Fur shearing device

A hair clipper and main body technology, which is applied in the field of hair clippers, can solve the problems of poor heat dissipation and complex cutter head structure, achieve good heat dissipation function, avoid increased battery energy loss, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

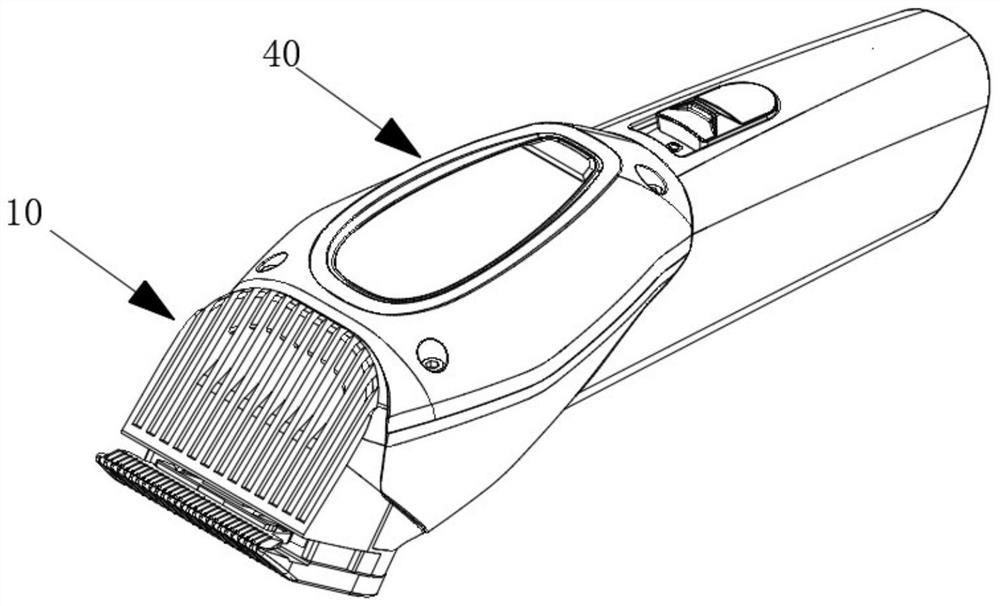

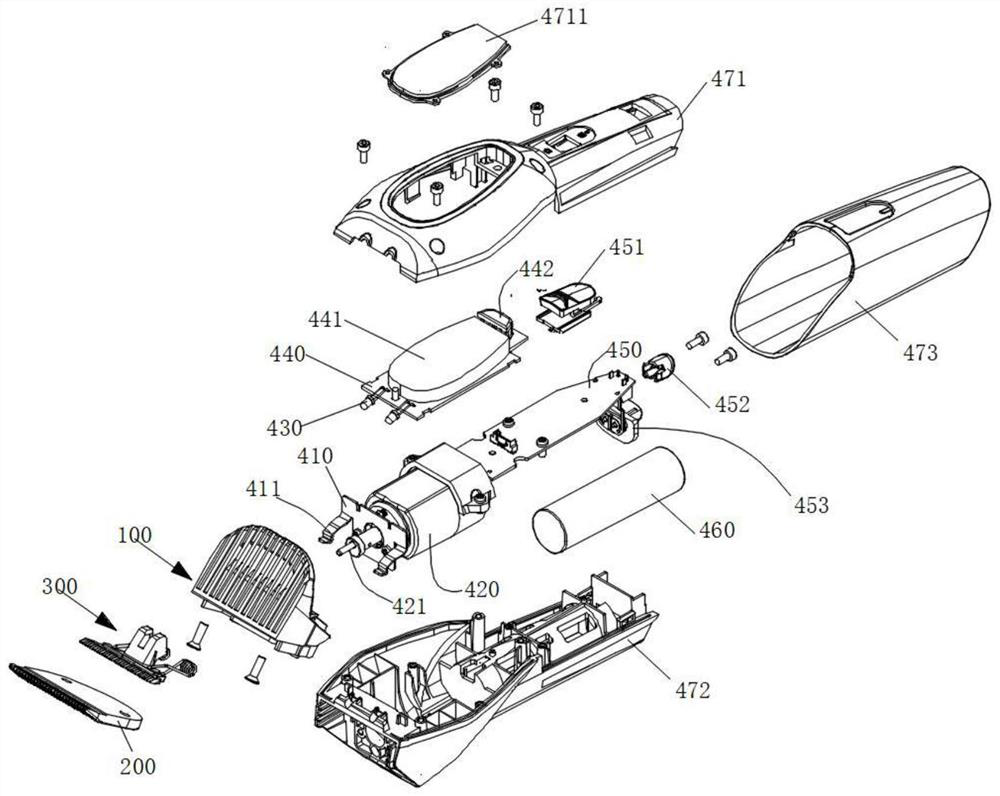

[0068] refer to Figure 1 to Figure 6 The hair clipper of this embodiment includes a main body 40 and a cutter head assembly 10 fixed on the front side of the main body 40 .

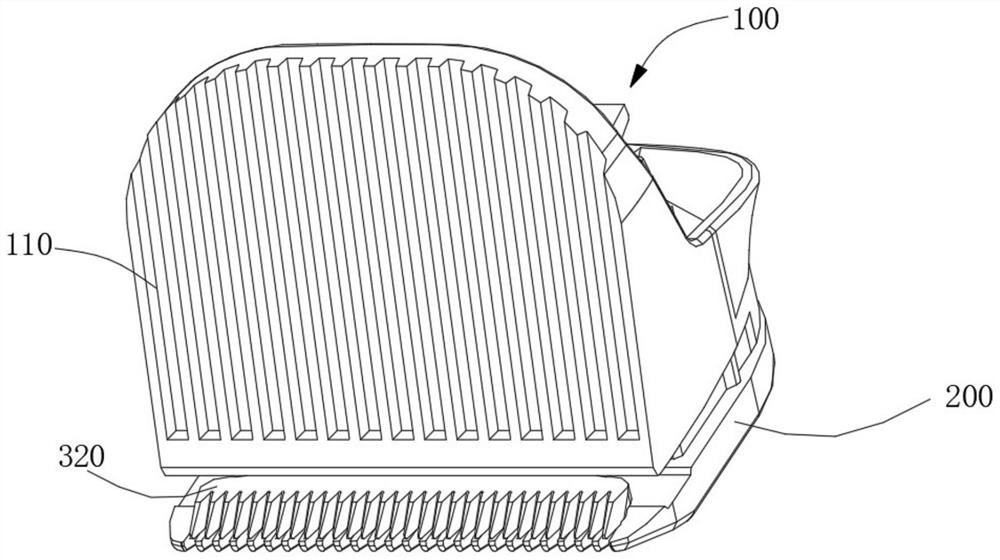

[0069] Such as Figure 3 to Figure 6 As shown, the cutter head assembly 10 includes a heat sink 100 , a stationary blade 200 and a moving blade assembly 300 .

[0070] The heat sink 100 includes a heat sink 110 and a mounting structure 120 . Wherein, the heat dissipation plate 110 is plate-shaped, and its upper end is inclined toward the main body 40 , that is, it is inclined backward. A heat dissipation structure and a light transmission structure are provided on the front surface of the heat dissipation plate 110 . In practical application, in order to improve the heat dissipation effect, the heat dissipation structure may be a wavy or elongated heat sink. Open slots can be arranged between the heat sinks to form a light-transmitting structure.

[0071] The left and right side walls of the cooling...

Embodiment 2

[0104] On the basis of Embodiment 1, the hair clipper of this embodiment is proposed, and the display module in Embodiment 1 is replaced by a working status indicator light and a blade life indicator light.

[0105] refer to Figure 7 and Figure 8 , in this embodiment, the working status indicator light includes a power indicator light 482 and a working mode indicator light 483 . The power indicator light 482 and the blade life indicator light 481 are arranged on the front side of the light control circuit board 440 , and the working mode indicator light 483 is arranged on the rear side of the light control circuit board 440 . Wherein, the working mode indicator light 483 includes a plurality of indicator lights arranged side by side, and indicates different working modes of the hair clipper according to the number of lighted indicator lights, for example, when there are fewer lighted indicator lights, it represents a silent working mode When all the indicator lights of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com