Temperature-control anti-cracking curing method for mass concrete

A large-volume concrete, temperature control and anti-cracking technology, applied to thermometers, applications of thermometers, and parts of thermometers, etc., can solve problems such as high pre-embedded costs, limited cooling range of cooling pipes, and easy internal cracks in concrete, etc., to achieve Avoid temperature cracks, reliable performance, and reduce the effect of internal and external temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

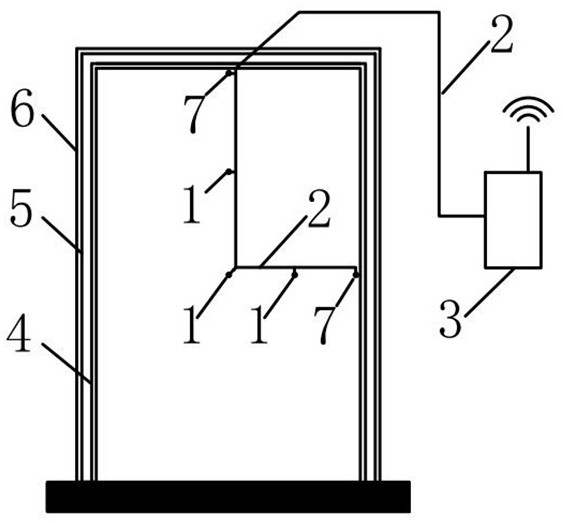

[0020] A temperature-controlled anti-crack maintenance method for C60 mass concrete arch ribs, such as figure 1 As shown, the specific steps are as follows:

[0021] A. Control the temperature of raw materials to meet the following requirements: the temperature of cement and mineral powder is ≤60°C, the temperature of fly ash is ≤40°C; the temperature of sand and gravel is ≤28°C, the water temperature is ≤10°C, and the water reducer is at room temperature;

[0022] B. According to the design strength of the concrete, mix the above raw materials according to the design ratio, and the temperature of the concrete after it is transported to the site is ≥5°C and ≤28°C; the specific weight ratio formula of the concrete is:

[0023] Cement: fly ash: mineral powder: sand: gravel: water: water reducing agent = 298: 100: 100: 749: 1079: 135: 7.47;

[0024] C. Embed three first temperature sensors 1 at the inner center of the concrete to measure the internal temperature value of the con...

Embodiment 2

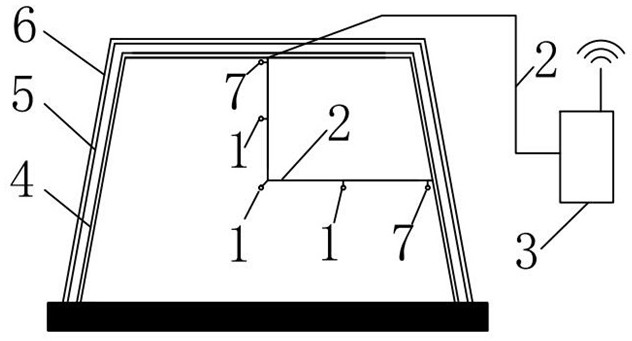

[0031] A temperature-controlled anti-crack maintenance method for a C50 mass concrete abutment, such as figure 2 As shown, the specific steps are as follows:

[0032] A. Control the temperature of raw materials to meet the following requirements: the temperature of cement and mineral powder is ≤60°C, the temperature of fly ash is ≤40°C; the temperature of sand and gravel is ≤28°C, the water temperature is ≤10°C, and the water reducer is at room temperature;

[0033] B. According to the design strength of the concrete, mix the above raw materials according to the design ratio, and the temperature of the concrete after it is transported to the site is ≥5°C and ≤28°C; the specific weight ratio formula of the concrete is:

[0034] Cement: fly ash: mineral powder: sand: gravel: water: water reducer = 264: 130: 86: 751: 1081: 135: 5.28;

[0035] C. Embed three first temperature sensors 1 at the central position of the concrete to measure the internal temperature of the concrete; r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com