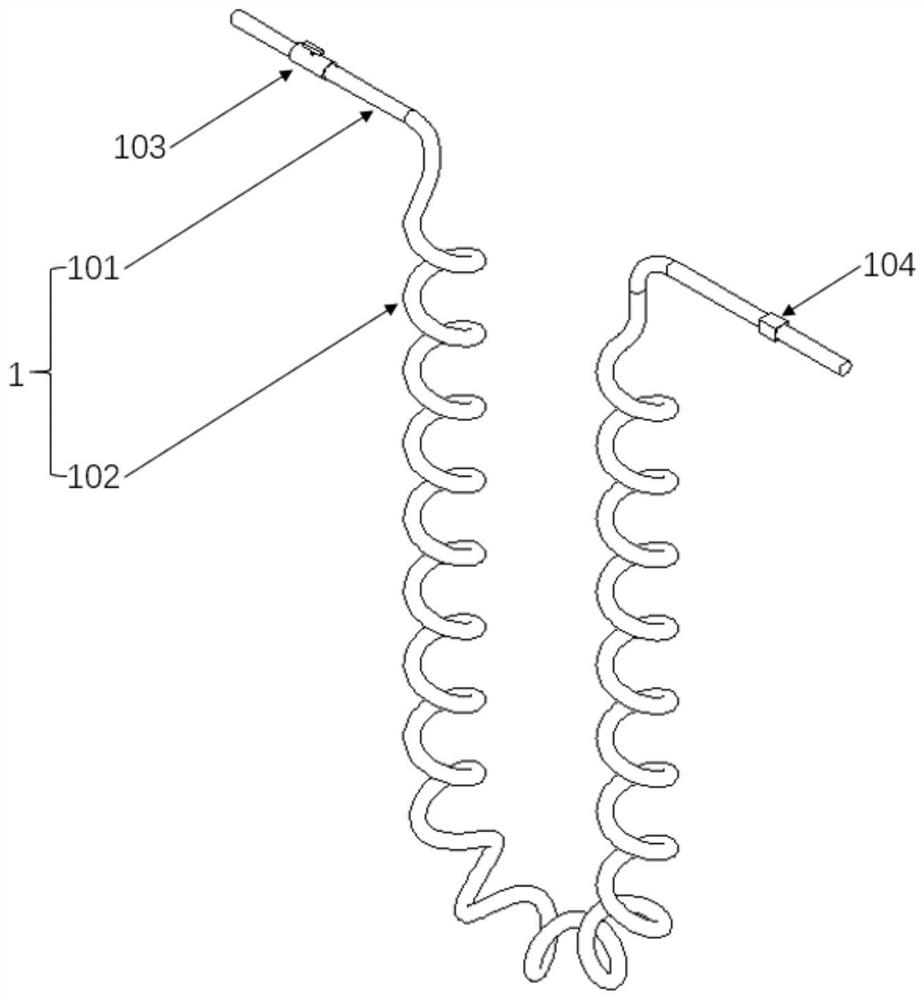

[0027] see Figure 1~Figure 7 , an indirect cooling device for masterbatch, including several heat pipes 1, coolant tank 2 and traction wheel set 3, the heat pipe 1 includes a straight pipe section 101 and a spiral pipe section 102, and the straight pipe section 101 and the spiral pipe section 102 are integrated and seamless Connection structure, the coolant tank 2 is filled with coolant and is provided with a circulation pump 201, the circulation pump 201 is used to speed up the circulation of the coolant in the coolant tank 2, so that the temperature of each area in the coolant tank 2 is uniform; the spiral pipe section 102 is submerged in the cooling liquid. Both ends of the spiral pipe section 102 are straight pipe sections 101. One end of the straight pipe section 101 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com