Position correction device and using method thereof

A calibration device and a technology of the calibration department, which is applied in the positioning of the logistics process, and in the field of logistics, can solve the problems of system error, inability to effectively find a space position of the workpiece, and inability to realize automatic clamping of the workpiece at one time, so as to achieve accurate grasping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the content of the invention will be described in detail in conjunction with the accompanying drawings. Obviously, the following descriptions are some typical embodiments of the present invention. For those of ordinary skill in the art, without paying On the premise of creative work, other solutions can also be obtained according to these embodiments.

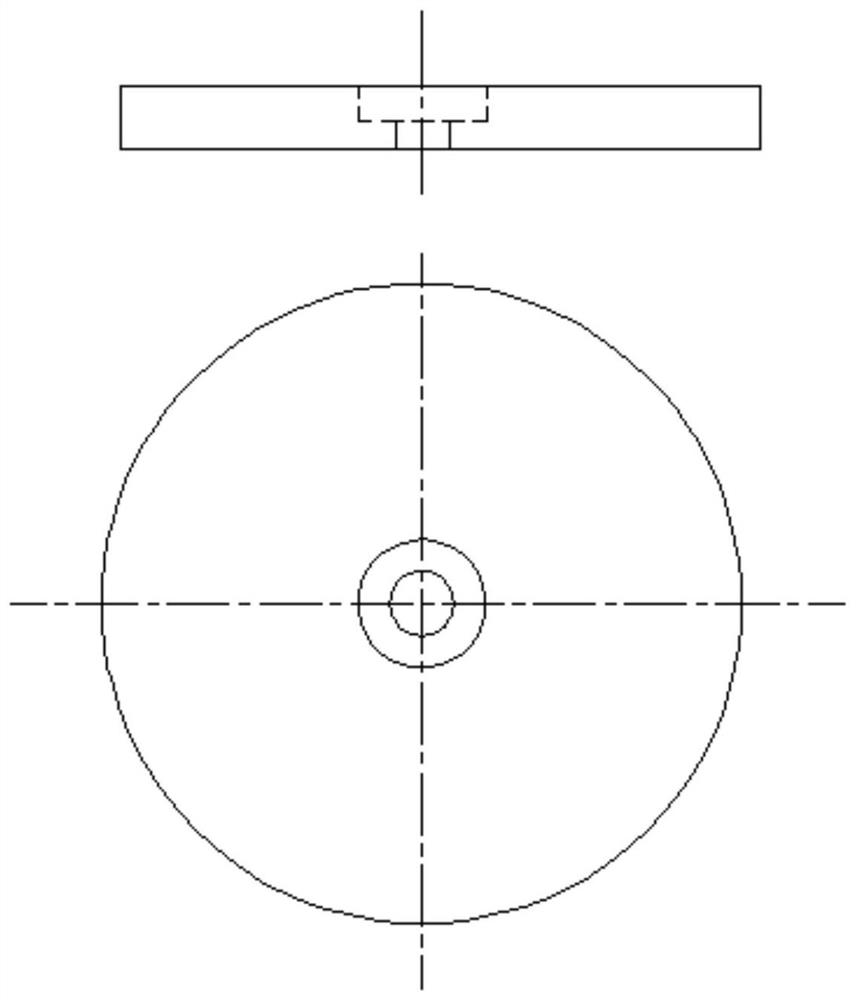

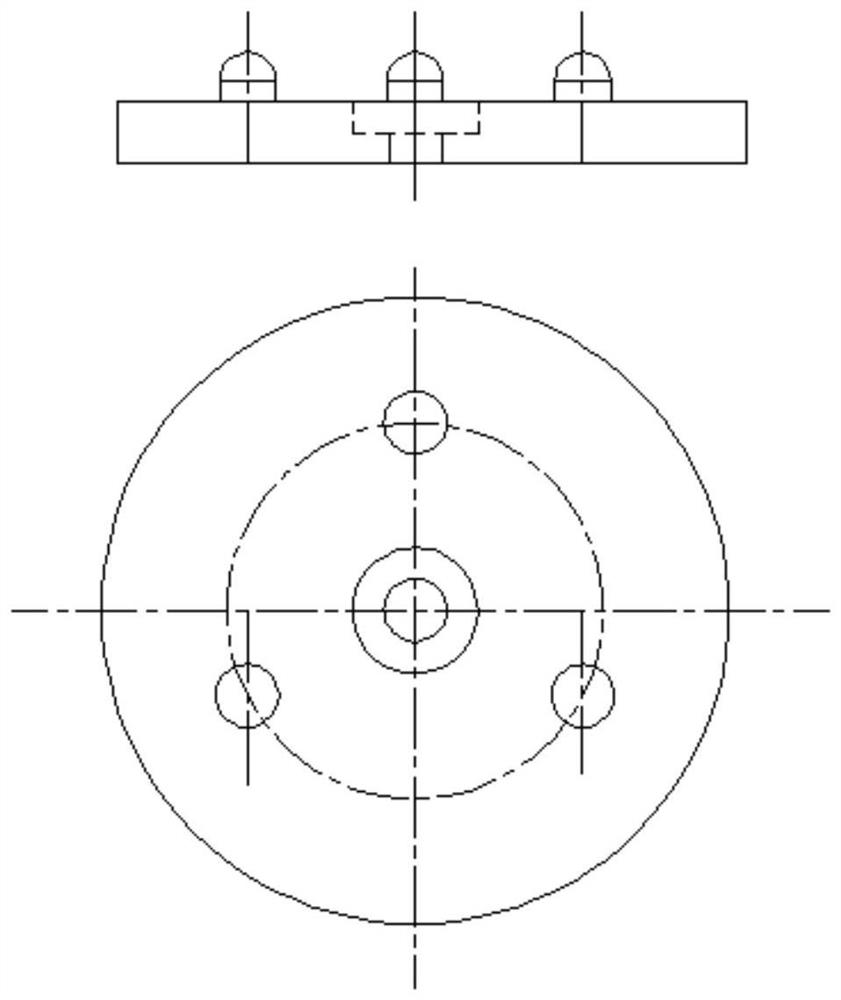

[0019] A position correction device, comprising a base part and a correction part, the correction part is arranged on the base part, the base part is used for leveling the datum, and the correction part is used for receiving the workpiece to be transferred, so that the The workpiece to be transferred is in a leveling state, which is beneficial to the grasping or clamping of the manipulator.

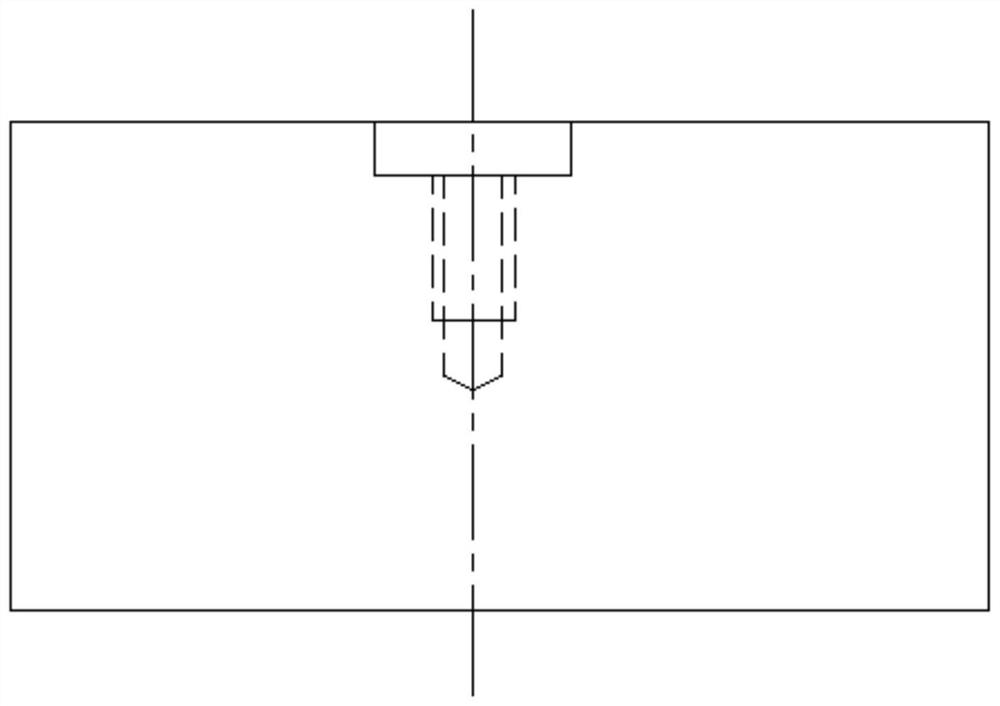

[0020] Such as figure 1 Shown is a schematic diagram of the base, which is a flat plate with a counterbore in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com