A self-supporting ring-shaped closed environmental protection precast concrete wall panel

A prefabricated concrete, annular closed technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of easy breakage of annular concrete wall panels, and achieve the effects of not being easily broken, improving meshing stability, and improving firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-5 The application is described in further detail.

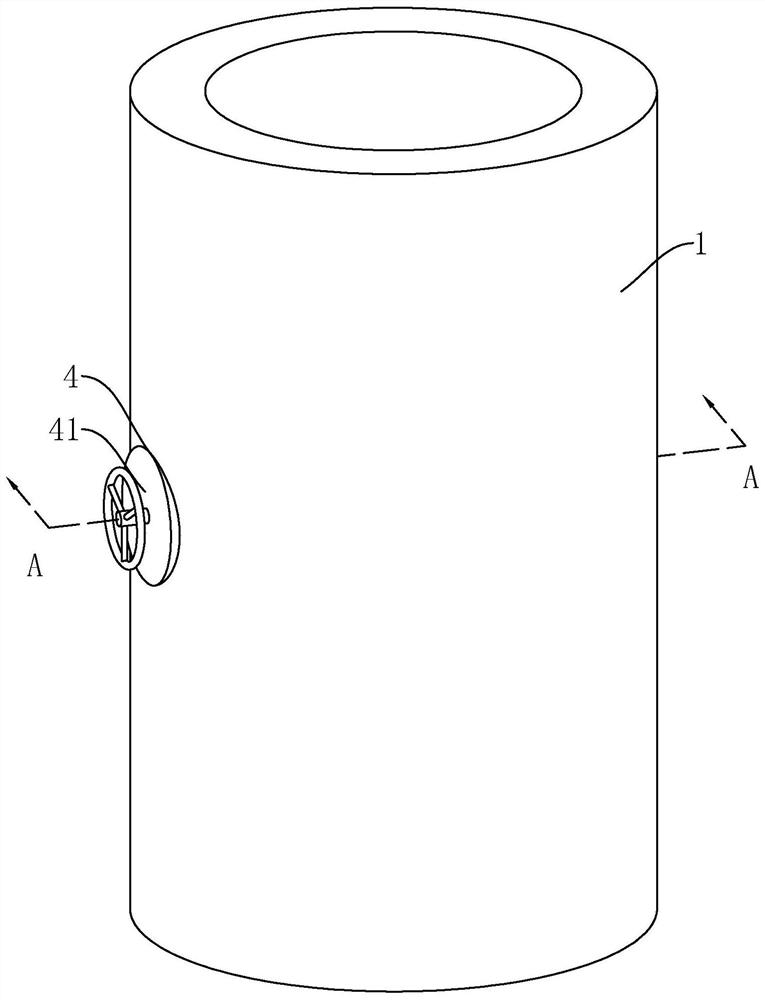

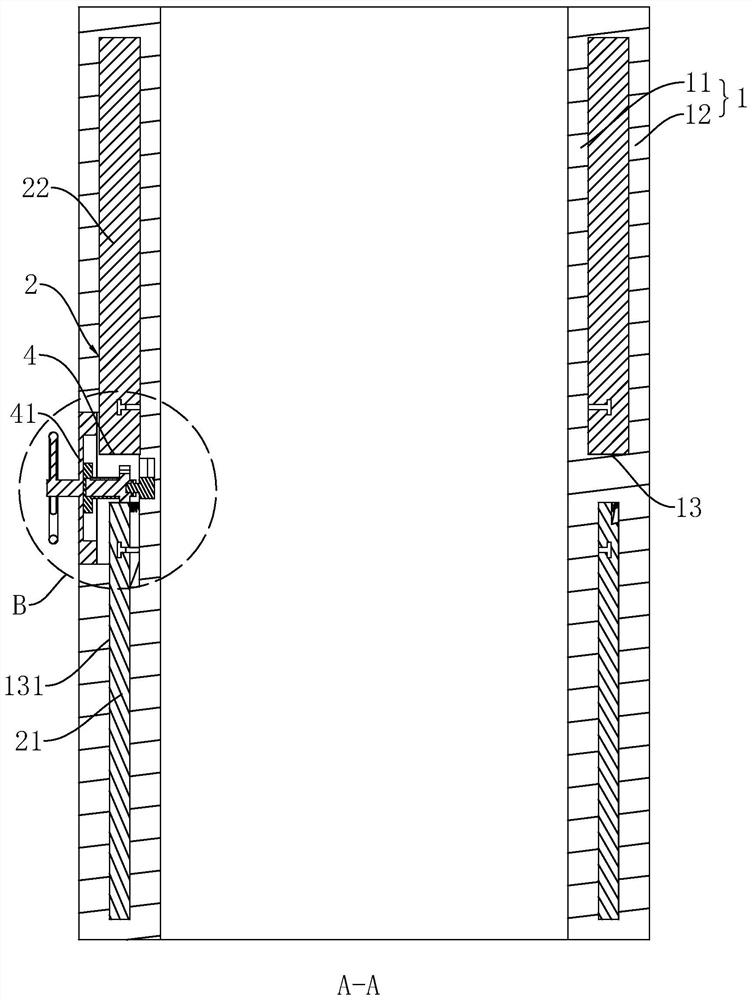

[0036] The embodiment of the present application discloses a self-supporting annular closed environment-friendly prefabricated concrete wall panel. refer to figure 1 , figure 2 The self-supporting ring-shaped closed environment-friendly prefabricated concrete wall panel includes a wall body 1 and a supporting steel structure 2 embedded in the wall body 1 . The wall body 1 includes a cylindrical inner wall layer 11 and an outer wall layer 12 arranged coaxially, and the supporting steel structure 2 is arranged between the inner wall layer 11 and the outer wall layer 12 .

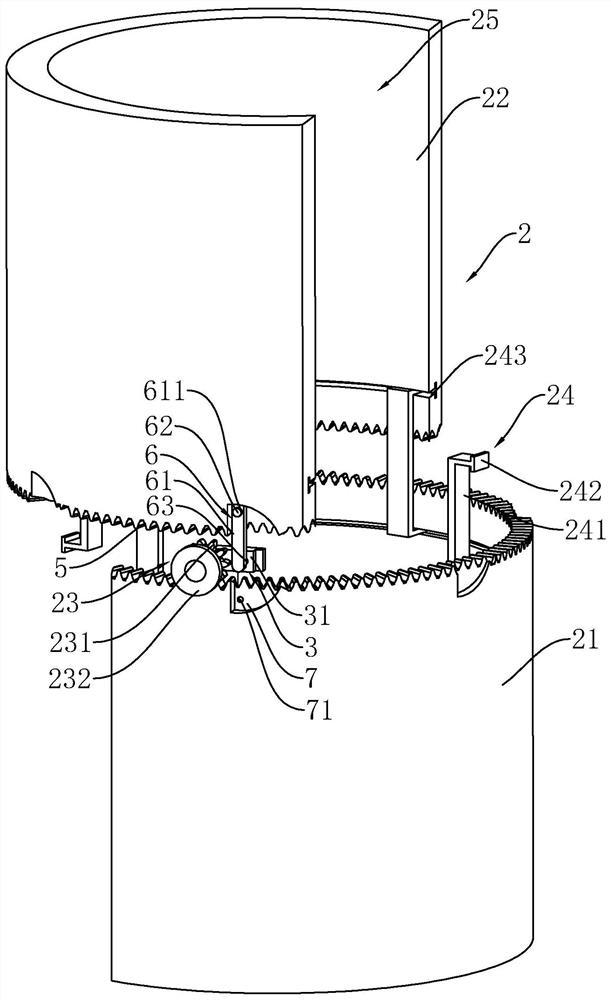

[0037] refer to image 3 The supporting steel structure 2 includes a first broken ring steel plate 21, a second broken ring steel plate 22, a driving assembly 23 for driving the first broken ring steel plate 21 and the second broken ring steel plate 22 to rotate and connecting the first broken ring steel plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com